Lifting vehicle for mold carrying

A technology for lifting carts and lifting wheels, which can be used in trolleys, motor vehicles, multi-axle trolleys, etc., and can solve the problems of time-consuming and laborious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

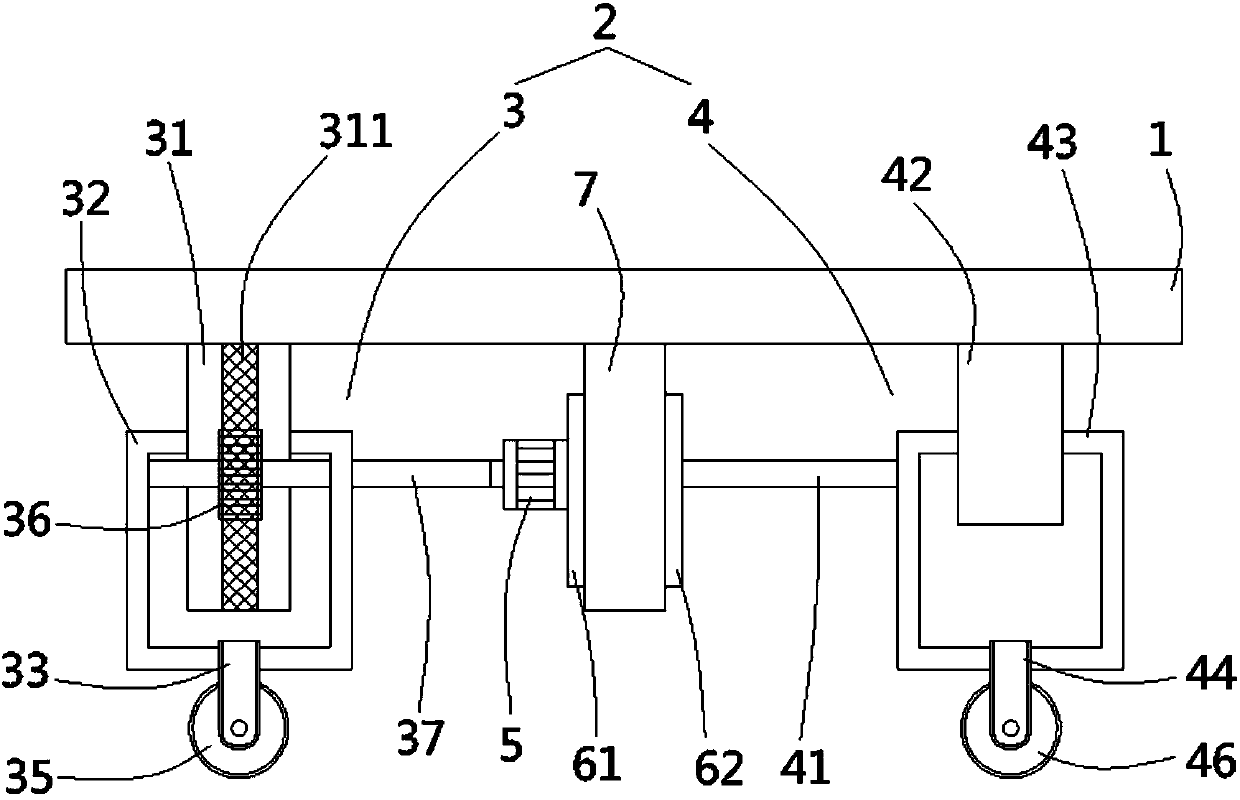

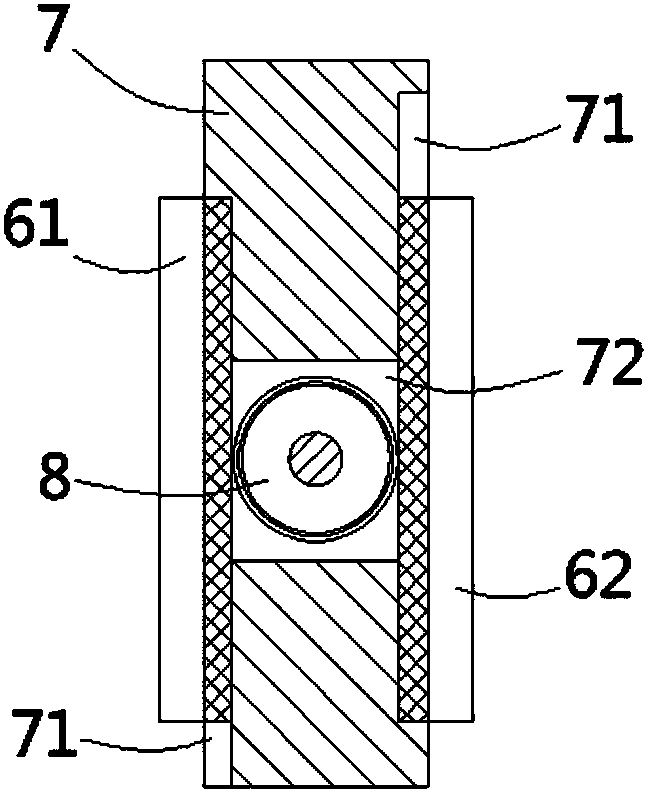

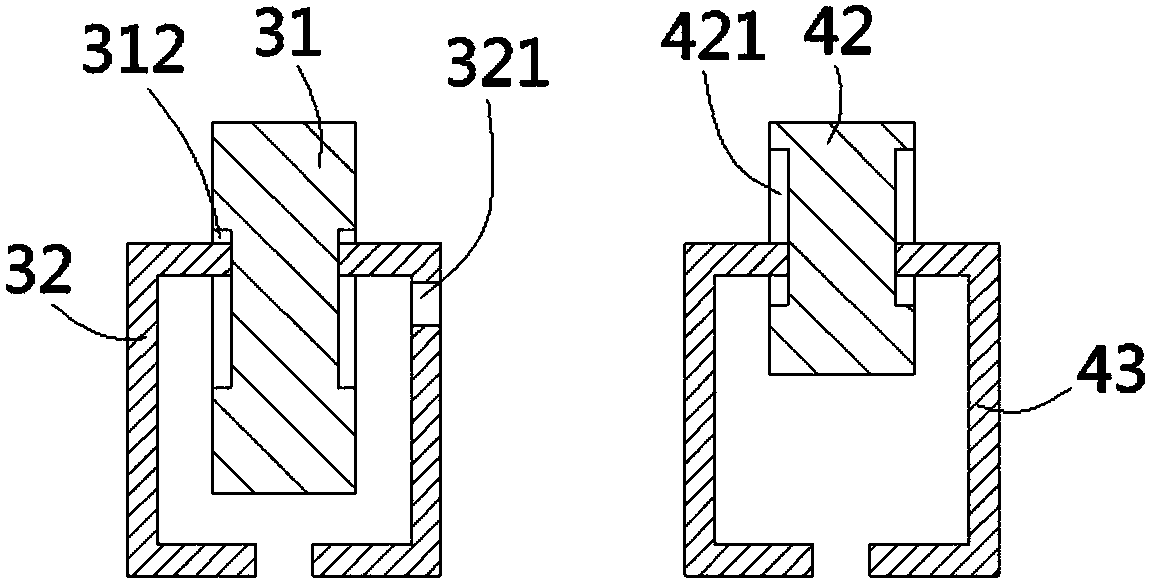

[0020] see figure 1 , figure 2 , Figure 4 According to the present invention, a lifting car for mold handling includes a bottom plate 1, and the four corners of the bottom surface of the bottom plate 1 are provided with lifting wheels 2, and the lifting wheels 2 include a pair of extending wheels arranged on one side of the bottom surface of the bottom plate 1 The wheel 3 and a pair of retractable wheels 4 arranged on the other side of the bottom surface of the bottom plate 1, the extension wheel 3 includes a positioning seat 31 fixed on the bottom surface of the bottom plate 1, and an extension frame 32 inserted on the side wall of the positioning seat 31 , the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com