Rectification assembly suitable for multi-load missile and missile

A multi-load and payload technology, applied in self-propelled projectiles, projectiles, offensive equipment, etc., can solve the problems of inability to meet the flexible configuration of multi-load, limit the lightweight and reliability of missiles, and the physical constraints of the load shape envelope. Achieve the effect of avoiding additional mass, meeting lightweight requirements, and eliminating physical constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

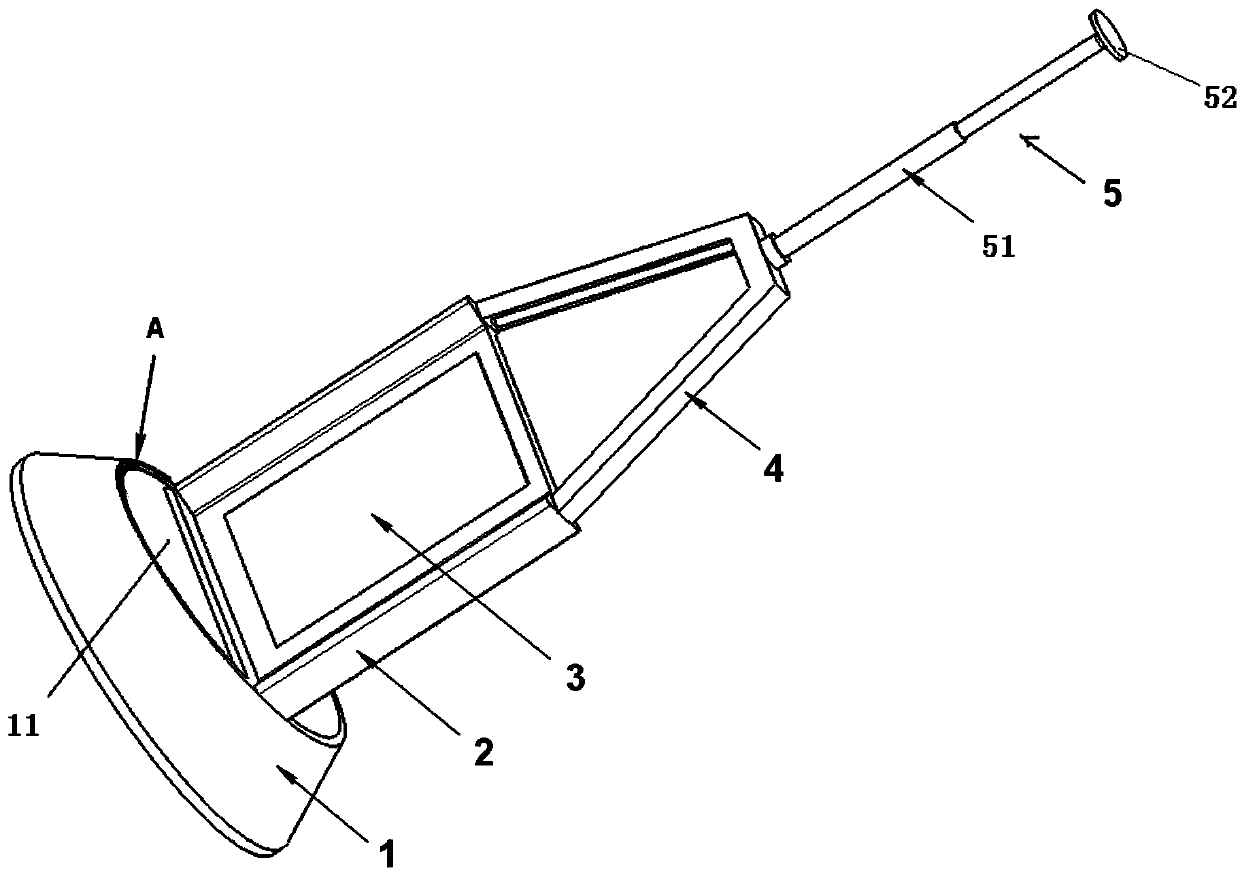

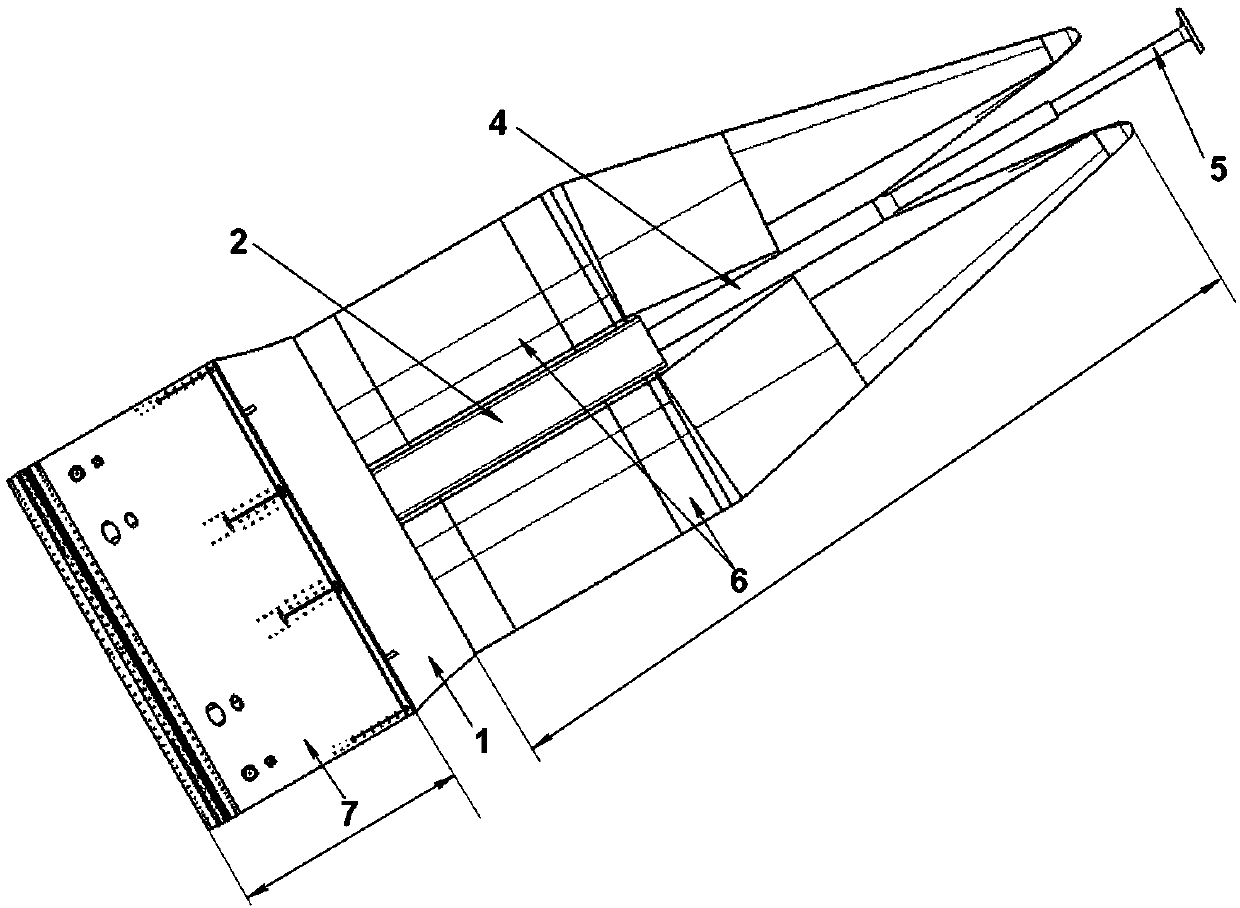

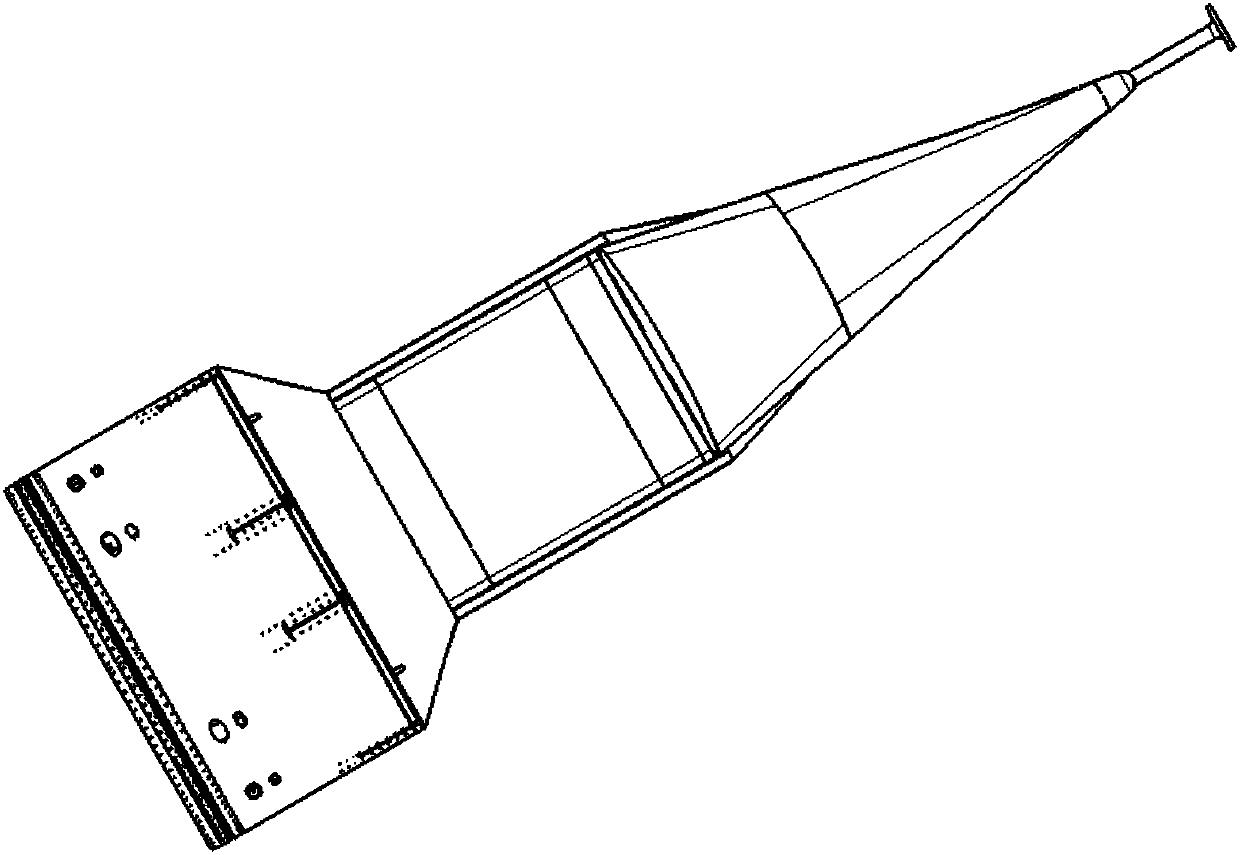

[0047] This embodiment provides a rectifying assembly of a dual-load missile, such as figure 2 As shown, the rectification assembly includes a load bracket 1, a cushion block 3, a support frame 2, a rectification rod bracket 4 and a rectification rod 5; as figure 1 As shown, the load bracket 1 is a hollow structure with a variable cross-section, the first end of the load bracket 1 is circular, and its outer diameter is consistent with the outer diameter of the missile cabin. The second end of the load bracket 1 is provided with two mounting holes 11, and other The position is closed; the two loads 6 are symmetrically installed on the load bracket 1 through two mounting holes 11 respectively, and the flatness of the mounting surface of the load 6 and the load bracket 1 is 0.1; The middle position of the second end face of the bracket 1 makes the two loads 6 separate on both sides; the rectifying rod bracket 4 is connected with the second end of the load bracket 1 through the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com