Food processor with optimized air duct structure

A food processing machine and air duct technology, which is applied in the field of food processing, can solve the problems of unsatisfactory heat dissipation effect of the motor in the main machine, unable to quickly discharge the temperature of the main machine, and affect the service life of the product, so as to improve the service life, smooth the heat dissipation airflow, and ensure The effect of cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

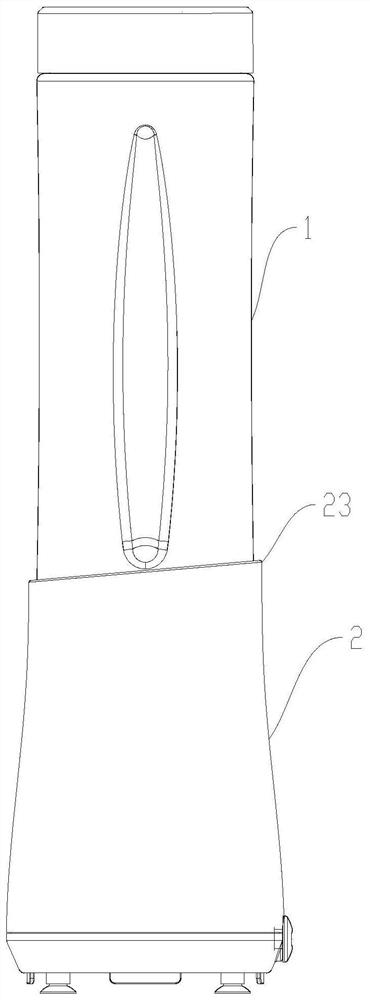

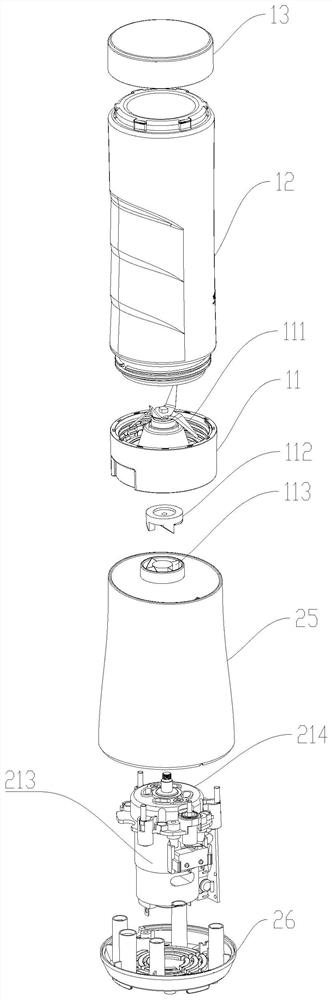

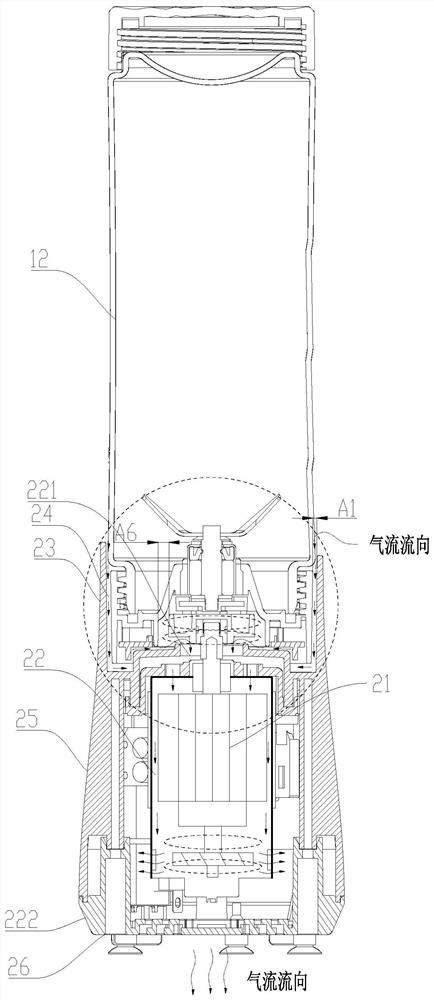

[0052] Such as Figure 1-Figure 4 As shown, a food processor with an optimized air duct structure disclosed in the present invention is an in-line food processor, including a main machine 2 and a processing cup assembly 1 installed on the main machine 2, and the processing cup assembly 1 can be connected with the The main machine 2 is detachably connected, and the processing cup assembly 1 and the main machine 2 can directly cooperate to realize the processing of food materials. The main engine 2 is provided with a motor assembly 21, the processing cup assembly 1 includes a knife seat assembly 11, a cup body 12 mounted on the knife seat assembly 11 and a cup cover 13 installed on the cup body, the knife seat assembly 11 includes a stirring member 111, The stirring member 111 is in transmission connection with the motor assembly 21 . In order to improve the heat dissipation efficiency of the motor assembly 21, a cooling air passage 22 is provided in the host machine 2. The coo...

Embodiment 2

[0066] Such as Figure 13-Figure 18 As shown, this embodiment is basically consistent with the technical solution disclosed in Embodiment 1, the only difference is that this embodiment is applied to other types of food processors (wall breaking machines, meat grinders, etc.), and the processing cup assembly 1 It is directly inserted into the main machine 2, and the air enters through the air gap between the outer wall of the tool holder assembly 11 and the inner wall of the main machine 2, and then passes through the negative pressure generated by the high-speed rotation of the fan 216 installed at the bottom of the upper connector 112, lower connector 113 and motor rotor 215, Make the external high-pressure airflow pass through the two negative pressure chambers set quickly through the set cooling air duct 22 and enter the interior of the host 2, and then follow the heat dissipation holes 261 of the base 26 to quickly discharge the heat in the host 2 to achieve The purpose of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com