Diode device circulation device capable of facilitating loading

一种二极管、器件的技术,应用在二极管器件周转装置领域,能够解决增加周转工具、增加人工成本、增加产品损伤的风险等问题,达到减少周转工具、减少的工序、提高产品良率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

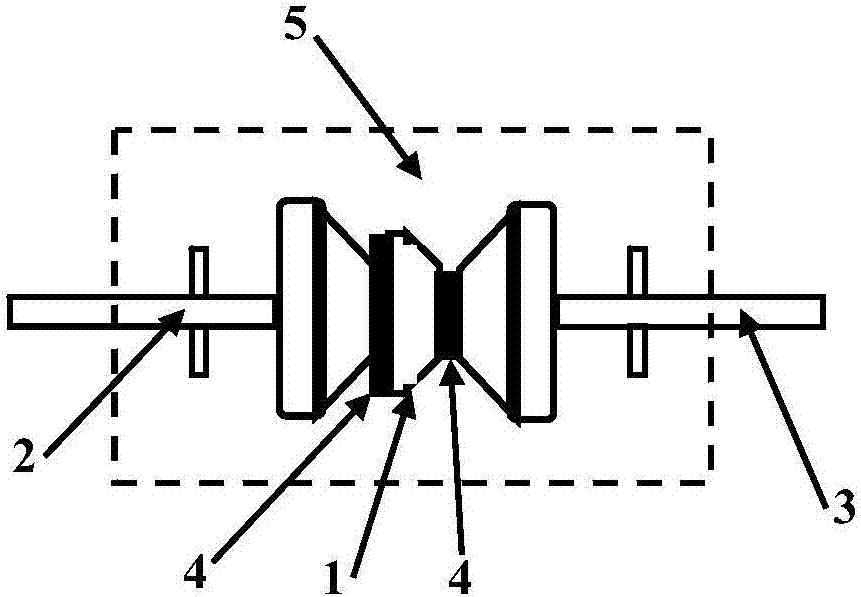

[0019] Embodiment: A diode device turnover device convenient for loading. The axial diode includes a diode chip 1, a first copper lead 2, a second copper lead 3, and one end of the first copper lead 2 is connected by solder 4 To the N pole face of the diode chip 1, the other end of the first copper lead 2 serves as the input end of the axial diode; one end of the second copper lead 3 is connected to the P of the diode chip 1 through solder 4 On the pole face, the other end of the second copper lead 3 serves as the input end of the axial diode, and the end of the diode chip 1, the first copper lead 2 and the second copper lead 3 contacting the diode chip is covered by epoxy body 5. ;

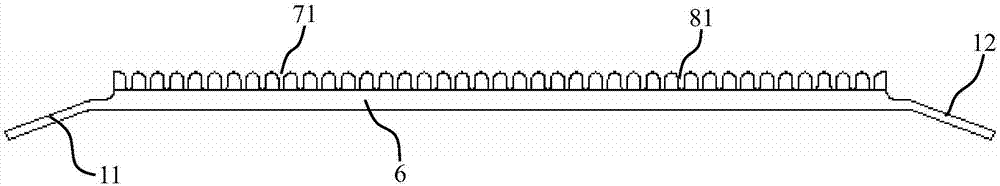

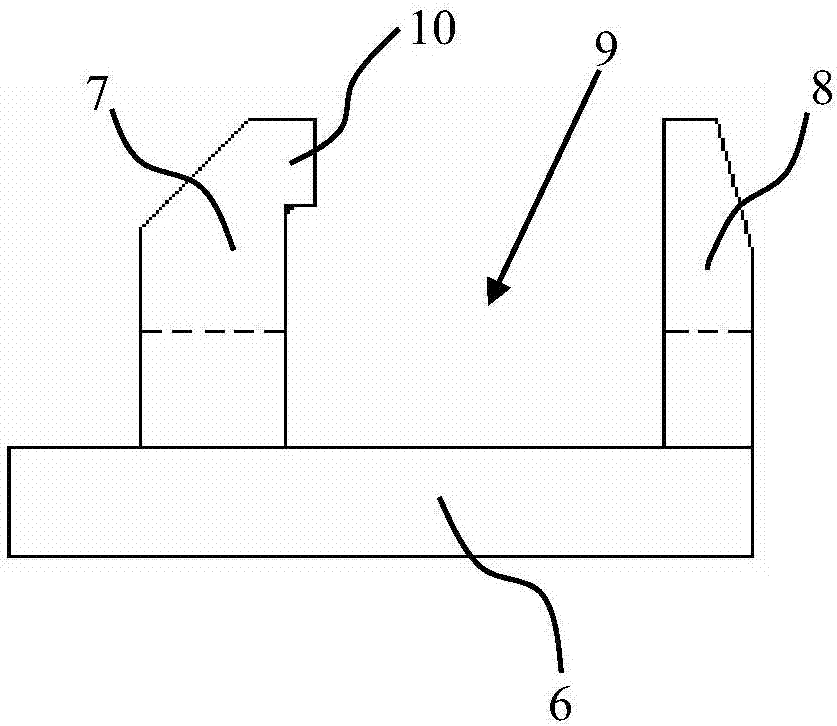

[0020] The turnover device includes a strip substrate 6, a number of comb teeth 7 and a number of directional teeth 8. The plurality of comb teeth 7 are located in the middle of the strip substrate 6 and are arranged in a line along its length. The directional teeth 8 are located on one side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com