Full-automatic plastic bag labeller

A technology for plastic bags and labeling machines, which is applied in labeling machines, labeling, labels, etc. It can solve problems such as inseparability and missed labeling of objects, and achieve the goal of improving labeling quality, labeling efficiency, and labeling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

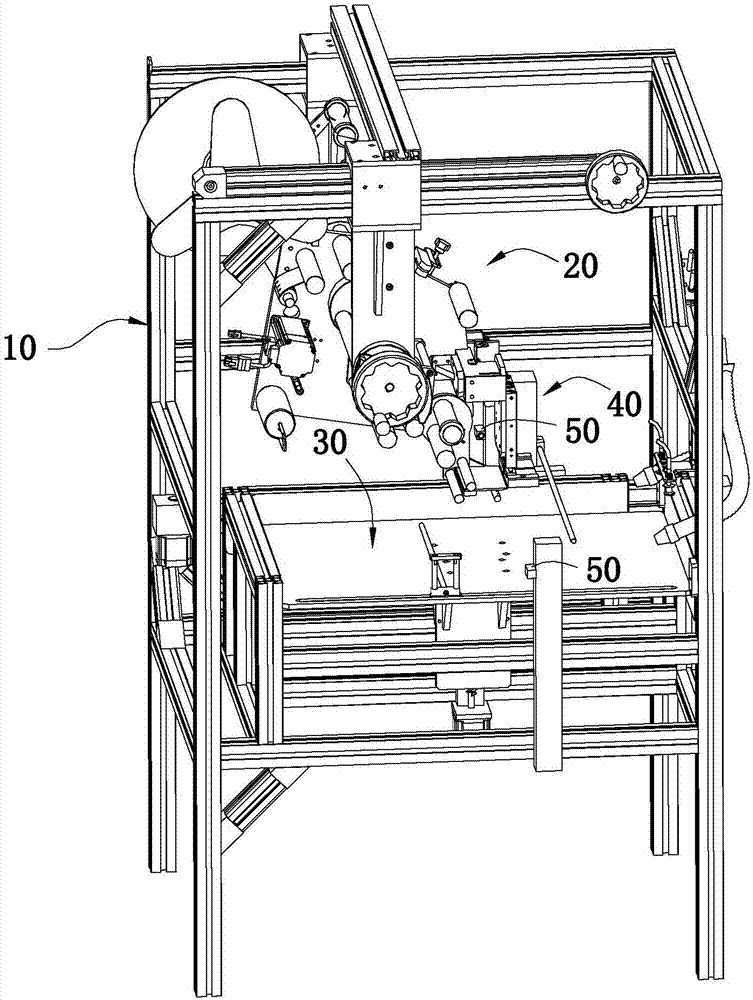

[0041] refer to figure 1 , a fully automatic plastic bag labeling machine, comprising a frame 10, a stacking mechanism 30 located on the frame 10, a labeling mechanism 20 and a turning mechanism 40, the labeling mechanism 20 is maintained on the frame 10 with the stacking mechanism 30 In the overhead state, the two sides of the stacking mechanism 30 are also provided with shooting switches 50 .

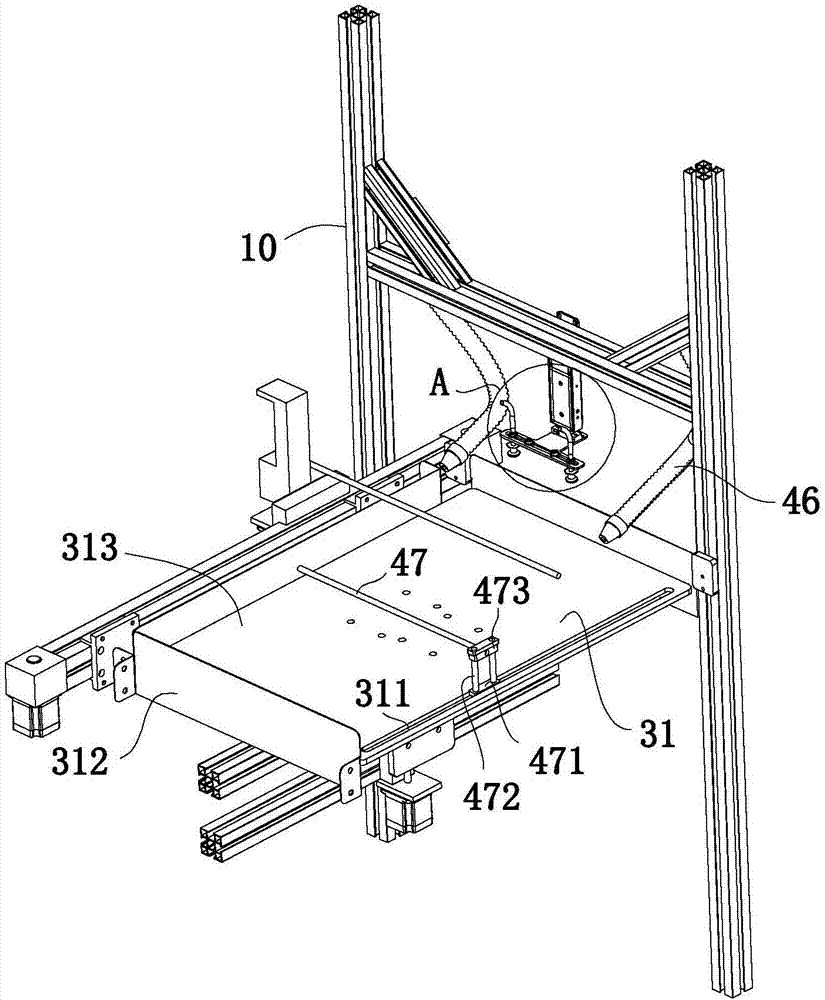

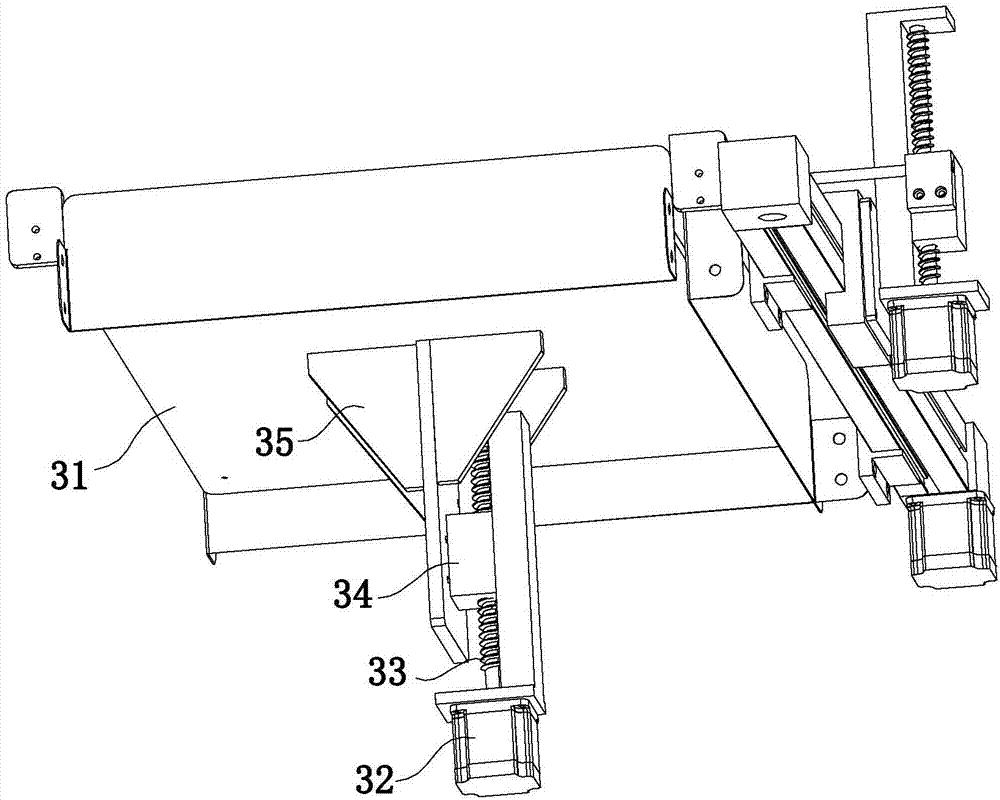

[0042] common reference figure 2 and image 3 The stacking mechanism 30 includes a stacking platform 31 and a second lifting module connected to the bottom of the stacking platform 31 . The side of the stacking platform 31 is provided with three baffles 312 fixed on the frame 10, and the three baffles 312 and the upper surface of the stacking platform 31 form a stacking groove 313, which is used to place the labels to be labeled. plastic bag.

[0043] The secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com