Fully-automatic suspender nailing and storing integrated machine

An all-in-one, fully automatic technology, applied in clothing, clothing, protective clothing, etc., can solve the problems of inconvenient and long-term sorting and storage operations, and achieve the effect of convenient transmission and convenient and close fit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

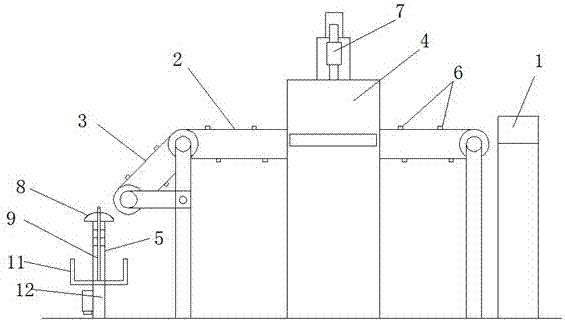

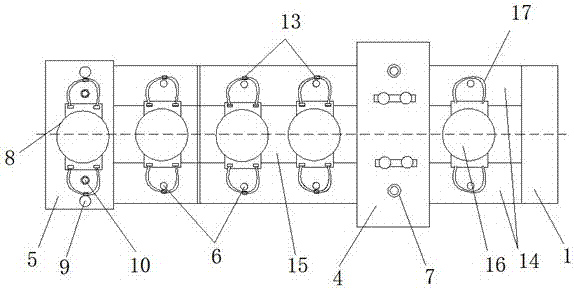

[0015] Embodiment 1: as figure 1 , 2 A kind of full-automatic nail belt storage all-in-one machine shown in and 3, described all-in-one machine comprises feeding platform 1, material transmission belt 2, nail belt operating platform 4 and storage platform 5, described storage platform 5 and feeding The table 1 is arranged at both ends of the material conveying belt 2 respectively, and the nail belt operating table 4 is arranged in the middle of the material conveying belt 2, and an inclined unloading section is provided between the material conveying belt 2 and the storage table 5 3. The material conveyor belt 2 is composed of a cloth cover conveyor belt 15 and two sling conveyor belts 14, the cloth cover conveyor belt 15 is arranged between the two sling conveyor belts 14, and the sling conveyor belt 14 is evenly distributed There are a plurality of protruding sling positioning blocks 13, and the storage platform 5 is composed of an arc support platform 8, a spacer column 10...

Embodiment 2

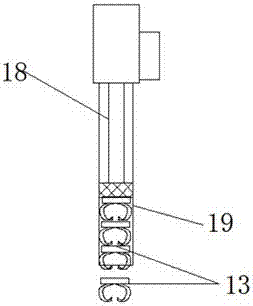

[0016] Embodiment 2: as figure 1 , 2 As shown in and 3, the magnetic buckle compactor 7 is composed of a press cylinder 18 and a pressure groove 19, and a plurality of buckles 13 with magnetic spacers are vertically distributed in the pressure groove 19; The clamp 7 presses the hanging buckle 13 on the suspender 17, and two hanging buckles 13 are pressed on both sides of each passing mask. When the mouth mask falls from the conveyor belt 3 onto the arc support platform 8, Due to the cooperation between the sling positioning block 6 and the spacing column 10, the hanging buckle 13 is easy to be adsorbed on the positioning column 9, so that the masks are conveniently launched and arranged on the arc support platform 8 one by one.

Embodiment 3

[0017] Embodiment 3: as figure 1 , 2 As shown in and 3, the magnetic buckle compactor 7 is arranged directly above the suspender conveyor belt 14, and the pressing point of the magnetic buckle compactor 7 is arranged on the outside of the suspender positioning block 6; The mask of the operating table 4 needs to be fixed together with the suspender 17 and the cloth cover 16 through the nail belt device. At the same time, the two buckles 13 are pressed onto the suspender 17 through the magnetic buckle presser 7. The overall pressing process , the sling 17 is in an unfolded state, which is convenient for subsequent storage work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com