Light release force solvent-free organic silicon release agent as well as preparation method and application

A solvent-free, light peeling technology, applied in the direction of coating, film/sheet release liner, etc., can solve the problem that the ultra-light release force cannot be achieved, and meet the requirements of ultra-light peel force and release performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation of a solvent-free silicone release agent with light peeling force, the specific steps are as follows, parts by mass:

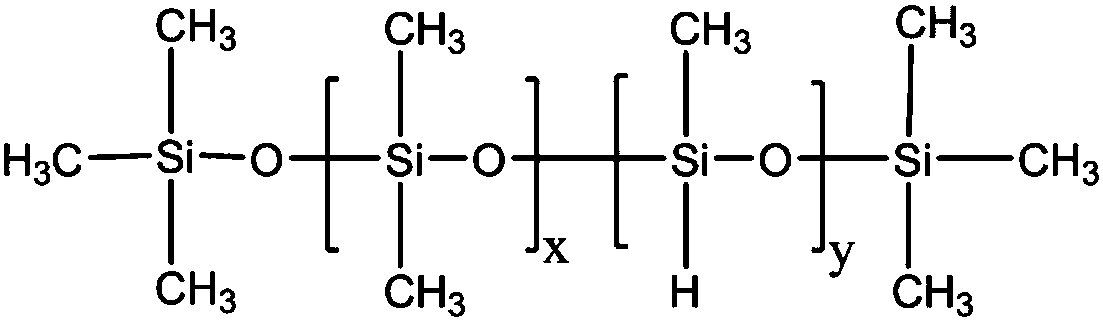

[0035] 1) According to the functional group ratio H / Vi=1.5, 100 parts of vinyl polysiloxane and 7 parts of hydrogen-containing polysiloxane;

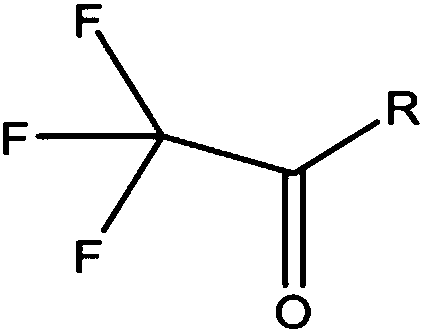

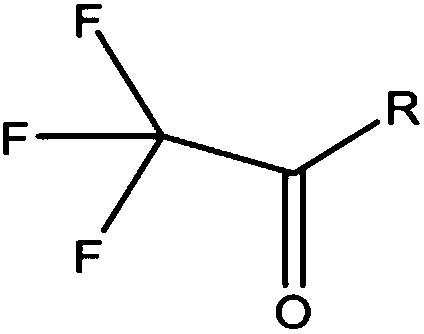

[0036] 2) 10 parts of anchoring agent (3-glycidyl etheroxypropyl triethoxysilane), 3 parts of fluorine-containing release force regulator (4-ethoxy-1,1,1-trifluoro-3- buten-2-one);

[0037] 3) 5 parts of platinum catalysts;

[0038] 4) Mix the proportions of steps 1) 2) 3) according to the above experimental steps to prepare a release agent.

[0039] 5) Coat the release agent in step 4) on the glassine paper with a coater, and cure at 150° C. for 30 seconds to obtain a release paper. The normal temperature peeling force of the obtained release paper is 3g / 25mm, and the aging peeling force is 3.5g / 25mm.

Embodiment 2

[0041] A preparation of a solvent-free silicone release agent with light peeling force, the specific steps are as follows, parts by mass:

[0042] 1) According to the functional group ratio H / Vi=1.5, 100 parts of vinyl polysiloxane and 7 parts of hydrogen-containing polysiloxane;

[0043] 2) 10 parts of anchoring agent (3-glycidyl etheroxypropyl triethoxysilane), 8 parts of fluorine-containing release force regulator (4-butoxy-1,1,1-trifluoro-3- buten-2-one);

[0044] 3) 5 parts by weight of platinum catalysts;

[0045] 4) Mix the proportions of steps 1) 2) 3) according to the above experimental steps to prepare a release agent.

[0046] 5) Coat the release agent in step 4) on the glassine paper with a coater, and cure at 150° C. for 30 seconds to obtain a release paper. The normal temperature peeling force of the obtained release paper is 1.3g / 25mm, and the aging peeling force is 1.7g / 25mm.

Embodiment 3

[0048] A preparation of a solvent-free silicone release agent with light peeling force, the specific steps are as follows, parts by mass:

[0049] 1) According to the functional group ratio H / Vi=2, 100 parts of vinyl polysiloxane and 9 parts of hydrogen-containing polysiloxane;

[0050] 2) 10 parts of anchoring agent (3-glycidyl etheroxypropyl triethoxysilane), 8 parts of fluorine-containing release force regulator (1,1,1-trifluoro-3-hepten-2-one );

[0051] 3) 5 parts by weight of platinum catalysts;

[0052] 4) Mix the proportions of steps 1) 2) 3) according to the above experimental steps to prepare a release agent.

[0053] 5) Coat the release agent in step 4) on the glassine paper with a coater, and cure at 150° C. for 30 seconds to obtain a release paper. The normal temperature peeling force of the obtained release paper is 1.8g / 25mm, and the aging peeling force is 2.4g / 25mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com