Grippers for TBMs and full-face rock boring machines

A technology for roadheaders and boots, which is applied in mining equipment, tunnels, earth-moving drilling, etc., can solve the problems of steel arches that cannot meet the requirements of different spacings, meet the stability requirements, speed up the construction process, and be flexible and convenient to install. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in more detail below in conjunction with the accompanying drawings. It should be noted that the following directional terms such as "up", "down", "left", "right" and the like are described with respect to the drawings, and do not play any restrictive role.

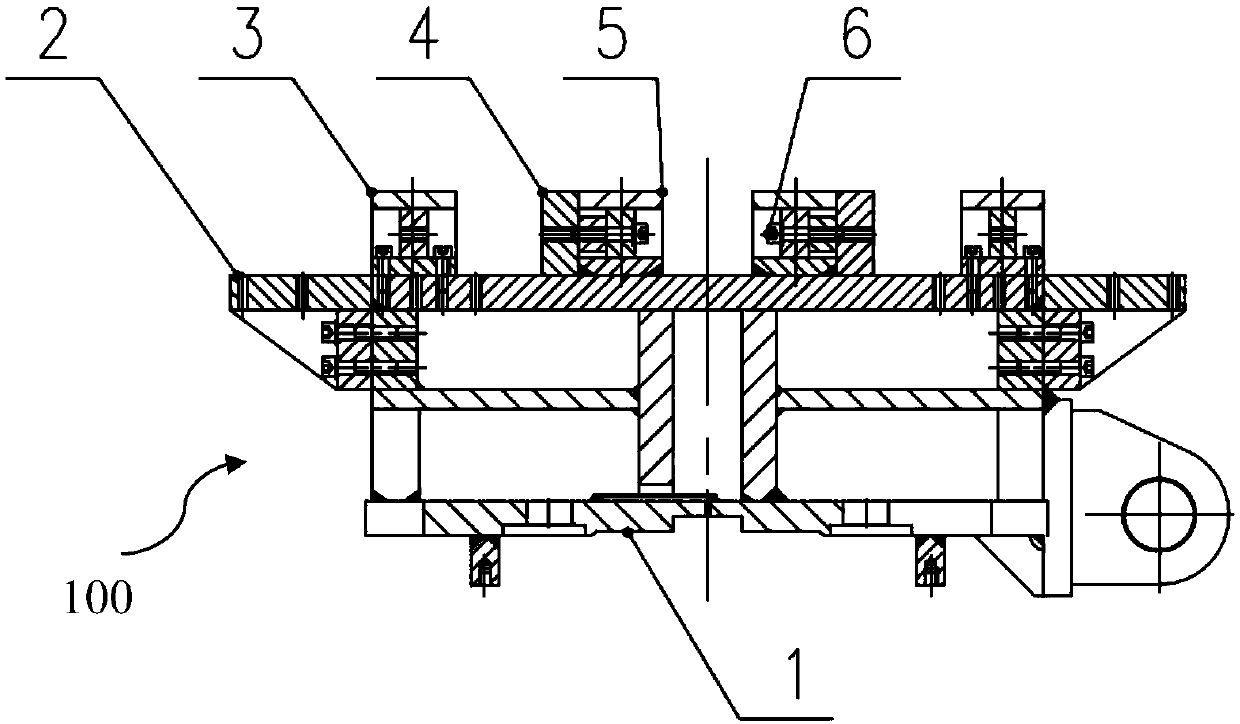

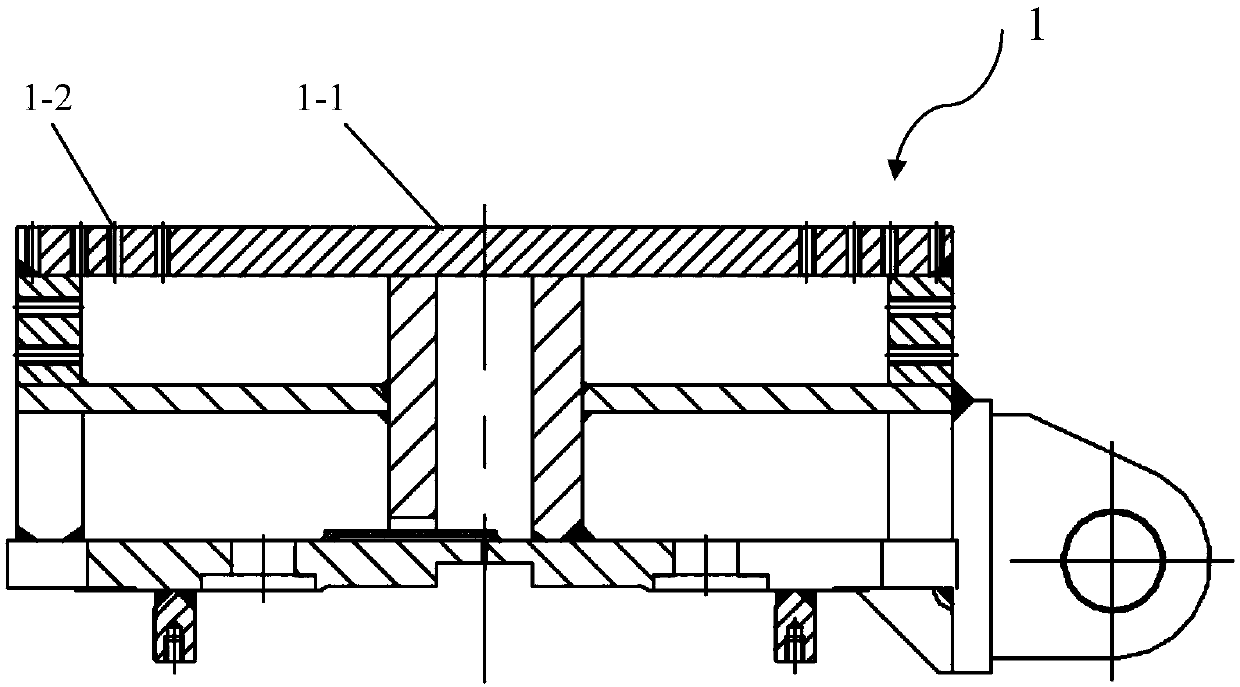

[0036] figure 1 A boot 100 for a TBM according to the invention is shown. As shown in the figure, the boot 100 includes a boot body 1 , which is generally a frame-shaped structure welded by steel plates, and ribs are installed inside. The boot body seat 1 has an arc-shaped top surface 1-1, on which are provided with threaded holes 1-2 with different pitches, see figure 2 . Since the structure of the shoe body seat 1 is well known to those skilled in the art, its detailed introduction is omitted here.

[0037] In practical engineering applications, after the excavation of TBM excavation tunnels, it is necessary to promptly assemble steel arches, bolts, and shotcrete to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com