Rubber surface air-blowing device for drying and compounding machine

A technology of blowing device and drying machine, applied in printing device, lamination auxiliary operation, printing and other directions, can solve the problems of increasing the dosage of preparations such as viscose, the font becoming blurred, and trouble, so as to avoid the occurrence of paste code, Ensure normal and reliable operation, avoid the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

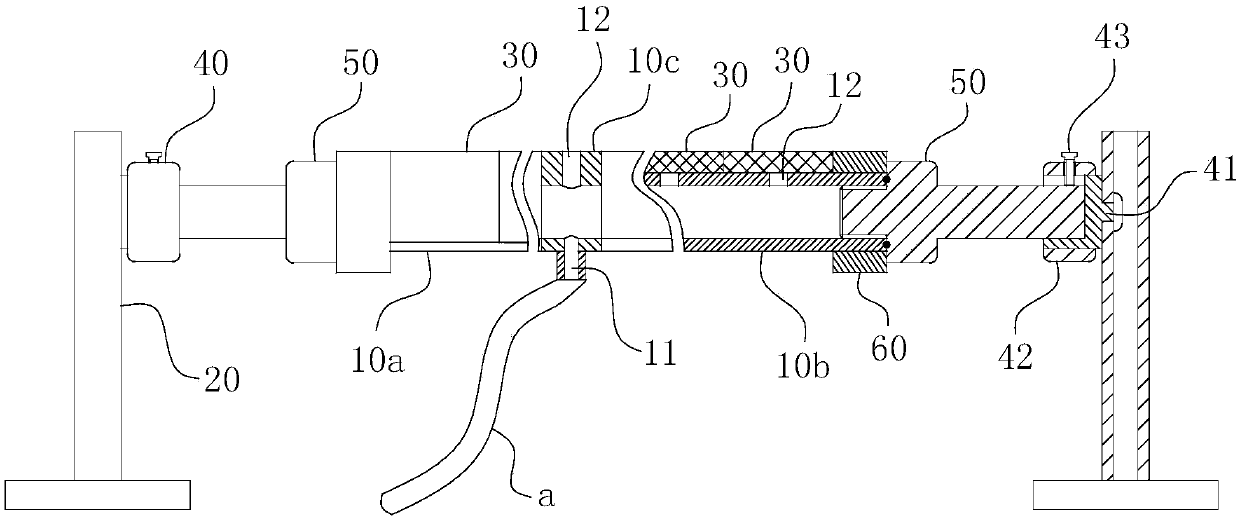

[0029] For ease of understanding, the specific structure and working method of the present invention are described as follows in conjunction with the accompanying drawings:

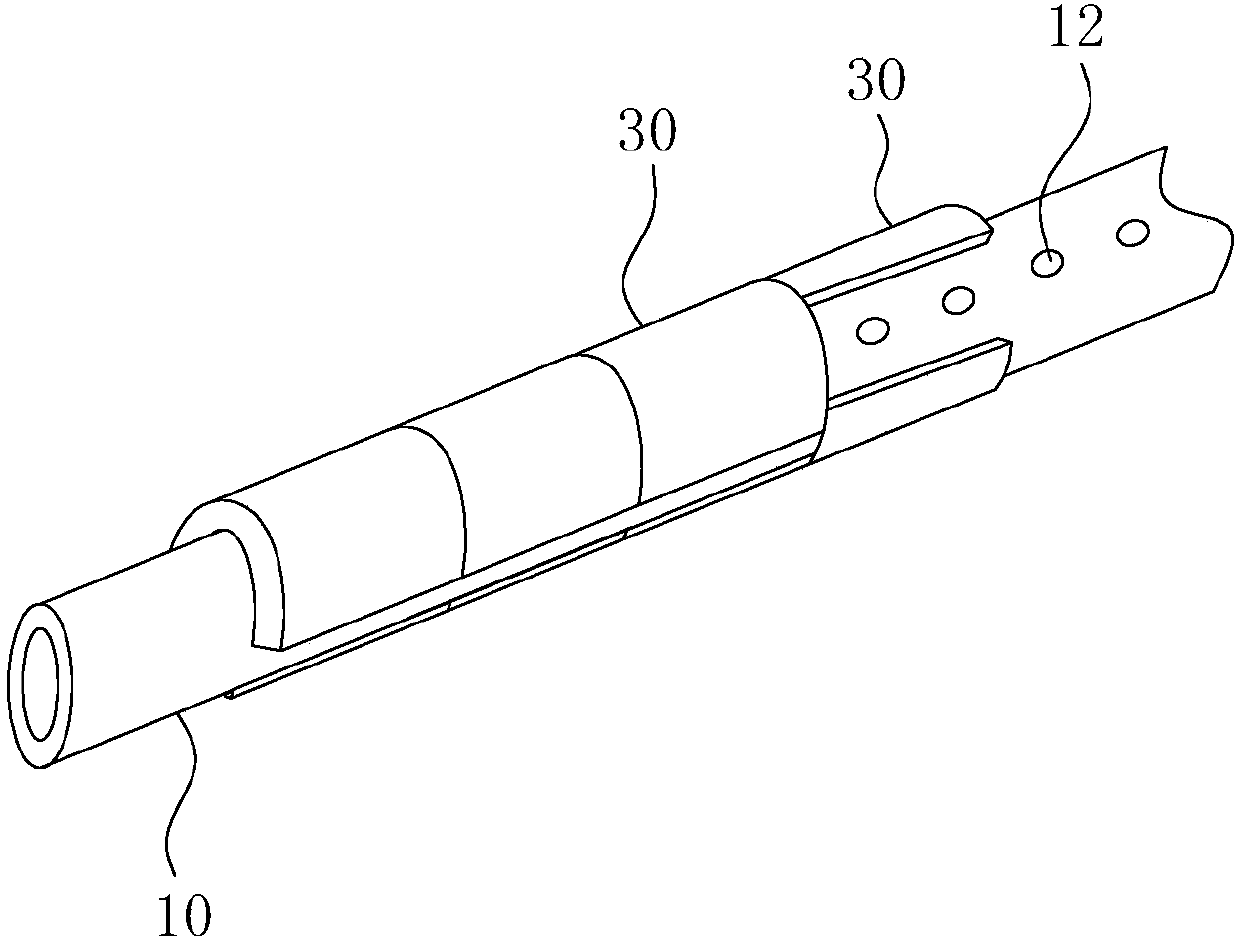

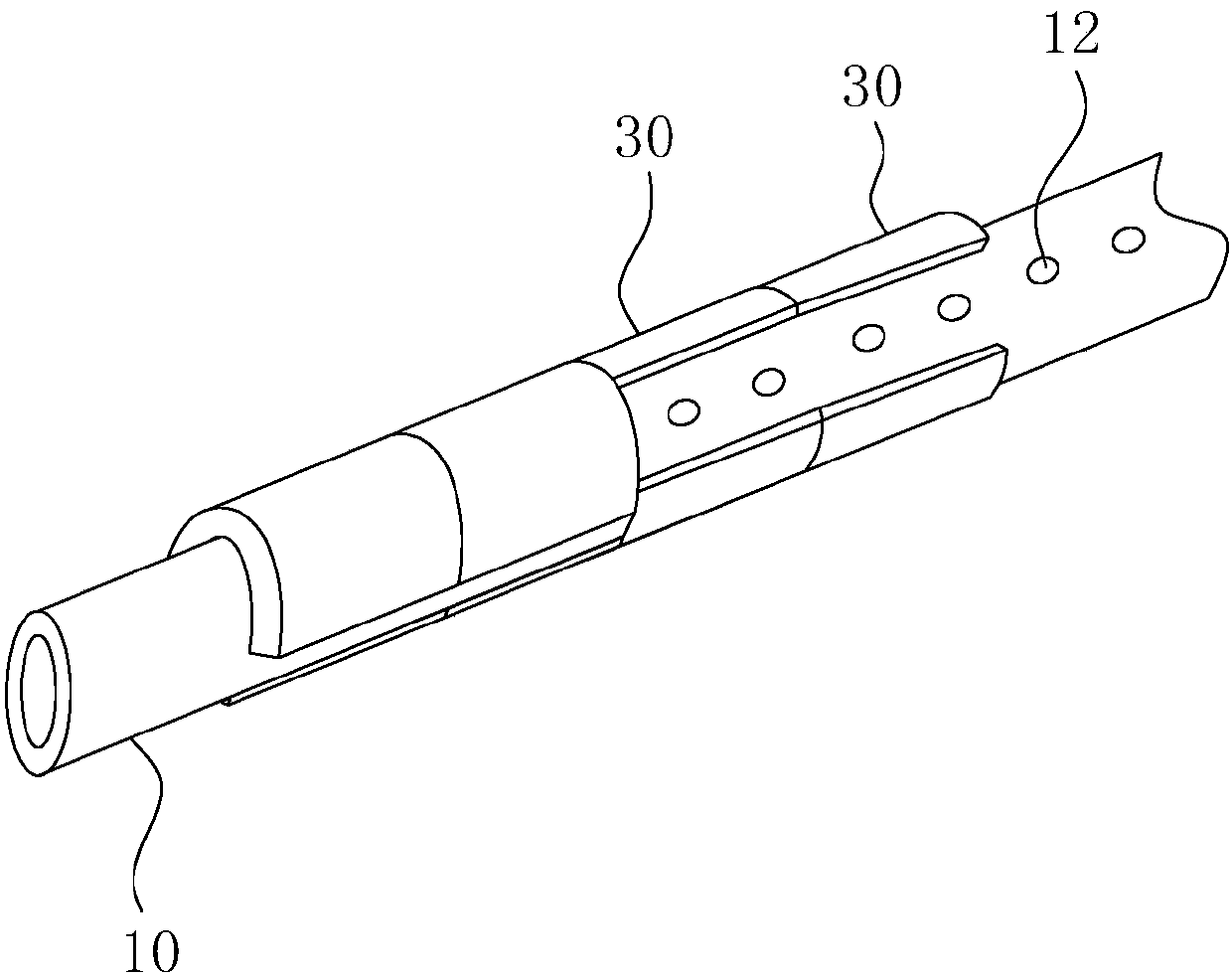

[0030] Concrete structure of the present invention refers to Figure 1-6 As shown, its main structure includes bracket 20, pipe end connector 40, connecting rod 50, left air pipe 10a, right air pipe 10b, connecting ring 10c, windshield ring 30 and backing ring 60, wherein:

[0031] Such as figure 1 As shown, the left air duct 10a and the right air duct 10b are arranged coaxially with each other and coaxially separated at the two ends of the connecting ring 10c, thereby forming the air duct 10 together with the connecting ring 10c. The connecting ring 10c itself has an air inlet 11, so as to communicate with external air supply equipment through the air inlet pipe a. A number of air outlets 12 are arranged axially in sequence on the connecting ring 10c and the left air duct 10a and the right air duct 10b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com