Boning Apparatus for Thigh of Chicken

A thigh and chicken slaughtering technology, applied in the field of thigh deboning devices for slaughtering chickens, can solve the problems of lowering the input-output ratio, difficult to realize automation of deboning engineering, etc., saving time, minimizing manpower requirements, and minimizing loss rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, preferred embodiments of the present invention capable of concretely achieving the objects of the present invention will be described with reference to the accompanying drawings. In describing the present invention, the same names and the same symbols are used for the same structures, and additional descriptions related thereto are omitted.

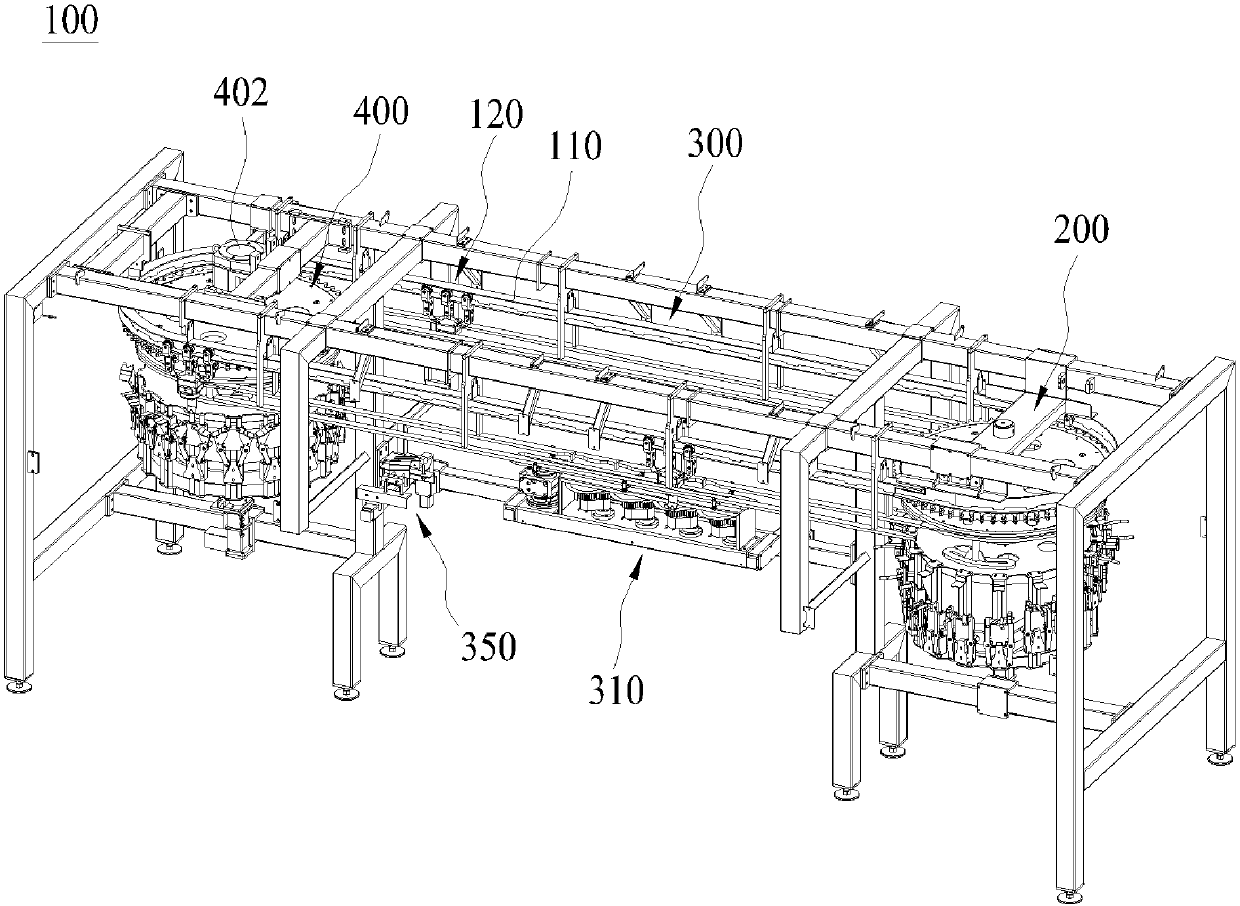

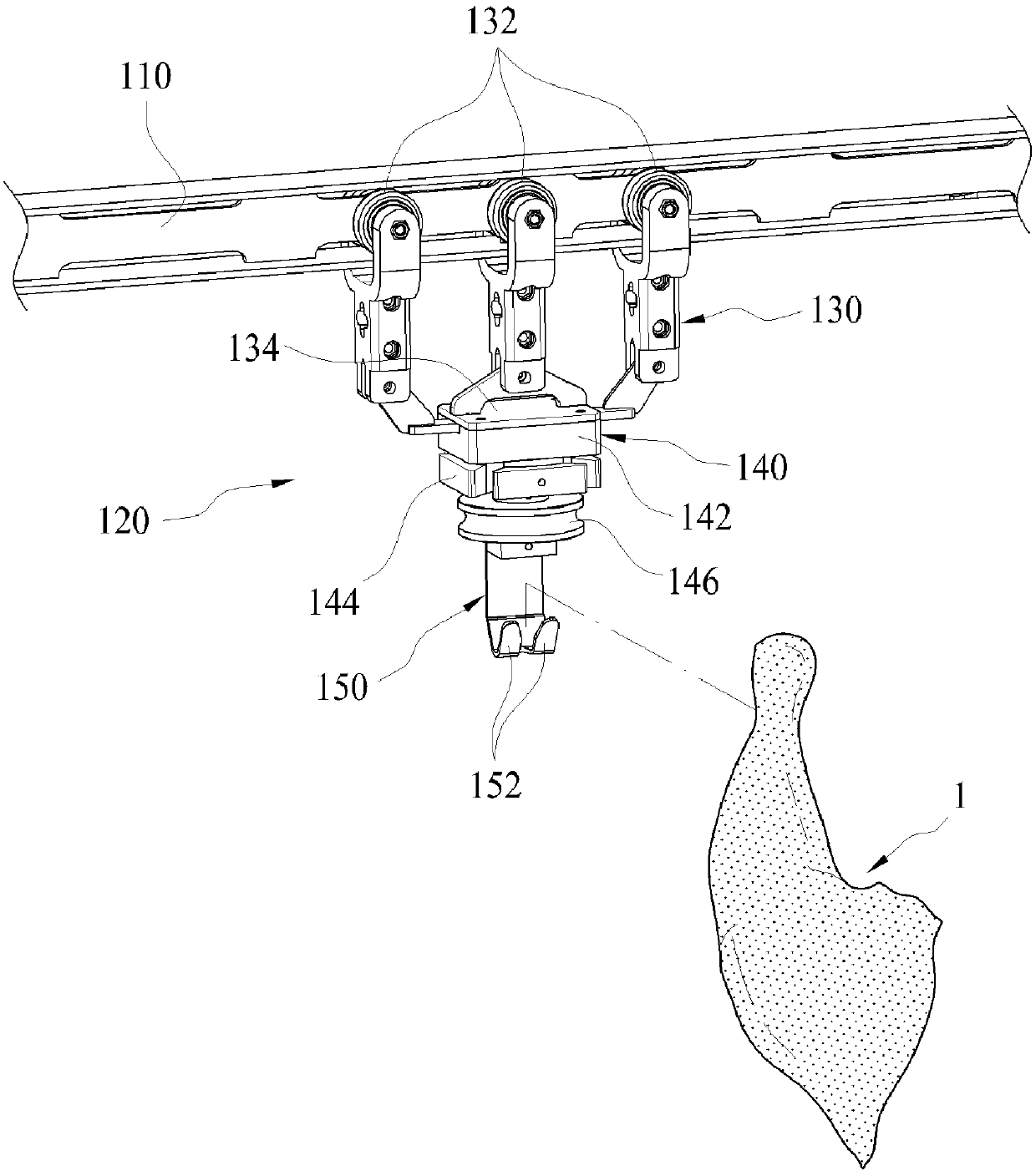

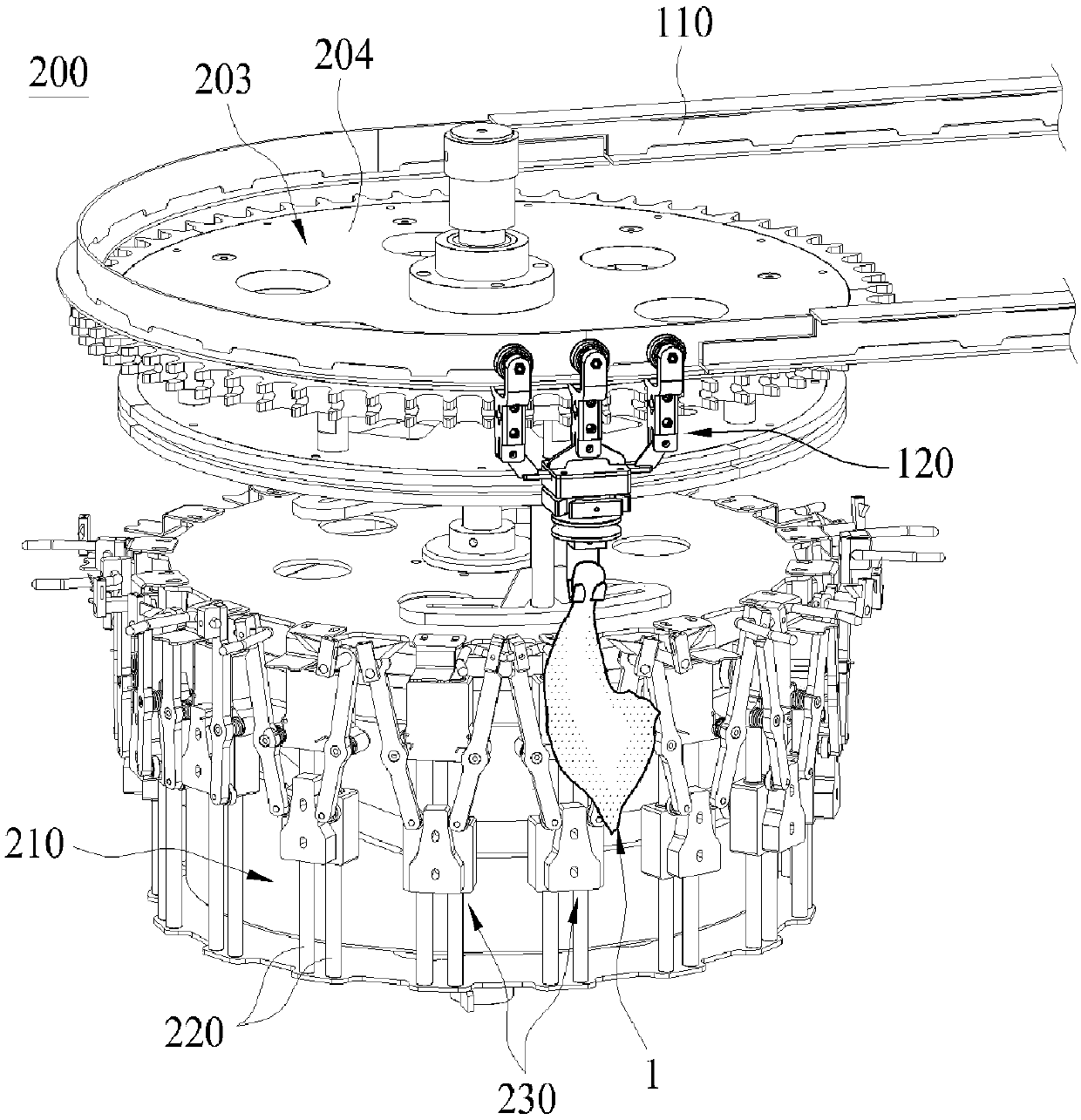

[0055] The present invention is a long horn deboning system for deboning the long horns of a butcher chicken whose drumsticks are connected with thighs, and generally includes a drumstick deboning device 100 (refer to figure 1 ), thigh bone removal device 500 (refer to Figure 20 ).

[0056] That is, the present invention can firstly separate the tympanum bone from the drumstick bone in the long horn by the above-mentioned drumstick bone removal device 100 , and then continue to separate the femur bone from the thigh from which the drumstick bone was separated by the above-mentioned thigh bone removal device 500 . Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com