Light leak preventive back light unit of light guide plate

A technology of backlight module and light guide plate, which is applied in the direction of light guide, flat/plate light guide, light guide of lighting system, etc., can solve the problems of edge brightness leakage of backlight module, reducing the average brightness of backlight module, and energy loss of light source, etc. To achieve the effect of reducing light leakage in the gap, reducing the overall thickness and reducing the loss of brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

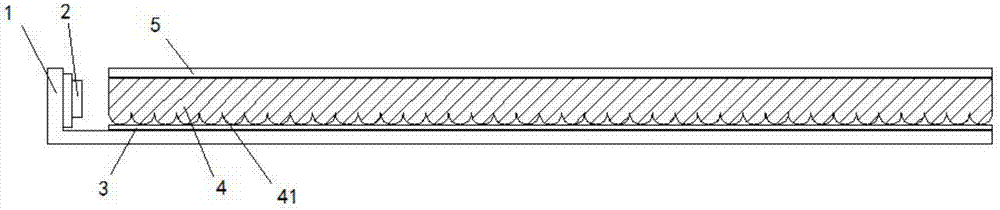

Embodiment 1

[0027] Such as figure 2 As shown, this embodiment provides a backlight module for a light-leakage-proof light guide plate, including a bracket 1, a light source 2, a reflective paper 3, a light guide plate 4, and a diffusion plate 5;

[0028] Described support 1 comprises support short side 11, support long side 12, and support long side 12 left top vertically is provided with support short side 11; Described support short side 11 left side is equipped with light source 2; Described support long side 12 A reflective paper 3 is installed on the upper surface, a light guide plate 4 is placed above the reflective paper 3, a dot 41 is arranged on the lower surface of the light guide plate 4, and a diffusion plate 5 is installed on the upper surface of the antifouling light guide plate 4; the left side of the light guide plate 4 is set There is a semi-elliptical convex lens 42, the lens 42 is in contact with the light source 2, and the bottom of the light guide plate 4 is provided...

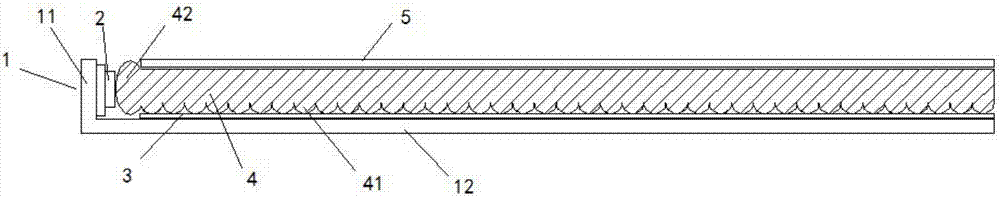

Embodiment 2

[0033] Such as image 3 As shown, this embodiment provides a backlight module for a light-leakage-proof light guide plate, including a bracket 1, a light source 2, a reflective paper 3, a light guide plate 4, and a diffusion plate 5;

[0034] The main difference between this embodiment and Embodiment 1 is that the lens 42 provided on the left side of the light guide plate 4 is a rectangular protrusion, and a rectangular groove 421 corresponding to the light source 2 is provided on the left side of the rectangular protrusion;

[0035] working principle:

[0036] The left side of the lens 42 is provided with a rectangular groove 421, which covers the light source 2 inside; the light emitted by the light source 2 enters the lens 42 through the light emitting surface on the right side of the light source 2, effectively reducing the light passing through the light guide plate 4 and The diffusion plate 5 projects the backlight module from above.

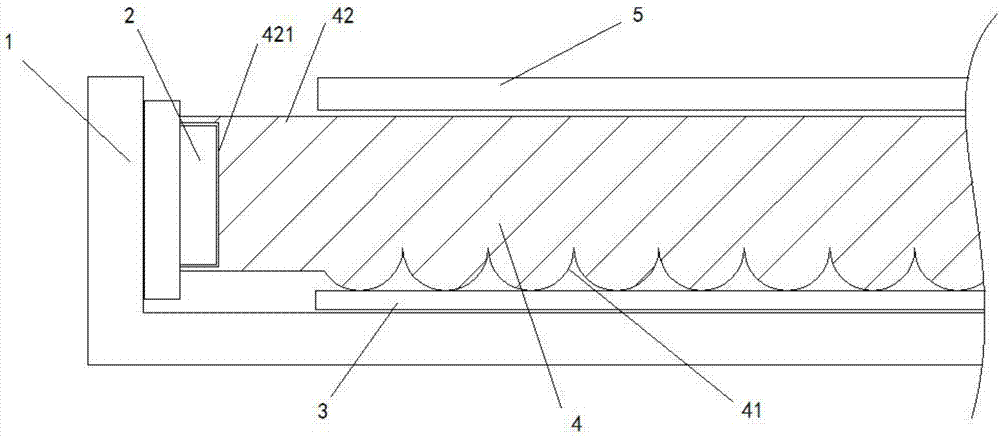

Embodiment 3

[0038] Such as Figure 4 As shown, this embodiment provides a backlight module for a light-leakage-proof light guide plate, including a bracket 1, a light source 2, a reflective paper 3, a light guide plate 4, and a diffusion plate 5;

[0039] The main difference between this embodiment and Embodiment 1 is that the lens 42 arranged on the left side of the light guide plate 4 is a rectangular protrusion, and a tapered groove corresponding to the light source 2 is arranged on the left side of the protrusion, and is arranged on the right side of the tapered groove 431 A tapered cavity 432 in the direction of the tapered groove 431;

[0040] working principle:

[0041] The left side of the lens 42 is provided with a tapered groove 431 corresponding to the light source 2, and the light source 2 is covered inside; The light is refracted on the left side of the tapered cavity 432 to evenly disperse the light and reduce light leakage from the side edge of the light guide plate 4 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com