Novel roller shutter door structure for automobile storage box

A technology for car storage boxes and rolling doors, which is applied in the passenger space and other directions, can solve the problems of leaf falling off, rolling door shaking, and increased manufacturing costs, and achieve reasonable and uniform extrusion force, avoid jamming, and reduce sliding resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

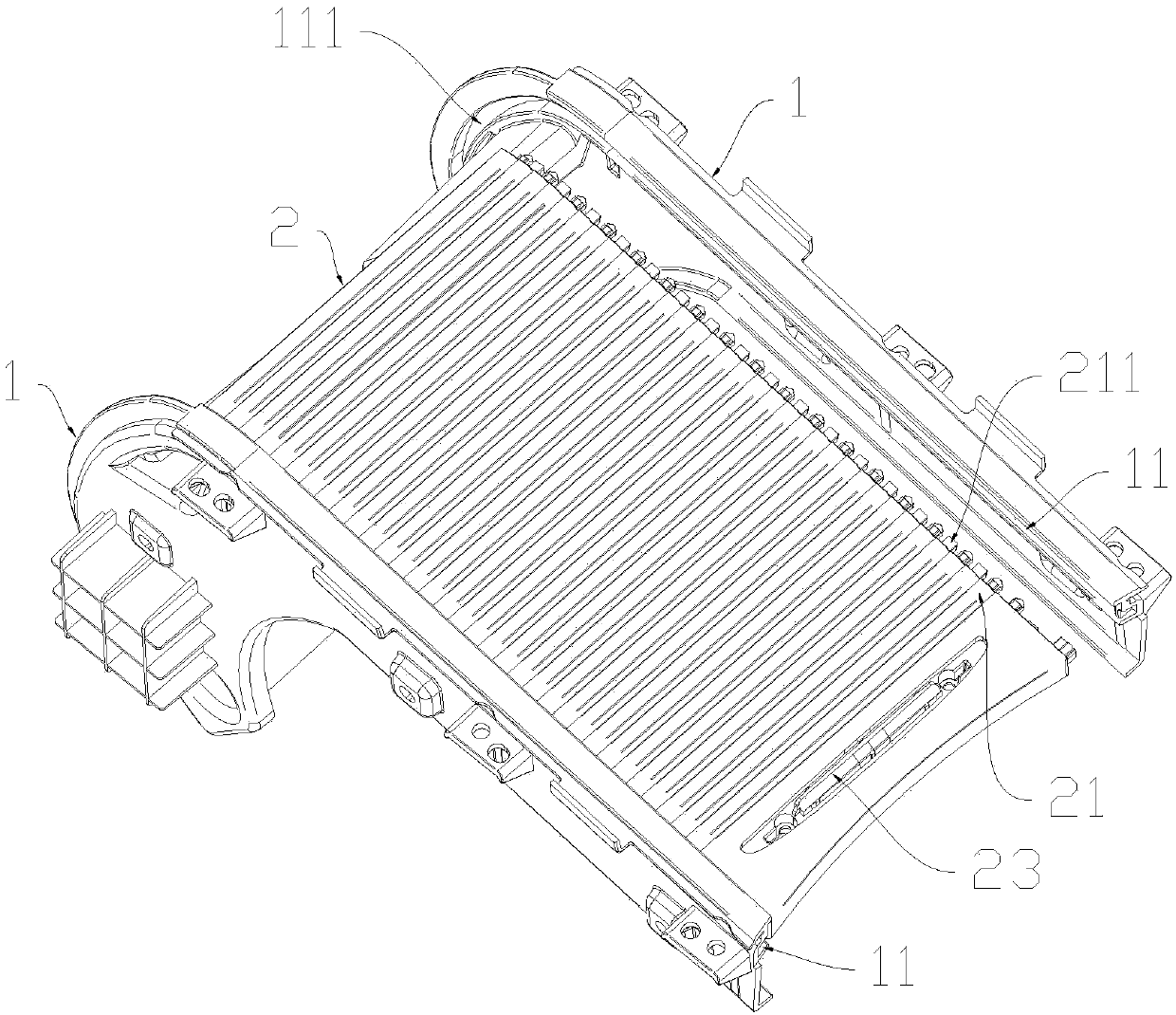

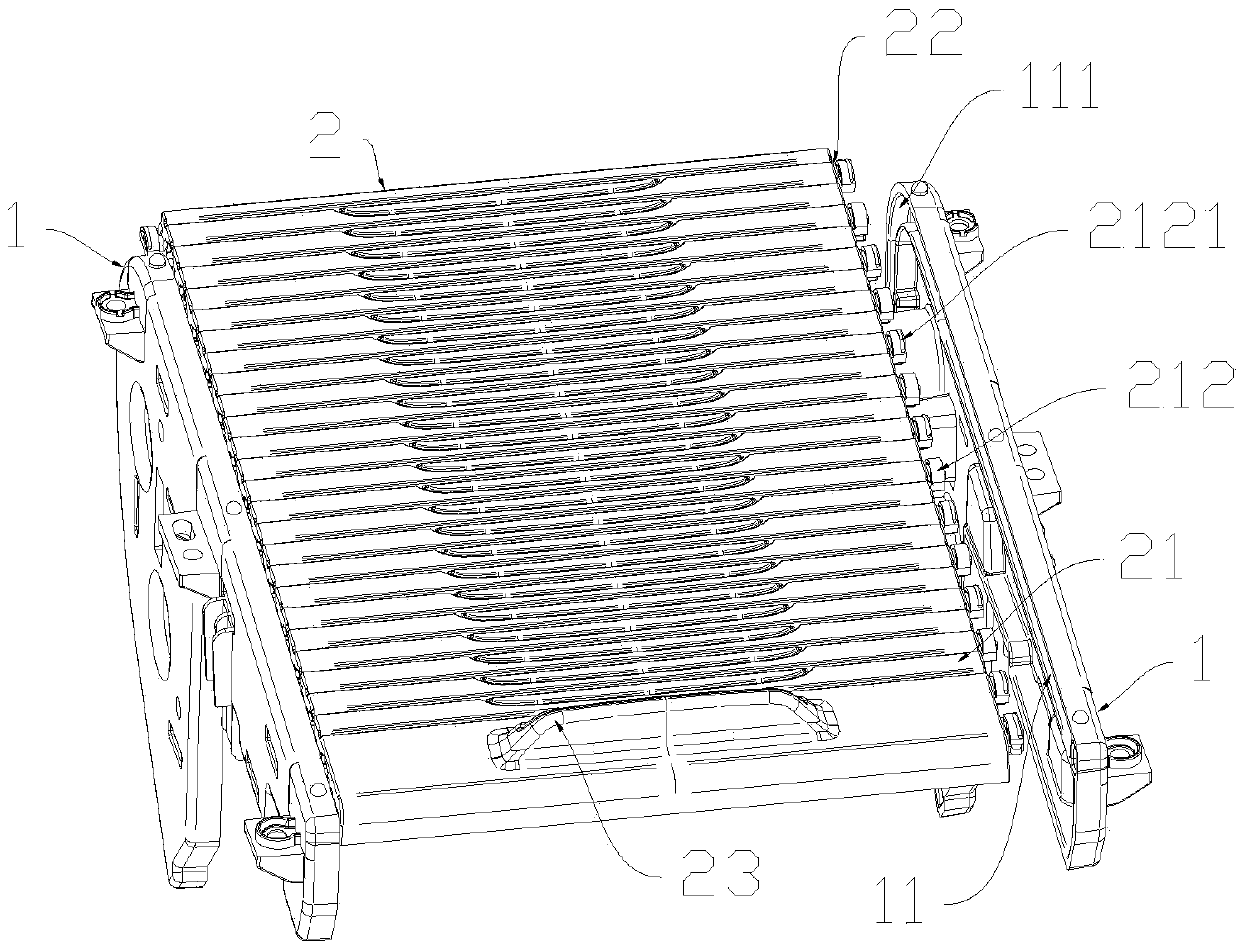

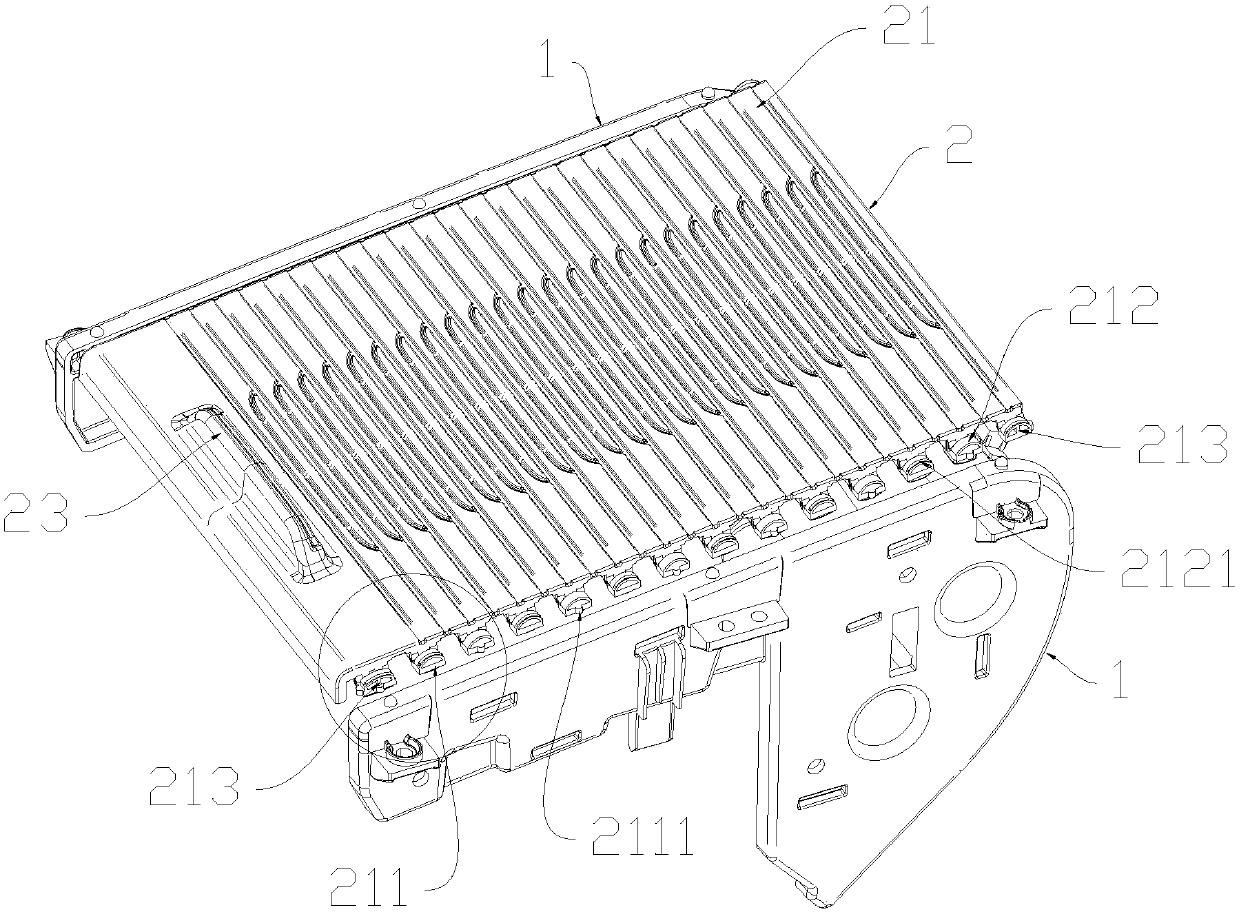

[0031] This embodiment is an improvement made on the basis of prior art, such as figure 2 , image 3 , Figure 4 As shown, in this embodiment, an arch bridge-shaped protrusion 212 made of rubber is provided on the upper surface of the slider 211 .

[0032] The protrusion 212 can greatly improve the smoothness of the rolling door body 2 passing through the bending arc 111 of the guide chute 11, effectively solving the problem that the existing rolling door is stuck or even stuck when passing through the bending arc 111 . without any negative effects.

[0033] When in use, when the slider 211 slides on the bending arc 111 of the guide chute 11, the upper surface of the guide chute 11 squeezes the protrusion 212, causing the protrusion 212 to undergo appropriate deformation, so that the blade 21 can pass through the bend smoothly. Bend arc 111 part. The arch bridge-shaped arc surface of the protrusion 212 has a small contact area with the upper surface of the guide chute 11...

Embodiment 2

[0041] This embodiment is another form of Embodiment 1. This embodiment includes a side plate 1 and a rolling door body 2; the side plate 1 is arranged on both sides of the storage box, and the opposite surface of the side plate 1 is provided with a guide chute 11. The tail end of the guide chute 11 is in the shape of a curved arc 111; the rolling door body 2 includes several blades 21, and the two ends of the blades 21 are provided with sliders 211 sliding in the guide chute 11; The rolling door also includes a roll layer 3 of rubber material, the inner surface of the roll layer 3 is provided with a blade slot 31, and the blade 21 is arranged in the blade slot 31; the two ends of the blade slot 31 extend out for wrapping The slider wrapping layer 33 covering the upper surface of the slider 211 is provided with an arch bridge-like protrusion 212 on the top of the slider wrapping layer 33 , and a gap 22 is provided between the back of the protrusion 212 and the end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com