Rapid broaching device for angular milling head

A tool device and milling head technology, applied in the field of CNC machining technology and equipment, can solve the problems of poor consistency of tensioning force, product processing quality problems, shortened service life of tool holders, etc. inefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

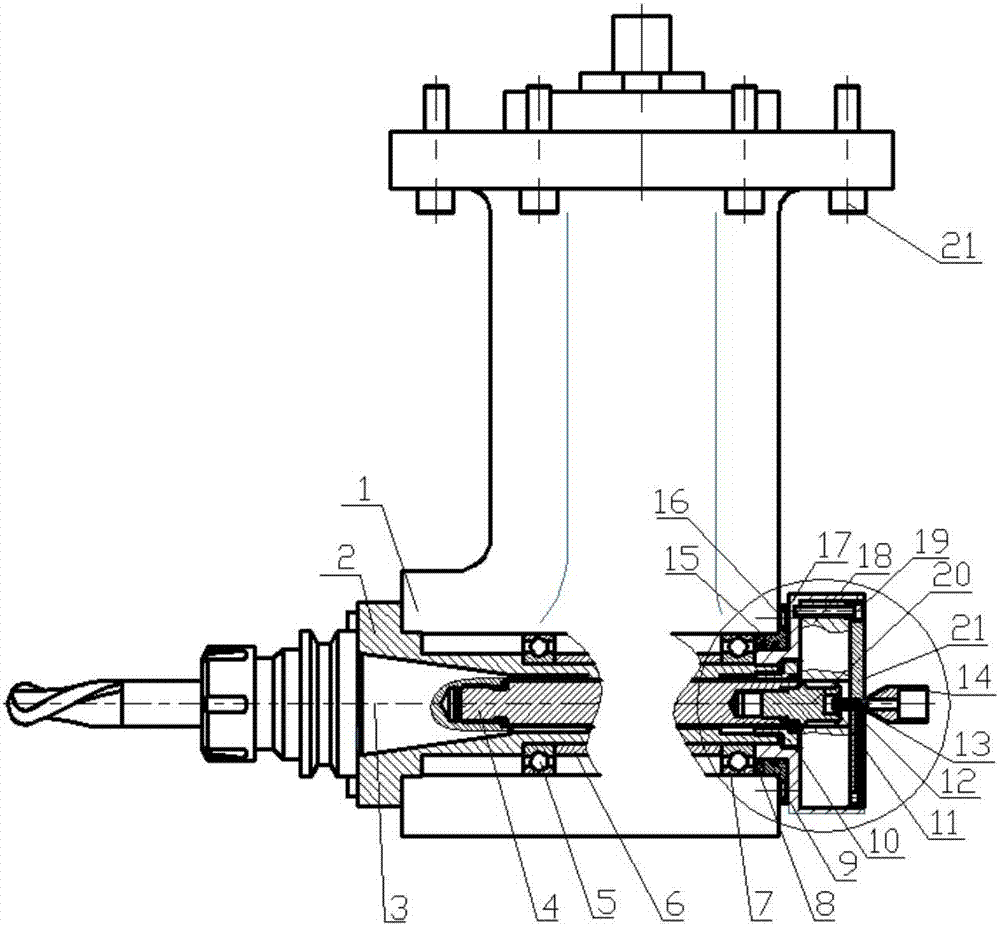

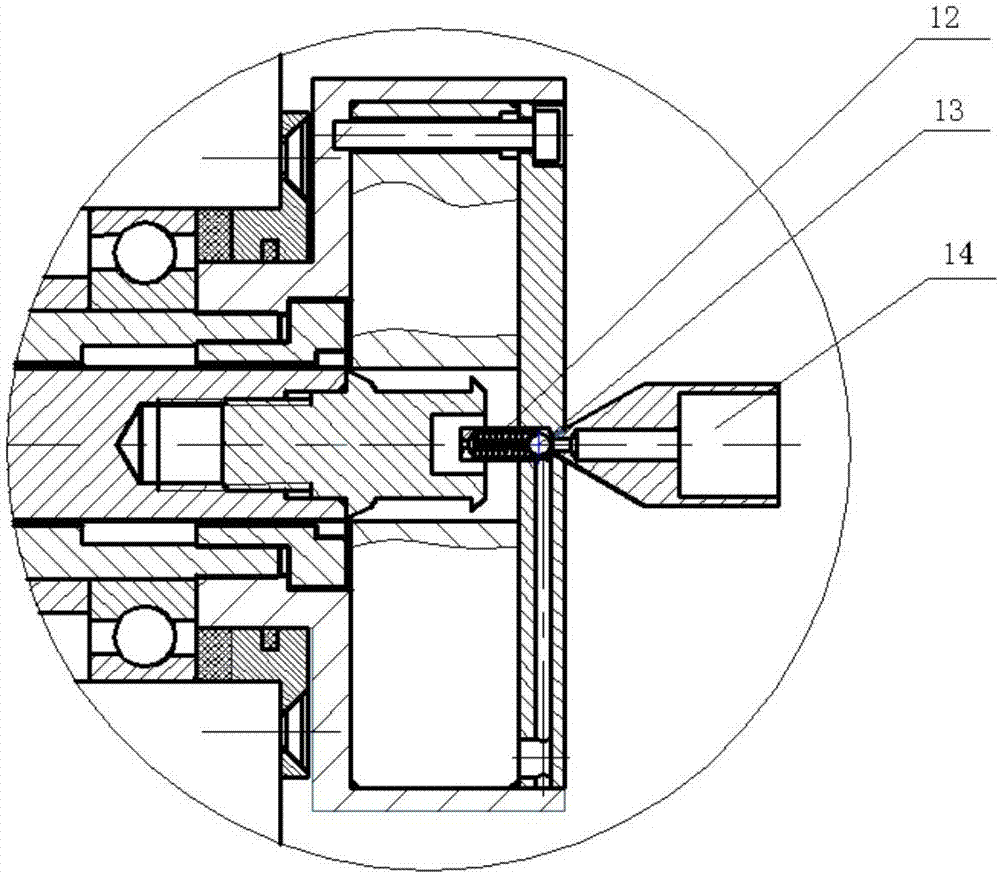

[0036] The angle milling head 1 is connected to the end face of the main shaft of the boring and milling machine through a plurality of bolts evenly distributed in the circumferential direction, and the output shaft 2 of the angle milling head can rotate at the center of the angle milling head 1 .

[0037] The milling cutter handle 3 and the output shaft 2 of the angle milling head are matched by a tapered surface, the front end of the tool pull rod 4 is threaded with the rear end of the handle 3, and the front end of the pull stud 20 is threaded with the rear end of the pull rod.

[0038] The fixed flange 9 is connected to the rear end of the angle milling head 1 through 4 countersunk screws 16, the inner thread of the rotating flange 17 is connected to the external thread of the output shaft 2 of the angle milling head, and the outer thread of the locking nut 10 is connected to the output shaft of the angle milling head 2 Internal thread connection, the internal thread of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com