Workpiece conveying device

A technology of conveying device and transportation device, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of waste of human resources, easy disorder of workpiece order, and affect processing quality, so as to avoid confusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

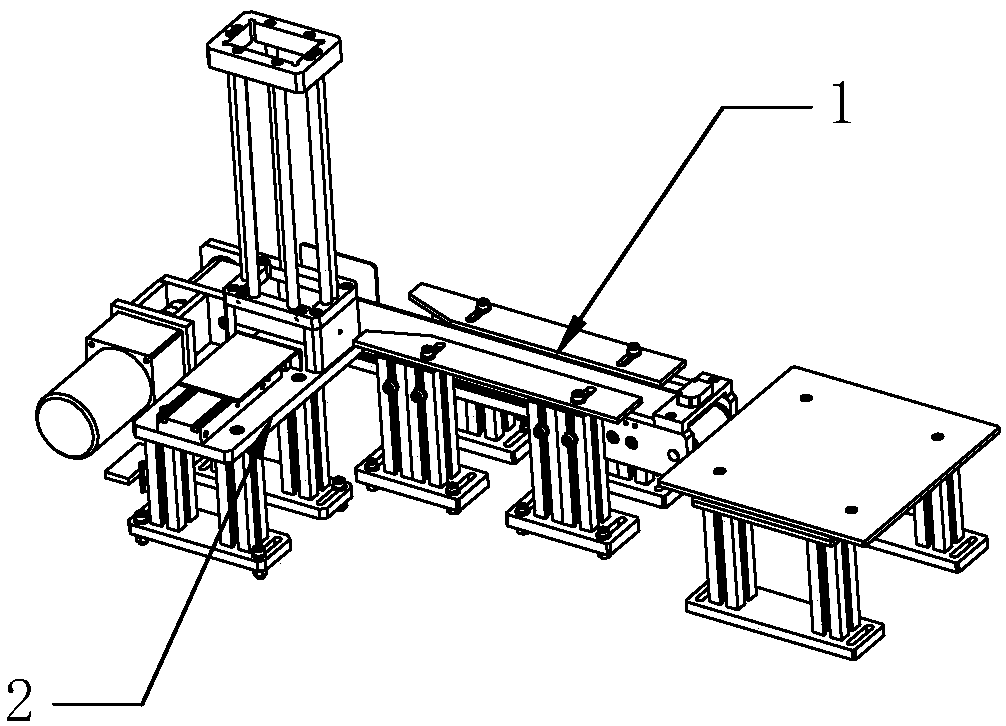

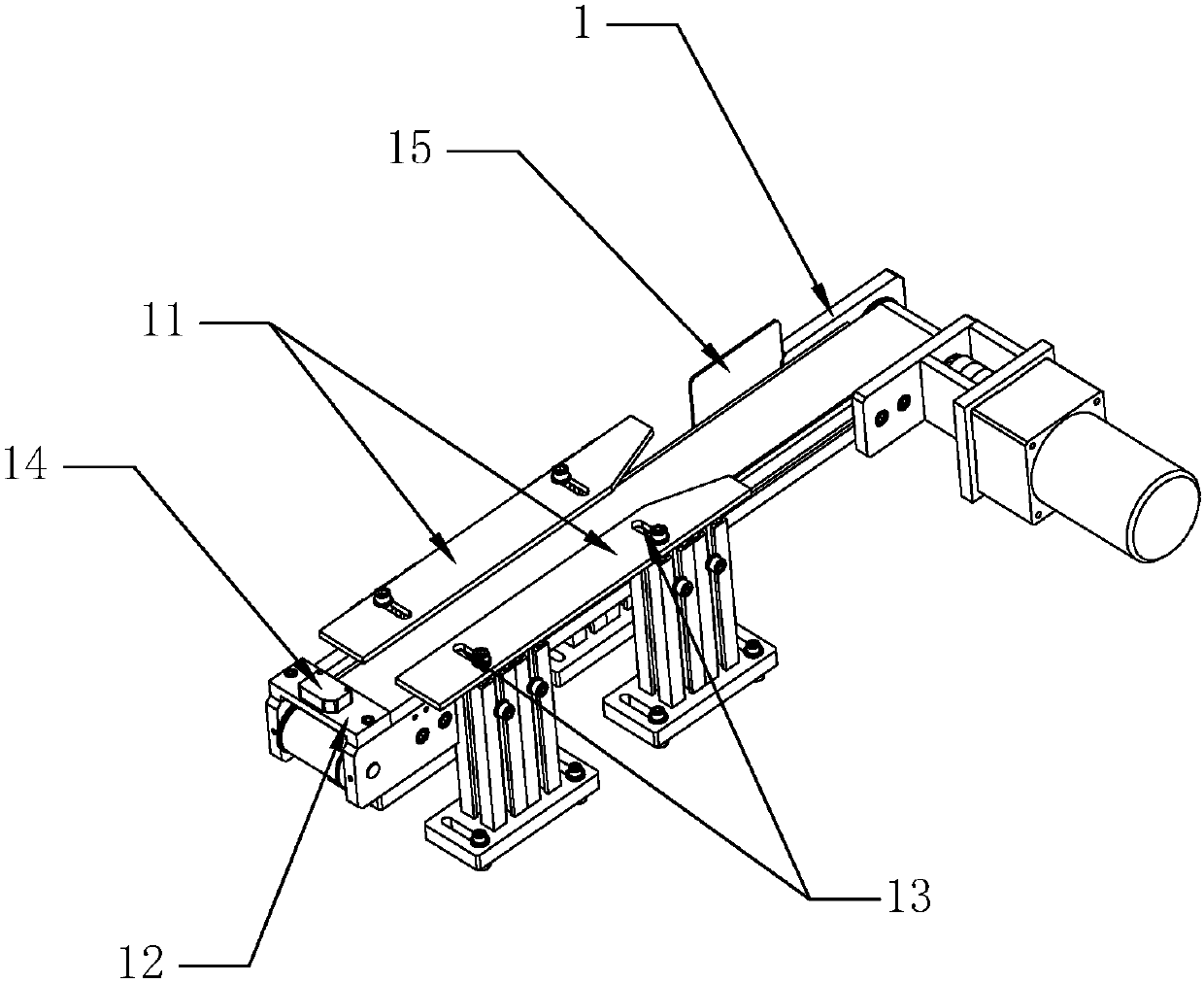

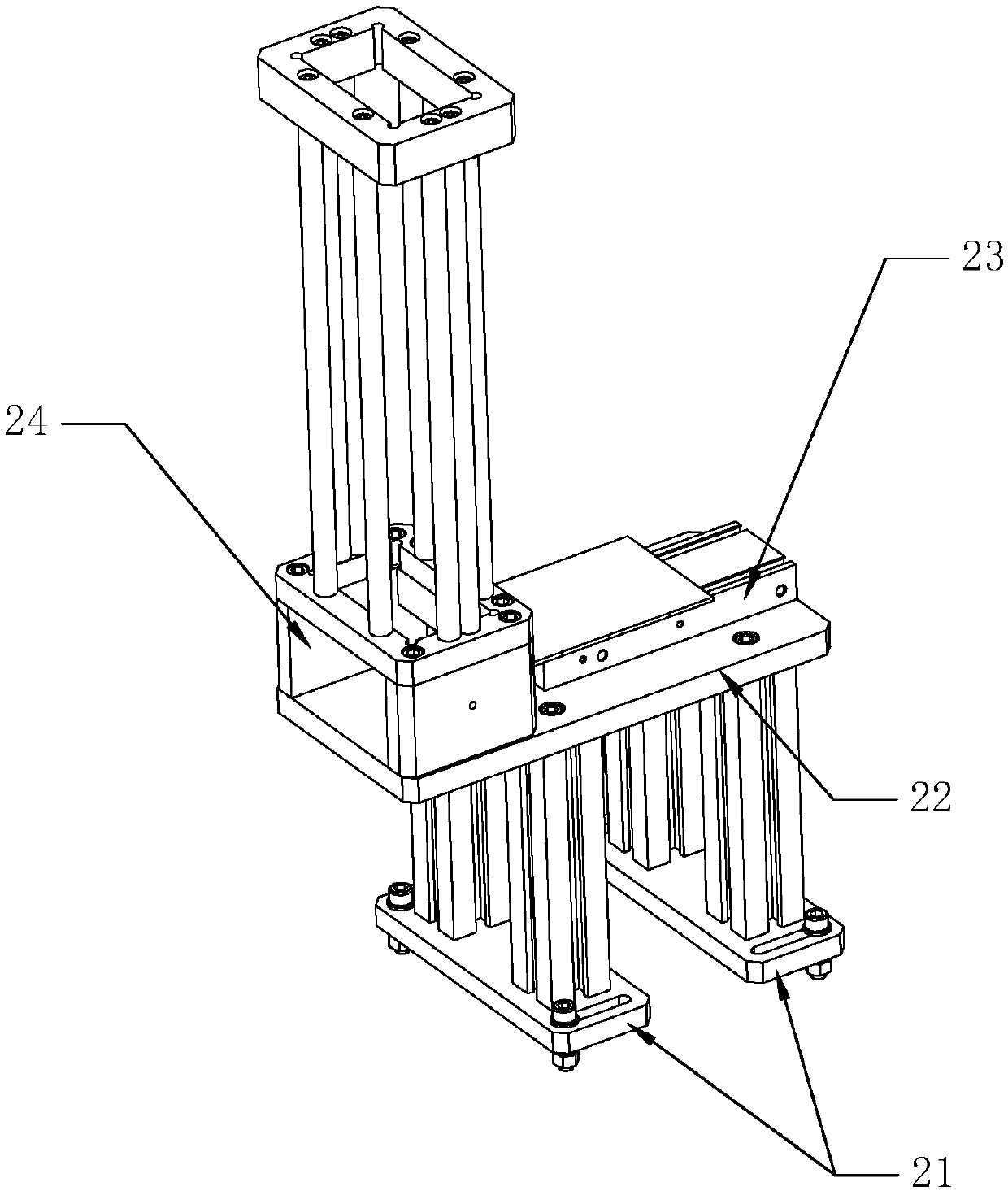

[0015] refer to Figure 1 to Figure 3 , a workpiece conveying device of the present invention, a workpiece conveying device, comprising a conveying device 1 for conveying a workpiece, and a feeding mechanism 2 for pushing a workpiece onto the conveying device 1, the feeding mechanism 2 is arranged on the One side of the transportation mechanism, the feeding mechanism 2 includes a base 21, a feeding platform 22 installed on the base 21 for pushing out workpieces, and a discharge channel 24 for placing workpieces. The discharge channel 24 is provided with infrared As for the detection device, opposite guide plates 11 are provided on both sides of the transport device 1 , a figure-eight opening is provided at the front end of the guide plate 11 , and a stopper 12 is provided at the end of the transport device.

[0016] During use, the workpiece enters from the discharge channel 24, so that the workpiece reaches the feeding platform 22, the infrared detection device detects the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com