Supporting padstone reserved hole mold with self-contraction function

A technology of supporting pads and reserved holes, which is applied in the field preparation of formwork/formwork/work frames, building components, construction, etc., can solve the problems of low positioning accuracy, difficult construction, increased time cost, etc., and achieve the overall structure Reasonable and compact, flexible and convenient disassembly and assembly, and the effect of repeated use and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

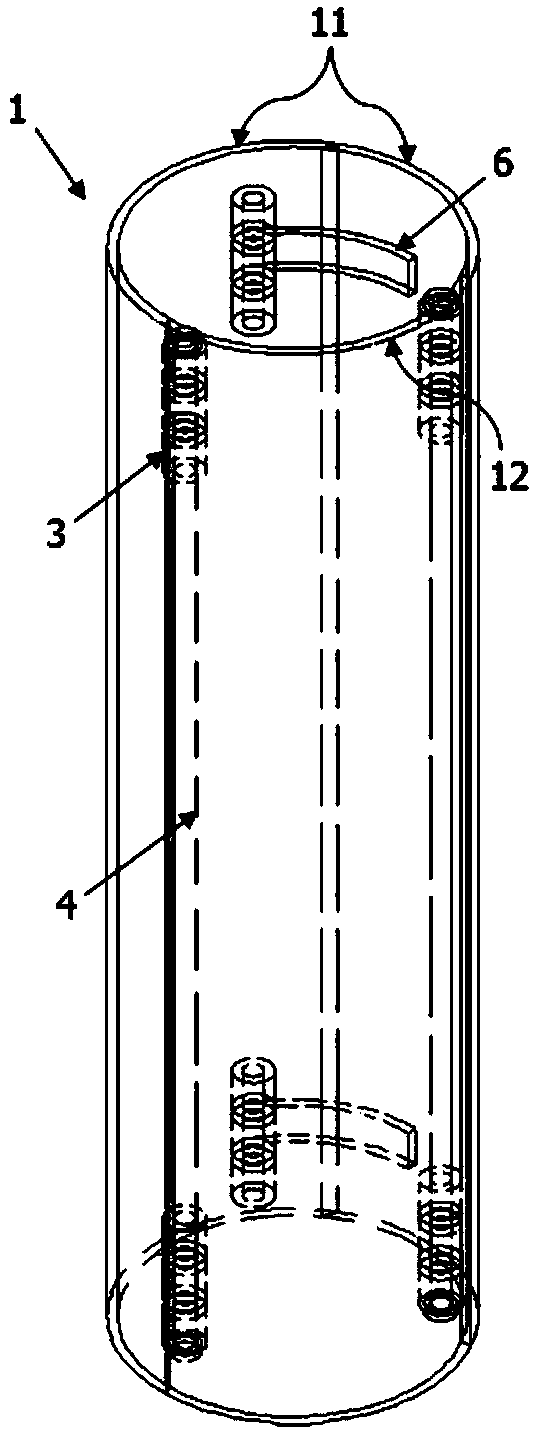

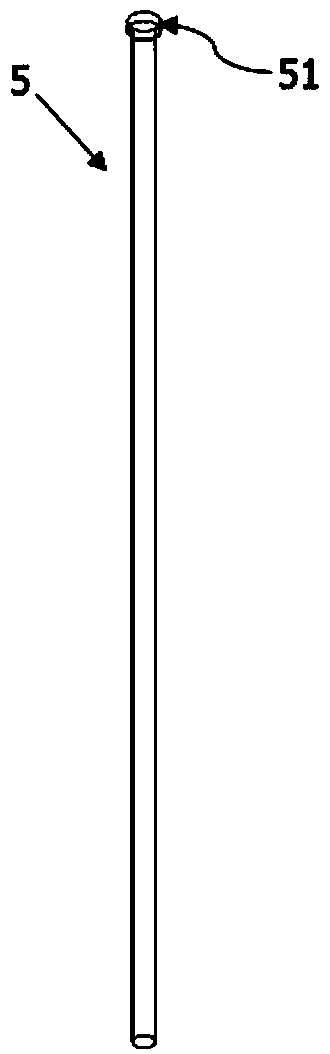

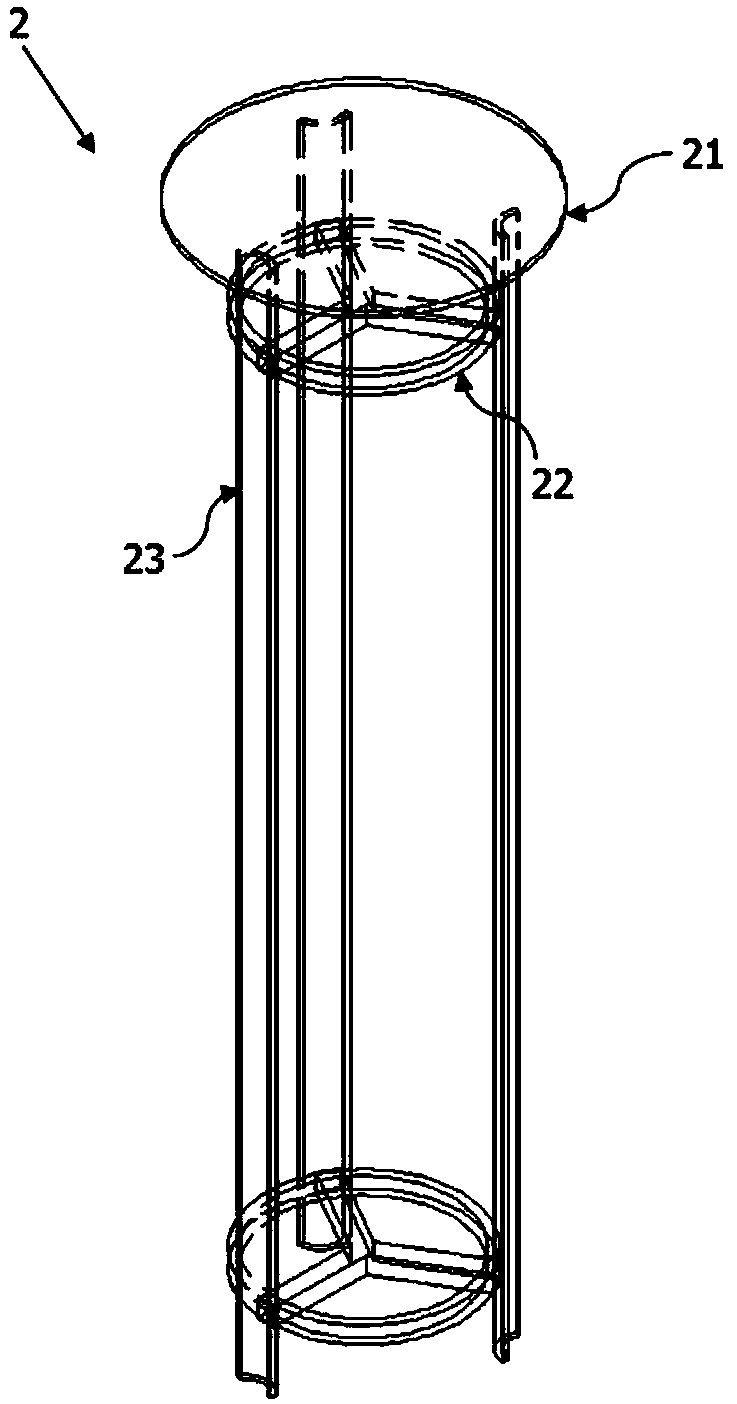

[0022] Shown in conjunction with the accompanying drawings is a specific embodiment of a self-shrinking function of a support pad stone reserved hole mold of the present invention, first of all, it includes a mold body 1, and the mold body 1 includes two sides in a free state. The movable arc plate 11, and an associated arc plate 12 which is arranged between the two movable arc plates 11 and acts as a connection, the movable arc plate 11 and the associated arc plate 12 are spliced together to form a reserved hole for positioning The sleeve, wherein, the outer diameter, thickness and height of the movable arc plate 11 and the associated arc plate 12 are the same, and the outer surface of each arc plate is coated with a release agent for quick removal, further, two The movable curved plates 11 are respectively a first movable curved plate and a second movable curved plate located on the left and right sides of the associated curved plate 12, each of the movable curved plates 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com