Method and structure for plugging glue inlet hole and glue channel of mould

A technology of flow glue channel and glue inlet hole, which is applied in the field of plugging the glue inlet hole and flow glue channel of the mold, can solve the problems of affecting the surface quality of the joint area, affecting the product quality, slow heat dissipation of the sharp edge, etc., and shortening the process turnover. The effect of shortening time, fitter repair time, and reducing process turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a limitation to the present invention.

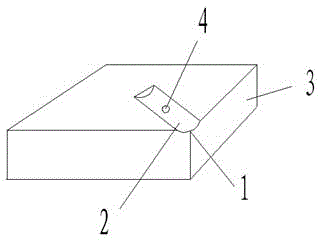

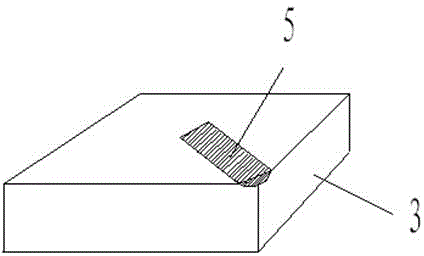

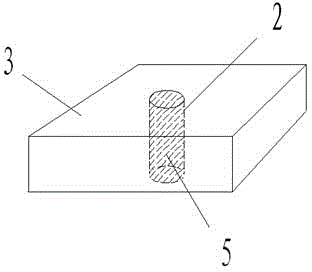

[0014] Embodiment of the present invention: a method for blocking the glue inlet and the glue flow path of the mold. When the glue inlet and the glue flow path of the mold are blocked, the fitter drills the material nest on the glue flow path in advance, and then Then press the rivet into the glue inlet and the glue flow channel, and the fitter uses tools to beat and squeeze the rivet, so that the rivet can be filled and firmly attached to the glue inlet and the glue flow channel, and then the glue inlet and the glue flow channel are fixed. The end and the surface of the glue flow channel are smoothed to ensure that the filling part and the surface of the mold are smooth and flat, and the filling of the glue inlet hole and the glue flow path can be completed.

[0015] The rivets are aluminum ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com