Nuclear power plant steam generator water chamber inner surface video inspection device

A technology for steam generators and inspection devices, which is applied to measuring devices, instruments, scientific instruments, etc., and can solve problems such as economic losses, scanning equipment collisions, and clear viewing angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

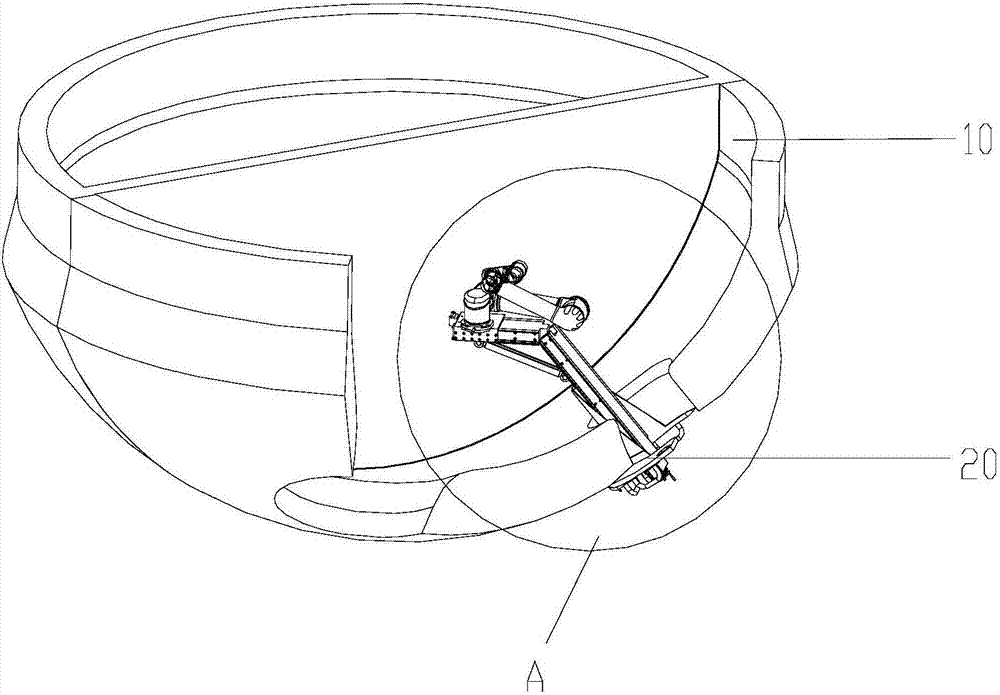

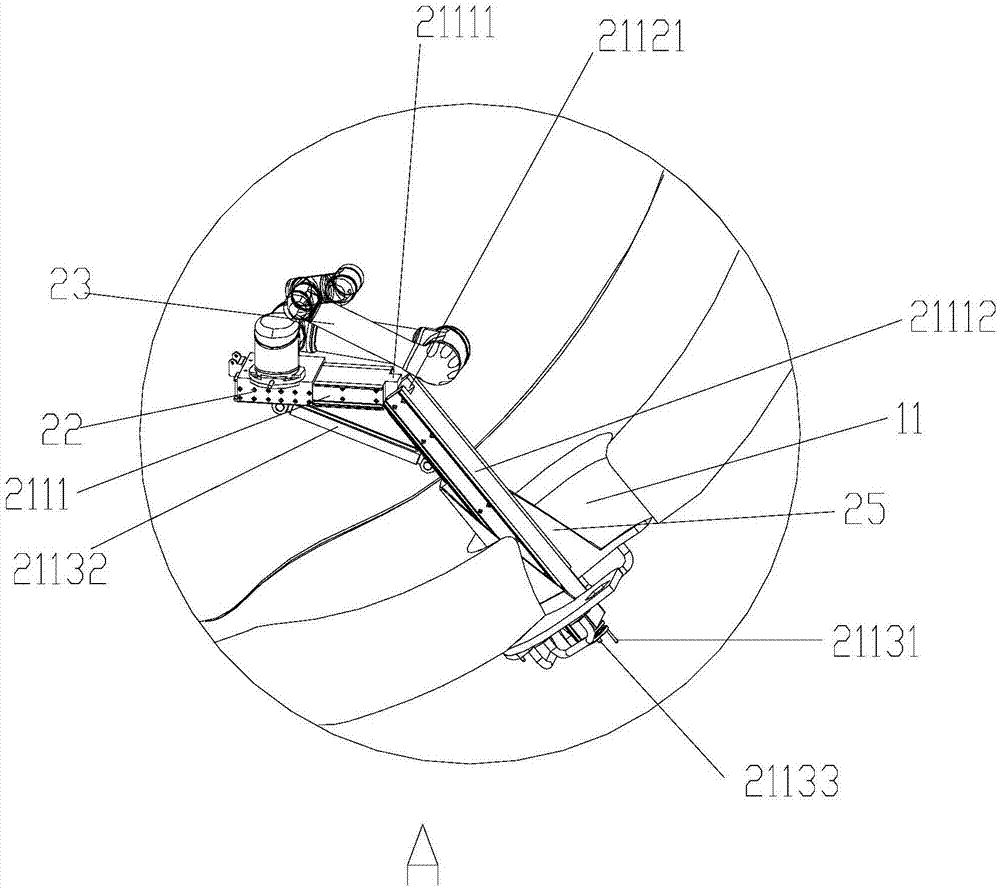

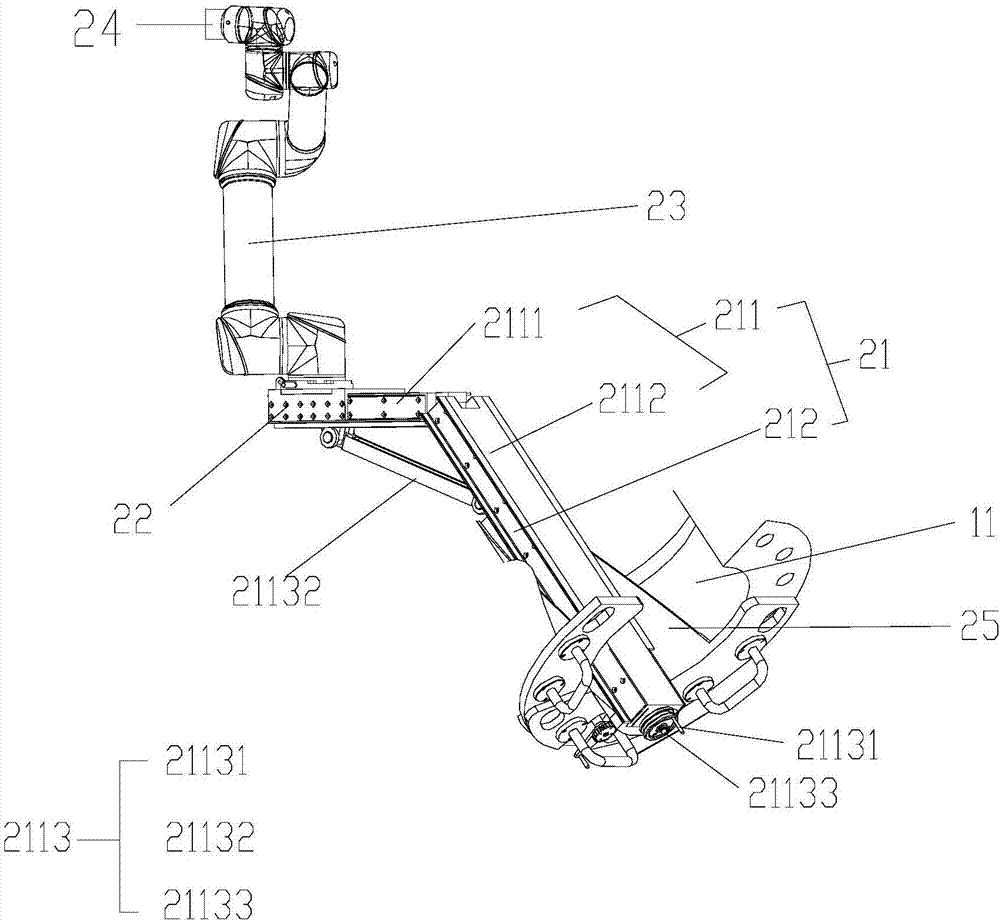

[0040] Such as Figure 1-5 As shown, this embodiment provides a video inspection device for the surface of the steam generator water chamber of a nuclear power plant, which is used to detect the contact surface of the surfacing layer in the steam generator water chamber 10 of the nuclear power plant. The video inspection device 20 consists of the The manhole 11 part of the steam generator water chamber 10 extends into the inside of the steam generator water chamber 10, which includes a positioning support frame 21, a slide block 22 arranged on the positioning support frame 21, and the slide block 22 A manipulator fixedly connected, a camera 24 arranged at the end of the manipulator, a manhole flange 25 and a locking mechanism for locking the slider 22 on the top of the positioning support frame 21 (not shown, the locking mechanism can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com