Heat dissipation structure used for surface of microelectronic chip

A heat dissipation structure and microelectronics technology, applied in the field of microelectronics, can solve the problems affecting the work and service life of chips, damage to microelectronic chips, etc., and achieve the effects of being conducive to rapid heat dissipation, fast air flow, and speeding up the condensation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

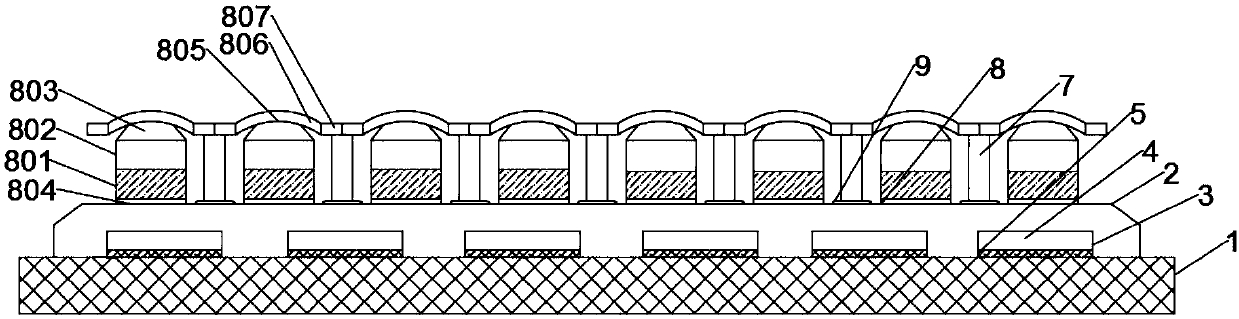

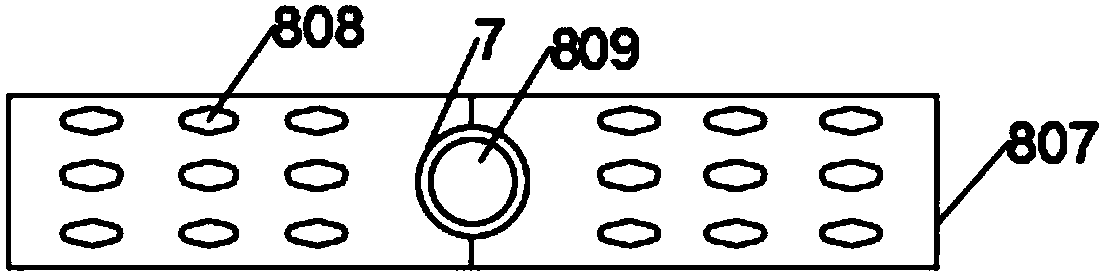

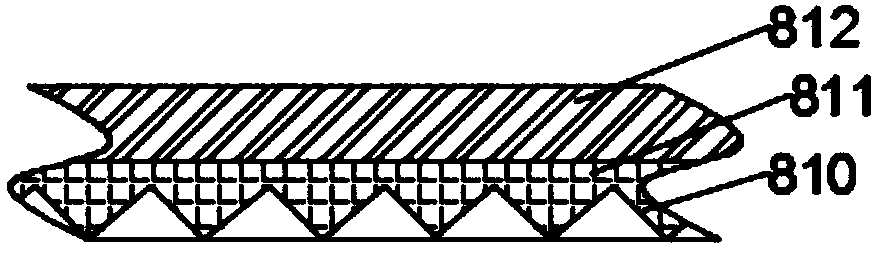

[0024] Such as Figure 1 to Figure 4 As shown, the present invention provides a heat dissipation structure for the surface of a microelectronic chip, including a chip substrate 1 and a heat conduction sheet 2, the heat conduction sheet 2 is arranged on the surface of the chip substrate 1, and the inside of the heat conduction sheet 2 is provided with several A perforation 3, the interior of the perforation 3 is provided with a heat-conducting silica gel pad 4, the heat-conducting silica gel pad 4 and the chip substrate 1 are connected together through a polytetrafluoroethylene insulating layer 5, and the heat-conducting silica gel pad 4 is used to make the heat-conducting sheet 2 and the chip substrate 1 connected together. The bonding between the chip substrates 1 is tighter, avoiding gaps, improving the heat dissipation effect and protecting the chip substrates;

[0025] The interior of the polytetrafluoroethylene insulating layer 5 adopts a porous structure, and the interio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com