Adaptive underactuated steering for a three-fingered robotic gripper

An underactuated and robotic technology, applied in the field of robot grippers, can solve problems such as low production efficiency and high cost, and achieve the effect of strong gripping force, large gripping range, and self-locking gripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

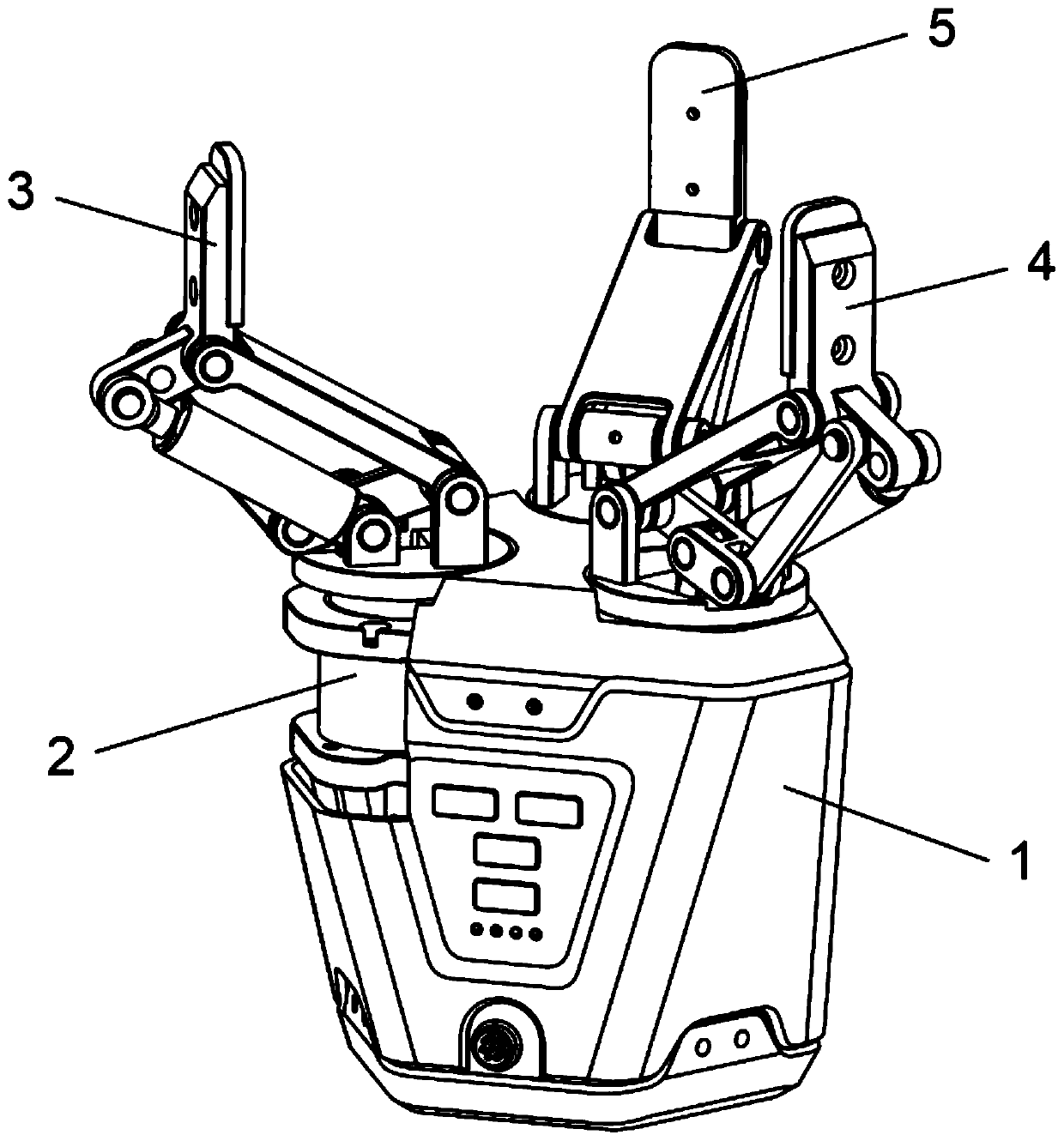

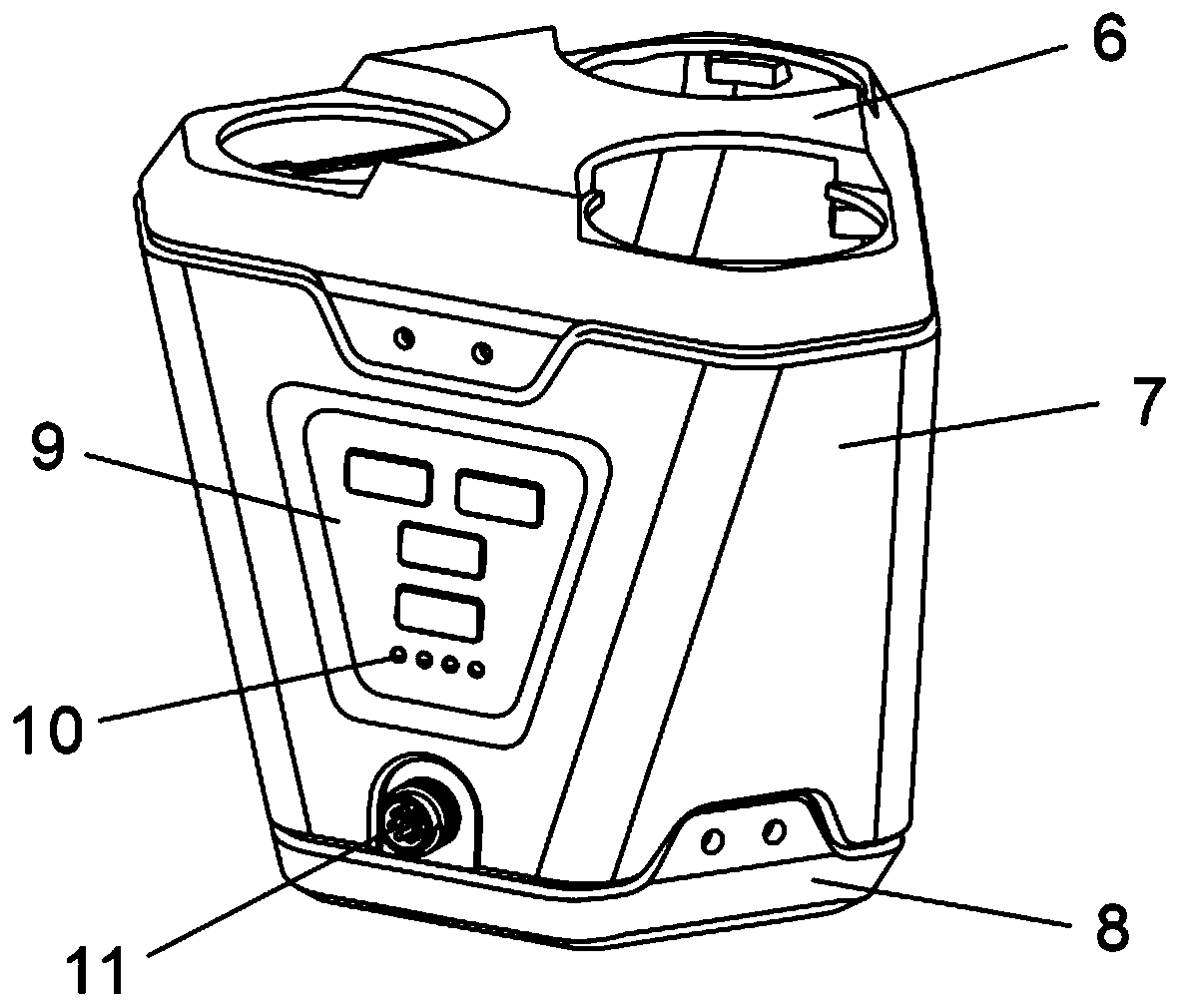

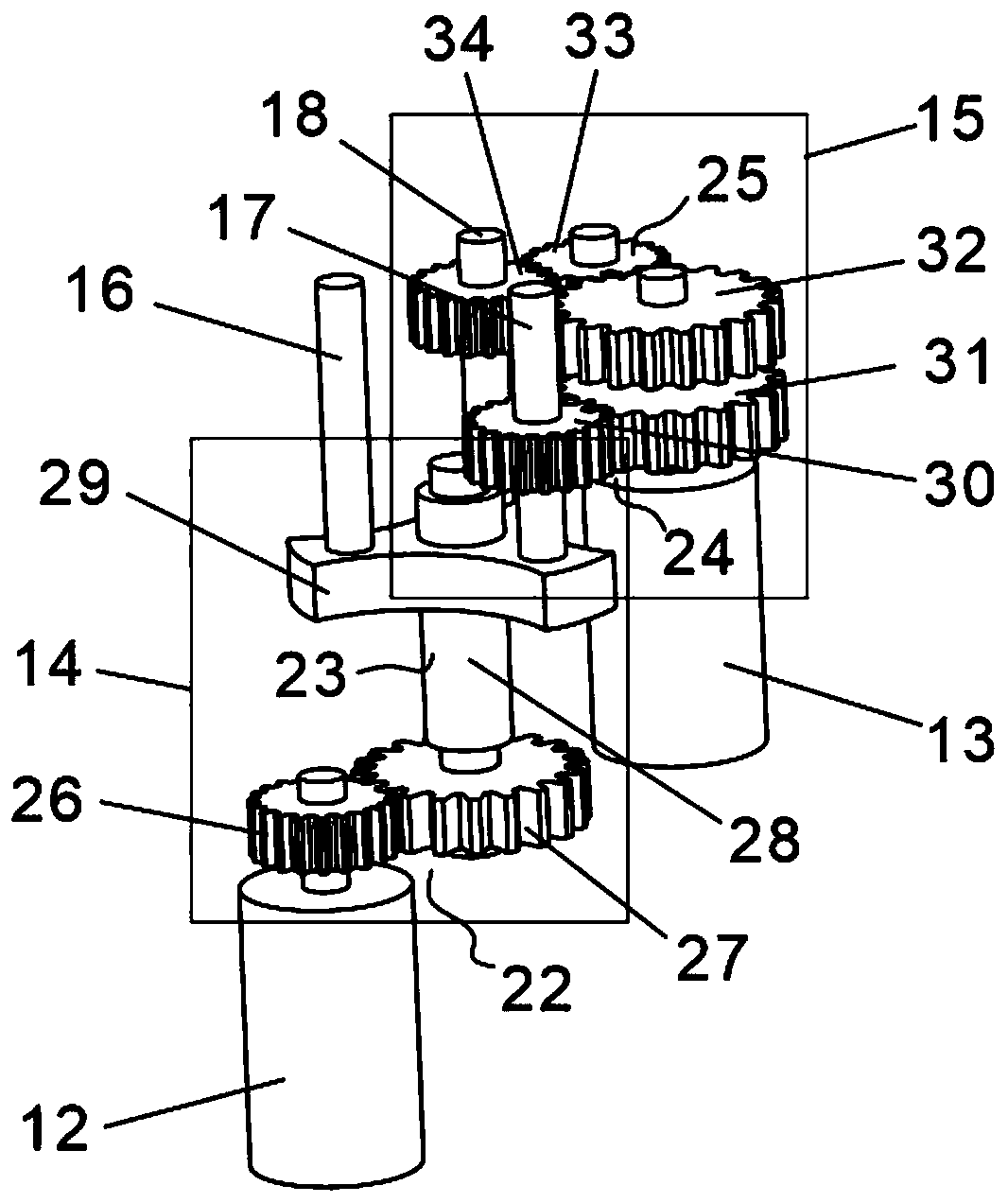

[0044] see figure 1 , figure 2 and image 3 , the invention discloses an adaptive underactuated steering three-finger robot gripper, comprising a gripper housing 1, a drive module 2 and a finger module; the gripper housing 1 includes a housing cover plate 6, a housing box 7 and a fixed Flange 8, one end of the housing box 7 is fixedly connected to the housing cover plate 6, and the other end is connected to the fixed flange 8; the drive module 2 includes a first power transmission system 14, a second power transmission system 15, and a first drive rod 16 , the second drive rod 17 and the third drive rod 18; the first drive rod 16, the second drive rod 17 and the third drive rod 18 are driven by the first drive motor 12 to perform synchronous linear motion along the axis direction of the rod, and the first The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com