Clamping and overturning device

A technology of turning device and turning mechanism, which is used in transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of large space occupation and complex structure, and achieve the effect of smooth movement and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

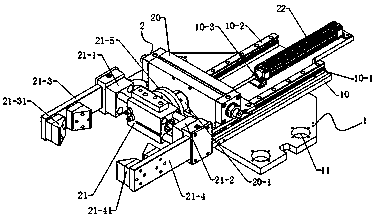

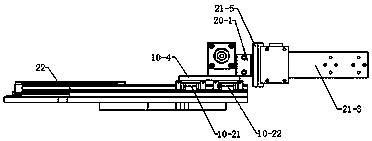

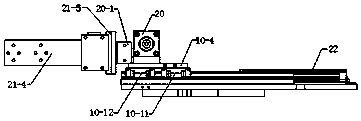

[0019] see Figure 1-4 , a clamping and turning device, including a bottom plate 1 and a turning mechanism 2, the bottom plate 1 is provided with a connecting plate 10, and the connecting plate 10 is fixedly connected with the bottom plate 1, and the connecting plate 10 is provided with a slide rail-10- 1 and slide rail two 10-2, said slide rail one 10-1 is provided with slide seat one 10-11 and slide seat two 10-12, said slide rail two 10-2 is provided with slide seat three 10- 21 and sliding seat four 10-22, described sliding seat one 10-11, sliding seat two 10-12, sliding seat three 10-21 and sliding seat four 10-22 upper surfaces are provided with support plate 10-4, and support One end of the plate 10-4 is fixedly connected with the upper surface of the first slide 10-11 and the second slide 10-12, and the other end of the support is fixedly connected with the upper surface of the third slide 10-21 and the fourth slide 10-22. 2 includes a motor 20, a linkage cylinder 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com