Machining device used for rectification device

A technology for processing devices and rectifier devices, which is applied in the manufacture of electric solid state devices, semiconductor devices, and semiconductor/solid state devices, etc., can solve the problems of increasing turnover tools, increasing labor costs, increasing the risk of product damage, and reducing turnover tools, The effect of reducing the turnover process and improving the product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

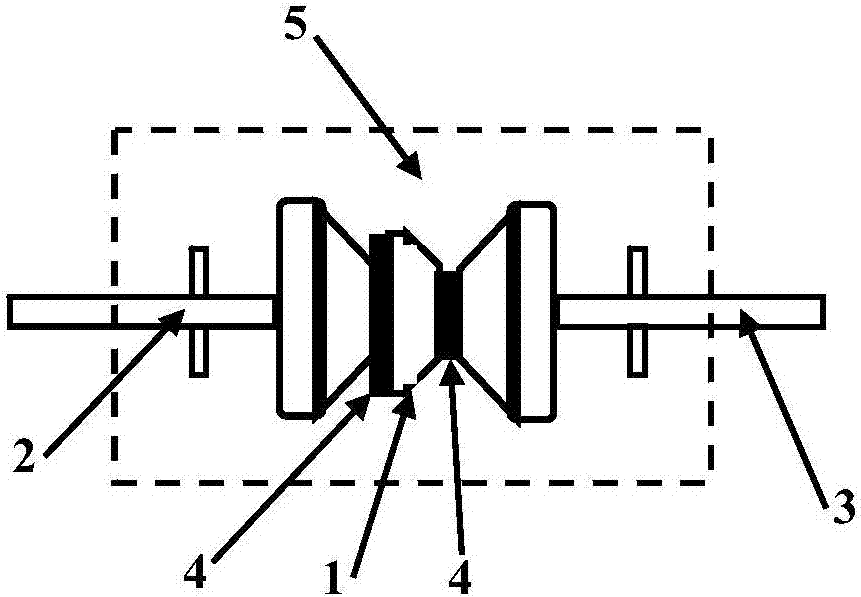

[0019] Embodiment 1: A processing device for a rectifier device, the axial diode includes a diode chip 1, a first copper lead 2, and a second copper lead 3, and one end of the first copper lead 2 is connected to the The N pole surface of the diode chip 1, the other end of the first copper lead 2 is used as the axial diode input end; one end of the second copper lead 3 is connected to the P pole surface of the diode chip 1 through solder 4 , the other end of the second copper lead 3 is used as the input end of the axial type diode, and one end of the diode chip 1, the first copper lead 2 and the second copper lead 3 in contact with the diode chip is covered by an epoxy body 5;

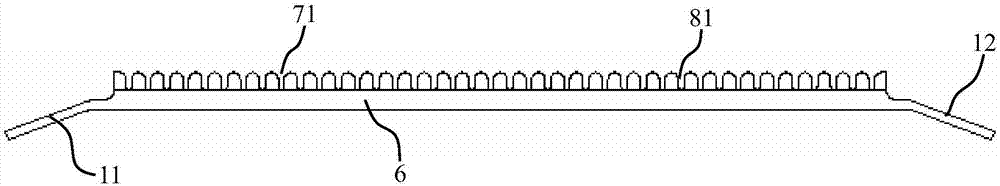

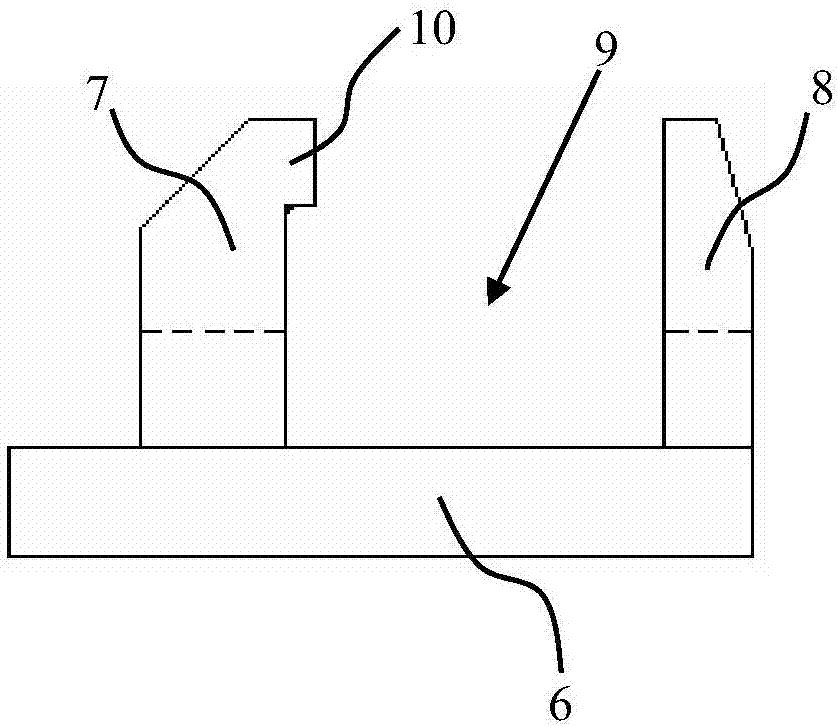

[0020] The turnover device includes a strip substrate 6, several comb teeth 7 and several orientation teeth 8, and several comb teeth 7 are located in the middle of the strip substrate 6 and arranged in a line along its length direction. The orientation teeth 8 are located on one side of the strip subst...

Embodiment 2

[0023] Embodiment 2: A processing device for a rectifier device, the axial diode includes a diode chip 1, a first copper lead 2, and a second copper lead 3, and one end of the first copper lead 2 is connected to the The N pole surface of the diode chip 1, the other end of the first copper lead 2 is used as the axial diode input end; one end of the second copper lead 3 is connected to the P pole surface of the diode chip 1 through solder 4 , the other end of the second copper lead 3 is used as the input end of the axial type diode, and one end of the diode chip 1, the first copper lead 2 and the second copper lead 3 in contact with the diode chip is covered by an epoxy body 5;

[0024] The turnover device includes a strip substrate 6, several comb teeth 7 and several orientation teeth 8, and several comb teeth 7 are located in the middle of the strip substrate 6 and arranged in a line along its length direction. The orientation teeth 8 are located on one side of the strip subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com