Turning and spontaneous heating kettle

A hot water bottle, a self-initiated technology, applied to drinking water containers, travel or camping equipment, home appliances, etc., to achieve the effect of simple process, low manufacturing cost, and good development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

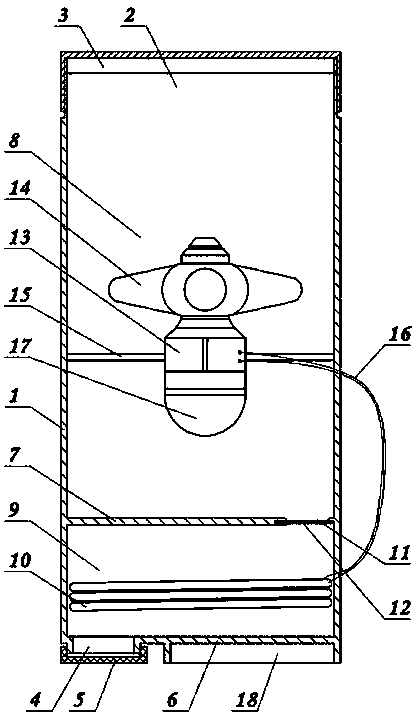

[0019] Embodiment 1: as figure 1 In the flipped self-generating kettle shown, an intermediate layer 7 is provided at the lower part of the cup body 1 , and the cup body 1 is divided into an upper working chamber 8 and a lower heating chamber 9 by the intermediate layer 7 . It can be seen from the figure that the volume of the heating chamber 9 is smaller than that of the working chamber 8 . Therefore, the working chamber 8 can not only store water, but also can do more work for converting electric energy.

[0020] A reversible hydroelectric generator 13 is fixed on the inner wall of the working chamber 8 through a connecting rod, and a resistance wire 10 is installed in the heating chamber 9 . The output power line 16 of the reversible hydroelectric generator 13 is hidden inside the cup body 1 , and the power line 16 is connected to the resistance wire 10 .

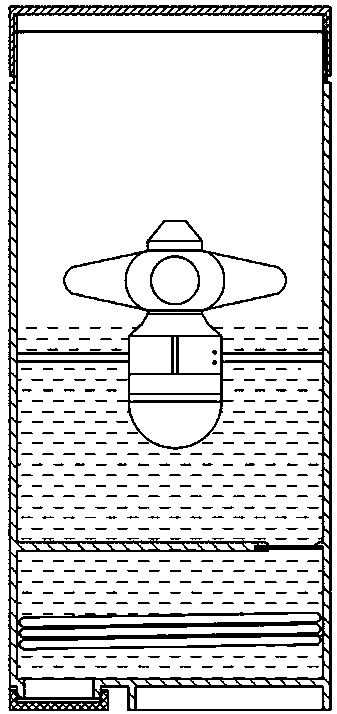

[0021] see figure 2 and Figure 4 As shown, the upper side of the working chamber 8 is provided with a forward cup...

Embodiment 2

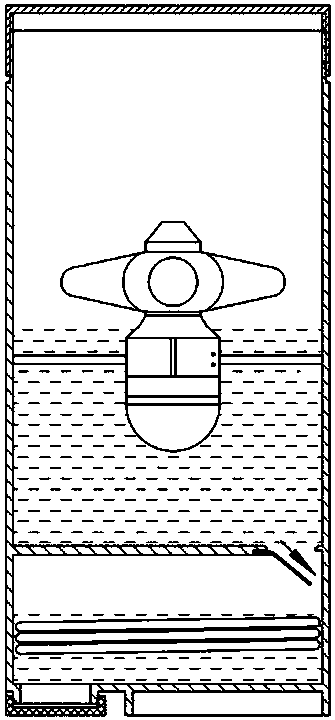

[0025] Embodiment 2: On the basis of Embodiment 1, the reverse cup mouth 4 and the lower cover 5 are arranged on the left side of the cup body 1 , and the drain port 11 and the spring piece 12 are positioned on the right side of the cup body 1 . The two positions are opposite. The purpose of this design is that when pouring hot water outwards, see Figure 5 , at this time, the drain outlet 11 is positioned at the upper side, so the cold water in the working chamber 8 will not directly enter the heating chamber 9, so as to keep pouring out hot water all the time. In an upright position after pouring out hot water see image 3 , the cold water in the working chamber 8 can still enter the heating chamber 9 through the drain port 11 and the shrapnel 12, without affecting the normal drainage function.

Embodiment 3

[0026] Embodiment 3: On the basis of Embodiment 1 or 2, the cup body 1 is a thermos cup with an inner tank, and the bracket for fixing the reversible hydroelectric generator 13 is sleeved on the side wall of the inner tank.

[0027] In order to achieve a better use effect, on the basis of Embodiment 1 or Embodiment 2 or Embodiment 3, a bottom bracket can be arranged below the cup bottom wall 6 of the cup body 1, and the height of the bottom bracket is the same as that of the reverse cup. The mouth 4 and the lower cover 5 have the same height, and the bottom bracket and the reverse cup mouth 4 and the lower cover 5 keep the cup body 1 seated stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com