Position locking structure for mechanical installation

A locking and mechanical technology, applied in mechanical equipment, fixtures and other directions, can solve the problems of increasing structural weight and external dimensions, limitations of applicability and practicability, inconvenient disassembly and assembly, and achieves good practicability and good use stability. , the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

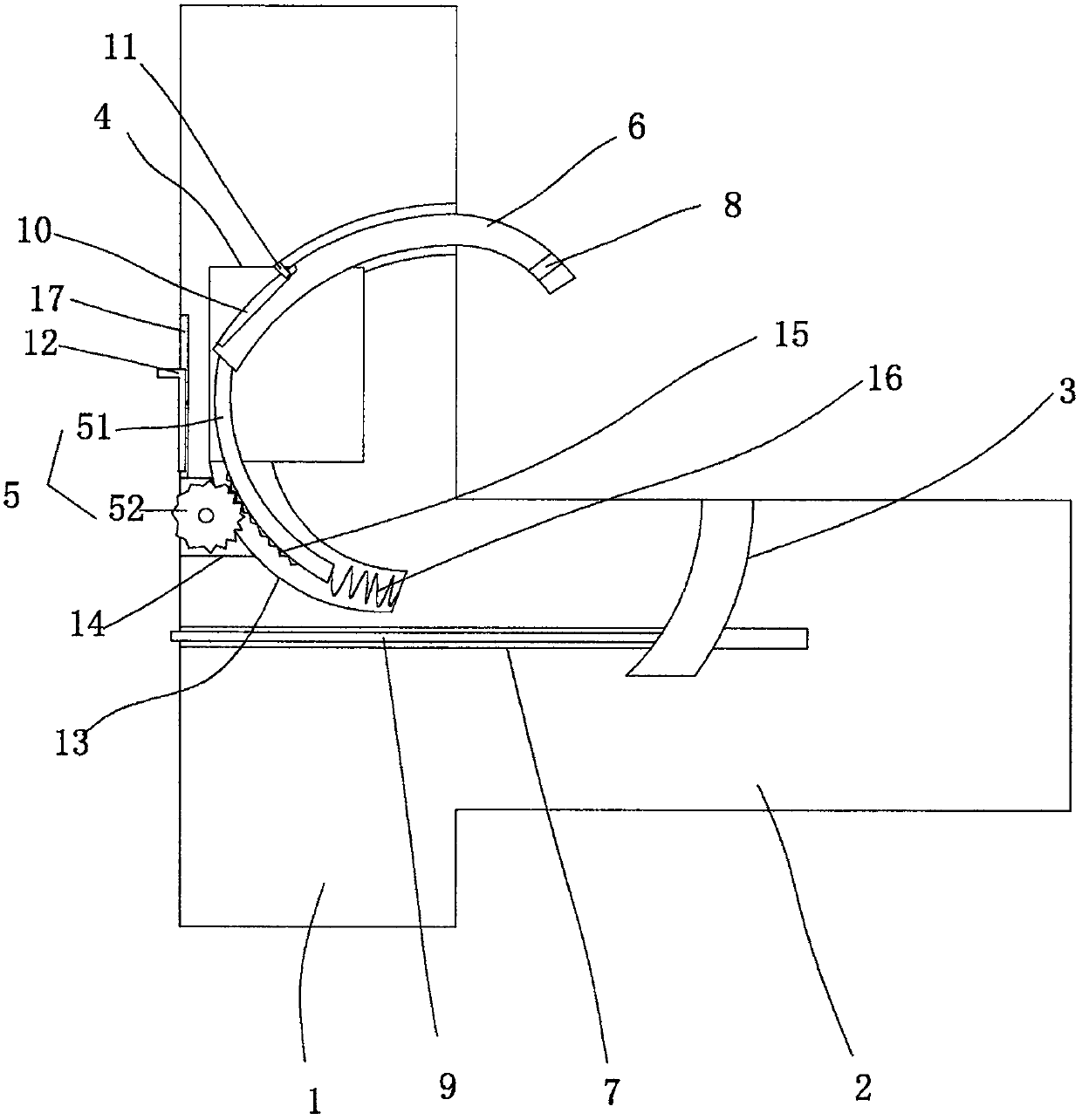

[0014] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0015] See figure 1 , a locking structure for mechanical installation, including a locking seat 1, on which a transverse bearing protrusion 2 is integrally formed, at the connection between the locking seat 1 and the transverse bearing protrusion 2 An arc-shaped locking hole 3 is provided, a locking cavity 4 is arranged in the locking seat 1, a lifting structure 5 is fixed in the locking cavity 4, and a lifting structure 5 is fixed in the locking hole 3. An arc-shaped locking rod 6, one end of which is fixed on the lifting structure 5, and an insertion slot 7 is arranged between the locking seat 1 and the lateral bearing protrusion 2, An insertion card 9 is arranged in the insertion groove, and the insertion groove extends to the arc-shaped locking hole of the lateral bearing protrusion, and the end of the arc-shaped locking rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com