Control method for steady and efficient operation of ship chamber of hydraulic ship lift in go-out-of-water and go-into-water processes

A control method and high-efficiency operation technology, which is applied in the vertical lifting of ship machinery, ship lifting devices, buildings, etc., can solve the problems of large variation of downstream water level, rapid rate of change, difficult operation, etc., and achieves improved operation efficiency and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

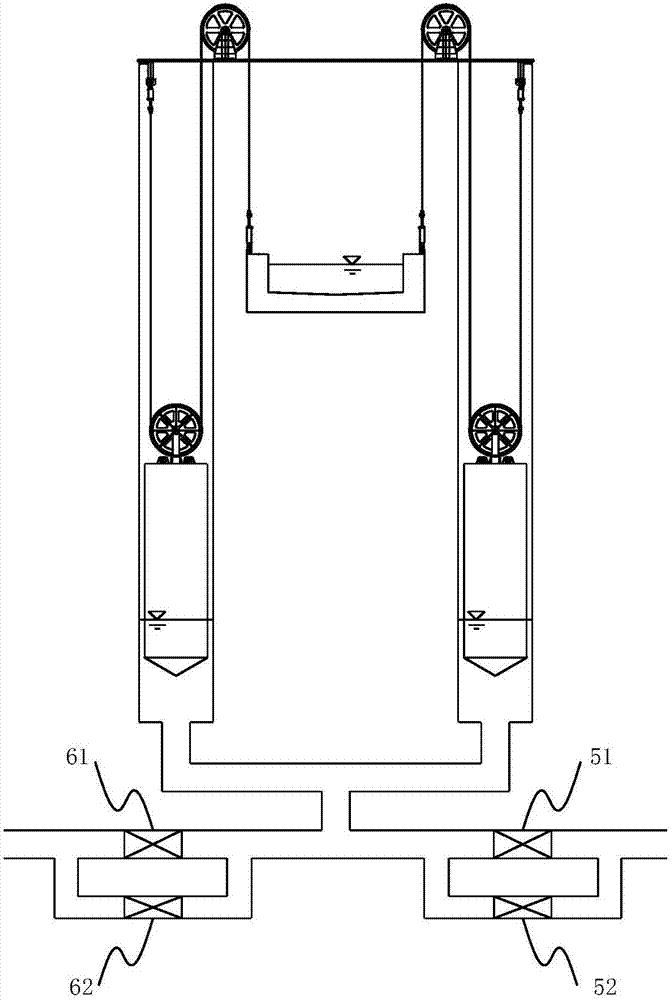

[0040] In this embodiment, the method of the present invention is applied to the control of a hydraulic ship lift.

[0041] 1) Out of the cabin

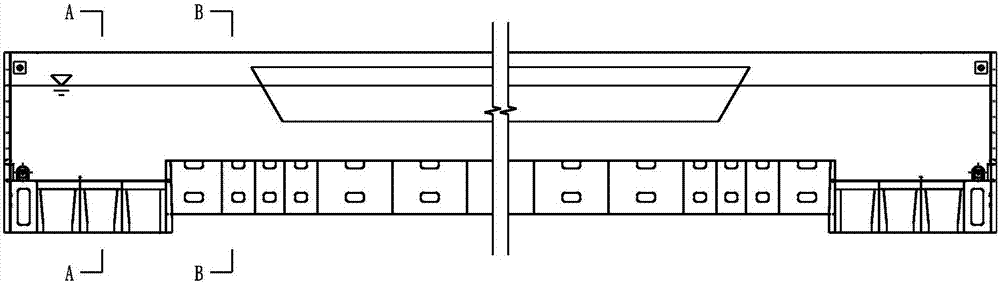

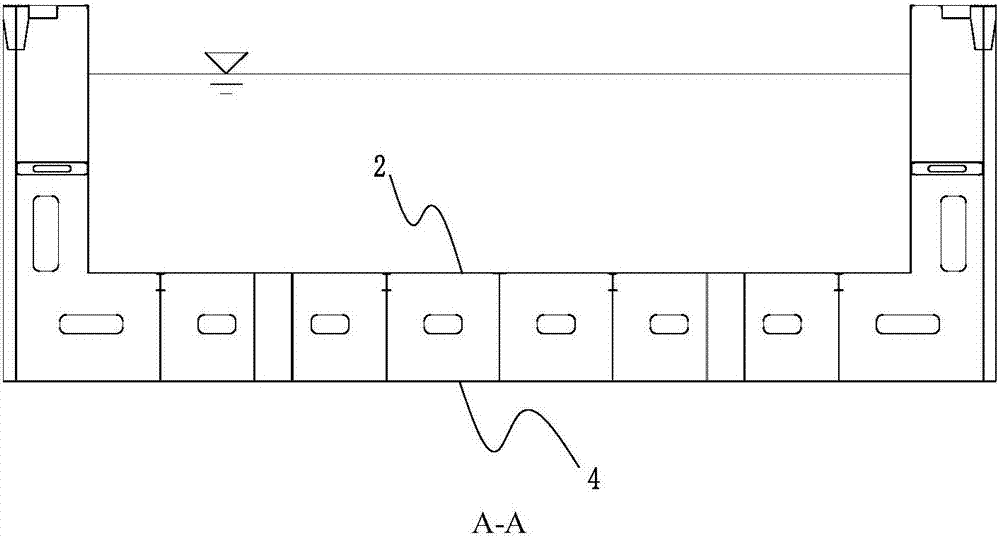

[0042] See Figure 2 to Figure 5 , the key nodes of the water outlet of the cabin include: the moment of water outlet start, the water outlet of the wedge-shaped body at the bottom of the cabin 1, the water outlet of the bottom 2 of the lying door at both ends of the cabin, the water outlet of 3 at the bottom flange of the cabin, and the 4 bottom flange of the lying door at both ends of the cabin out of water.

[0043] The water discharge valve of the cabin of the hydraulic ship lift includes the main valve 51 and the auxiliary valve 52. The control method and the speed process line of the cabin are as follows: Figure 5 As shown, the operation control flow combines steps 2 and 3. During operation, the water discharge process starts from 0 time and ends at 5'45".

[0044] Step 1: Control the initial opening of the main valve 51 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com