Direct-cooling closed heat dissipation chassis

A chassis, direct cooling technology, applied in the direction of cooling/ventilation/heating transformation, modification using gaseous coolant, electrical components, etc., can solve the problem of low heat dissipation efficiency and achieve the effect of improving heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

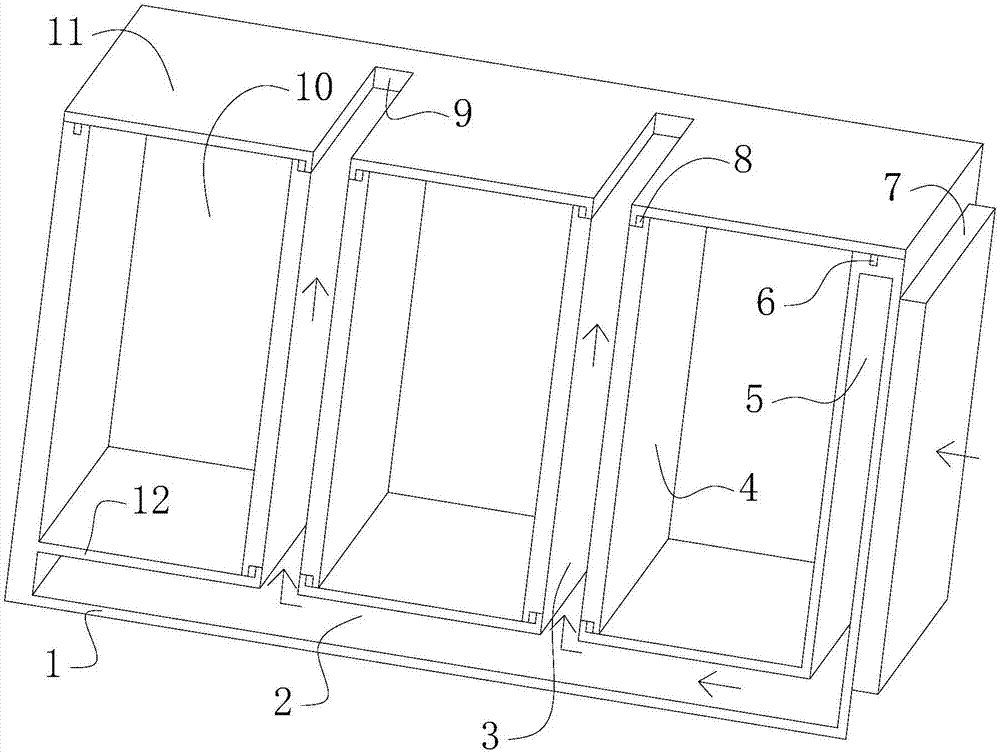

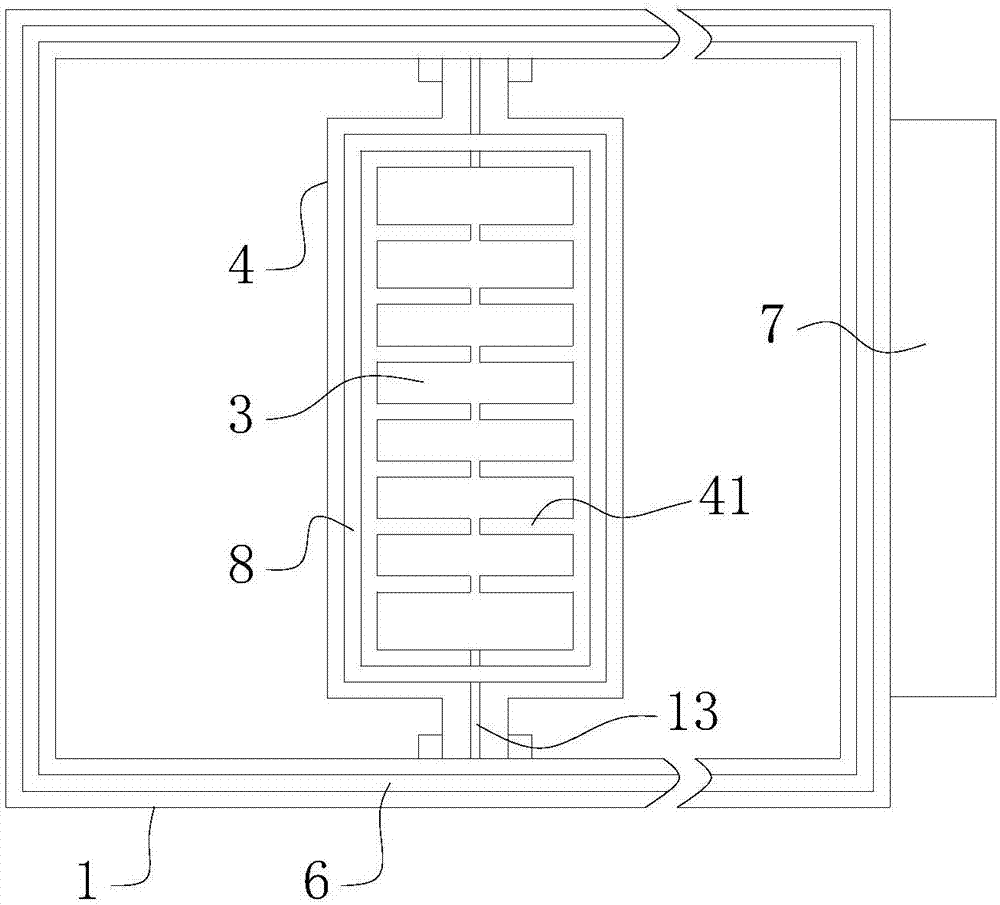

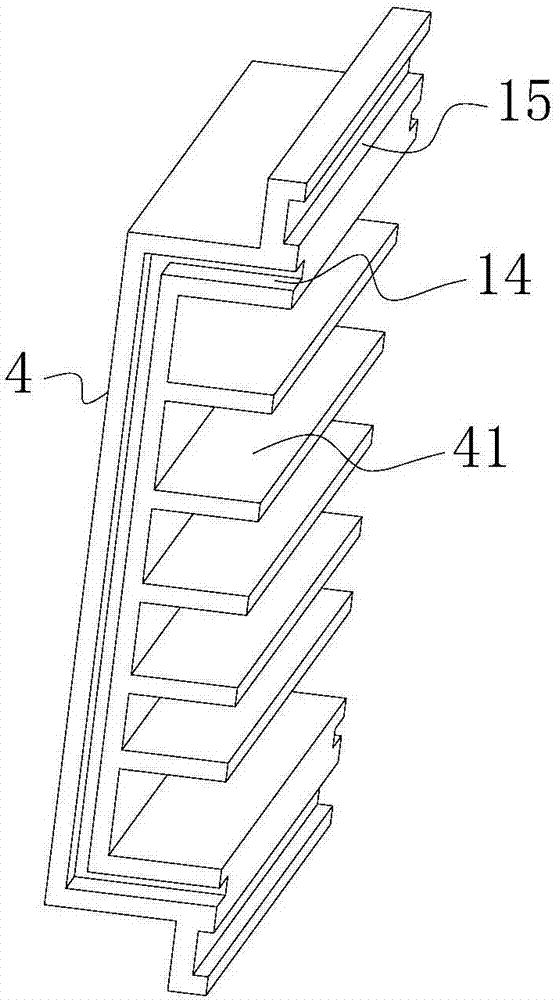

[0023] Such as Figure 1-3 As shown, the direct cooling airtight cooling cabinet provided in this embodiment includes a box body 1, a partition plate 12, a cover plate 11 and at least two cold plates 4, and the partition plate 12 divides the inner cavity of the box body 1 into an isolated cavity and a In the air inlet chamber 2, two adjacent cold plates 4 are connected back to back to form a cold plate group. A heat dissipation channel 3 is arranged between the two cold plates 4 of the cold plate group. The cold plate 4 is installed in the isolation chamber of the box body 1. The cold plate group divides the isolation chamber of the box body 1 into at least two device chambers 10, the cover plate 1 is installed on the box body to seal the device chamber 10, and the box body 1 is provided with an air inlet to connect to the fan group 7 so that the fan Group 7 sends the wind into the air inlet cavity 2, and the partition plate 12 is provided with an air duct opening connecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com