Patents

Literature

39results about How to "Easy packing job" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

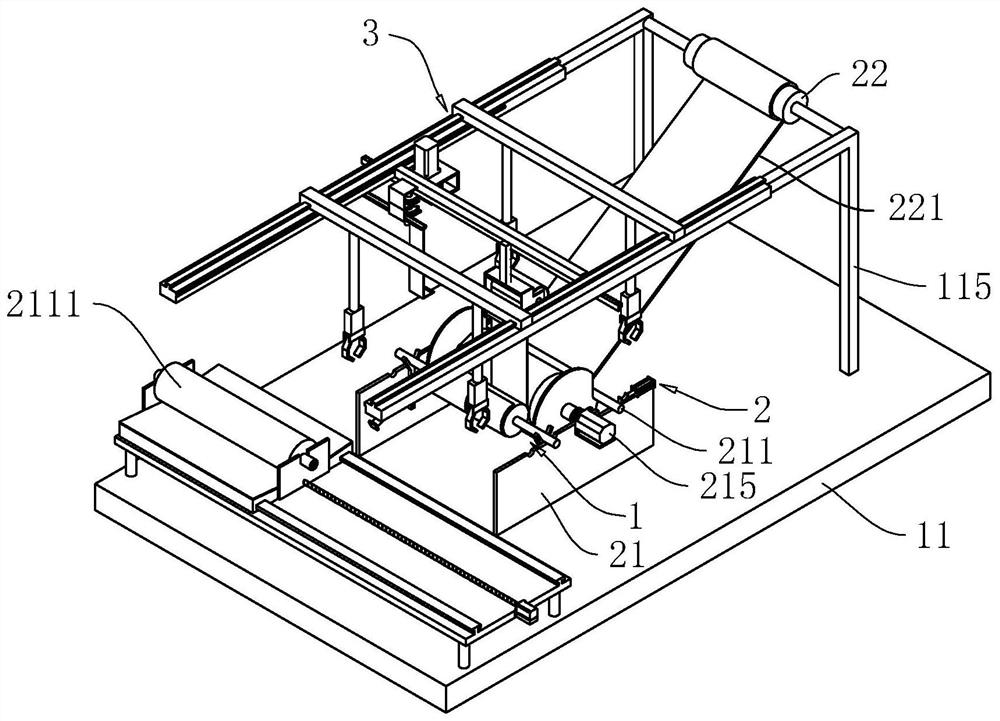

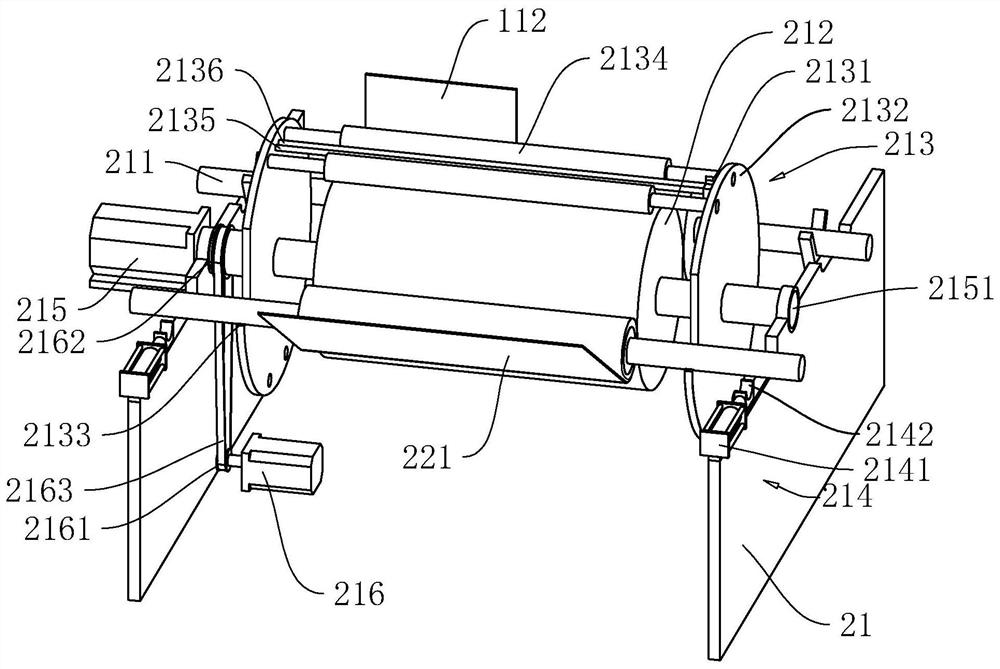

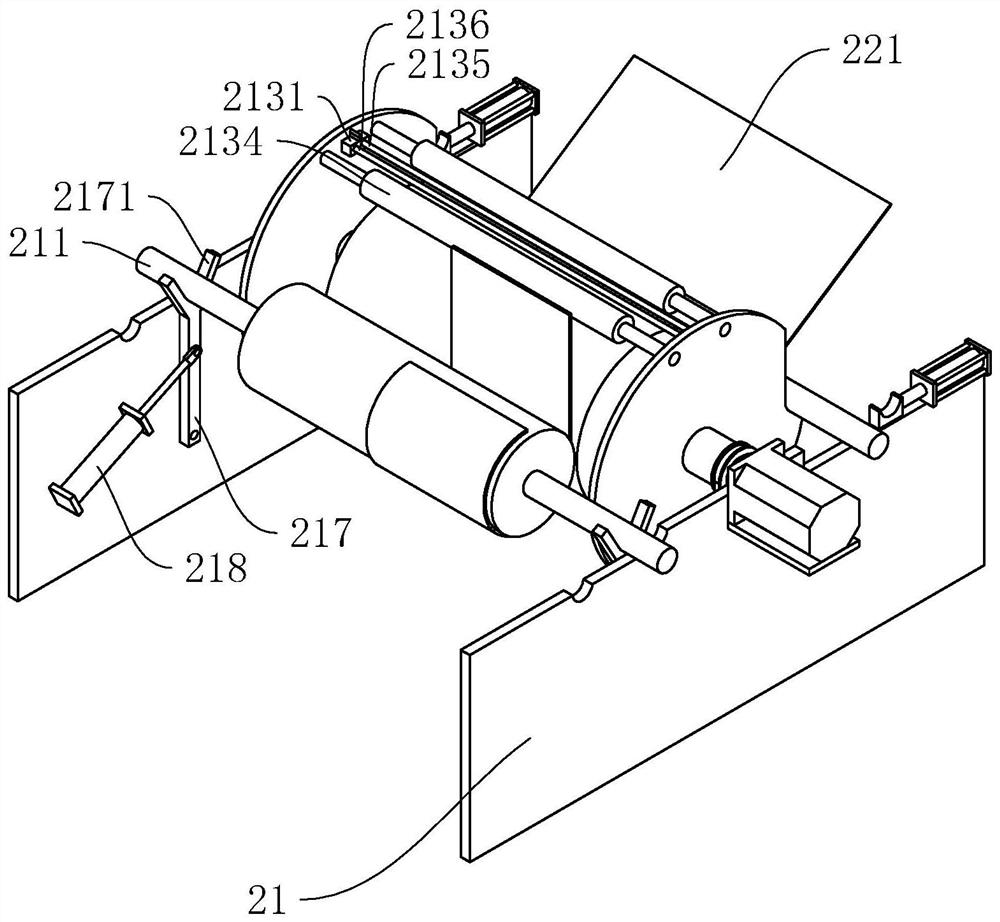

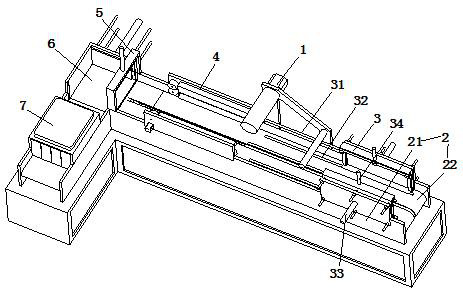

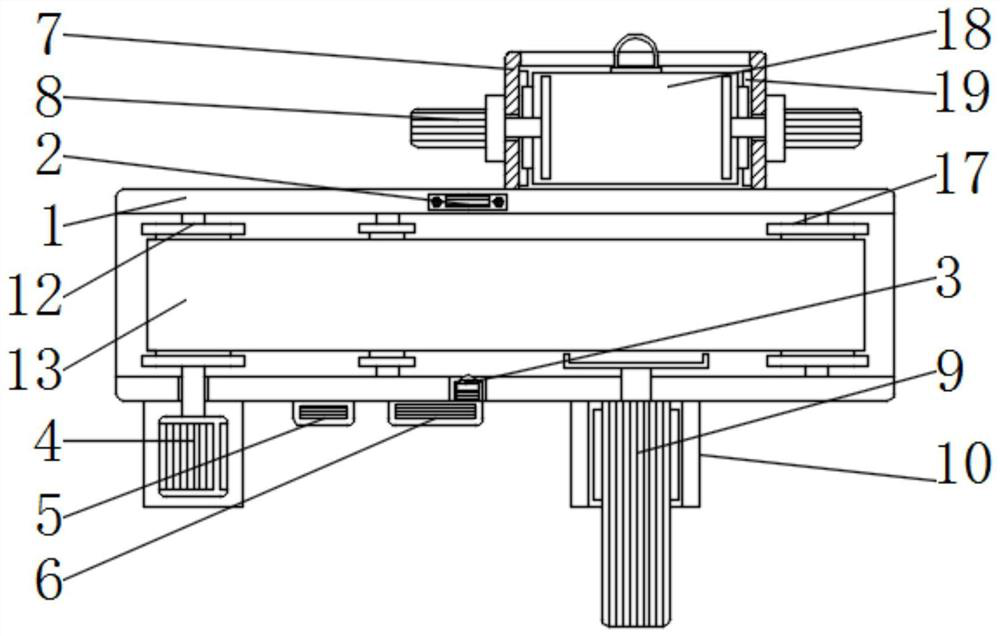

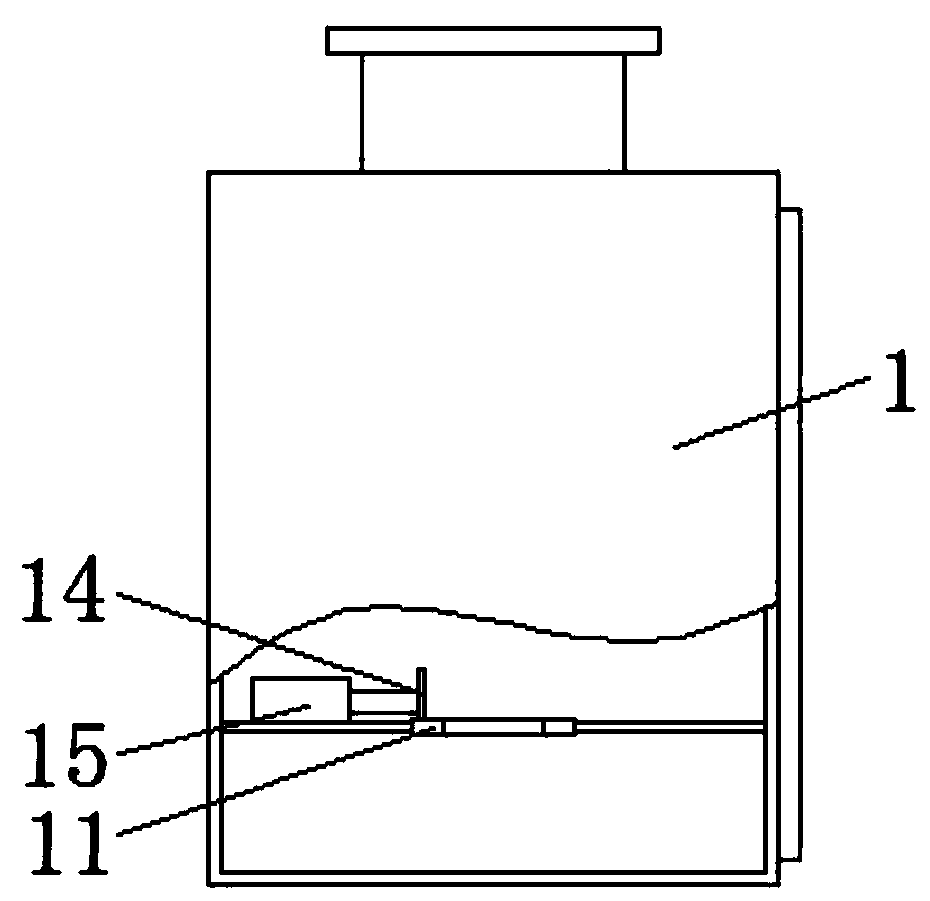

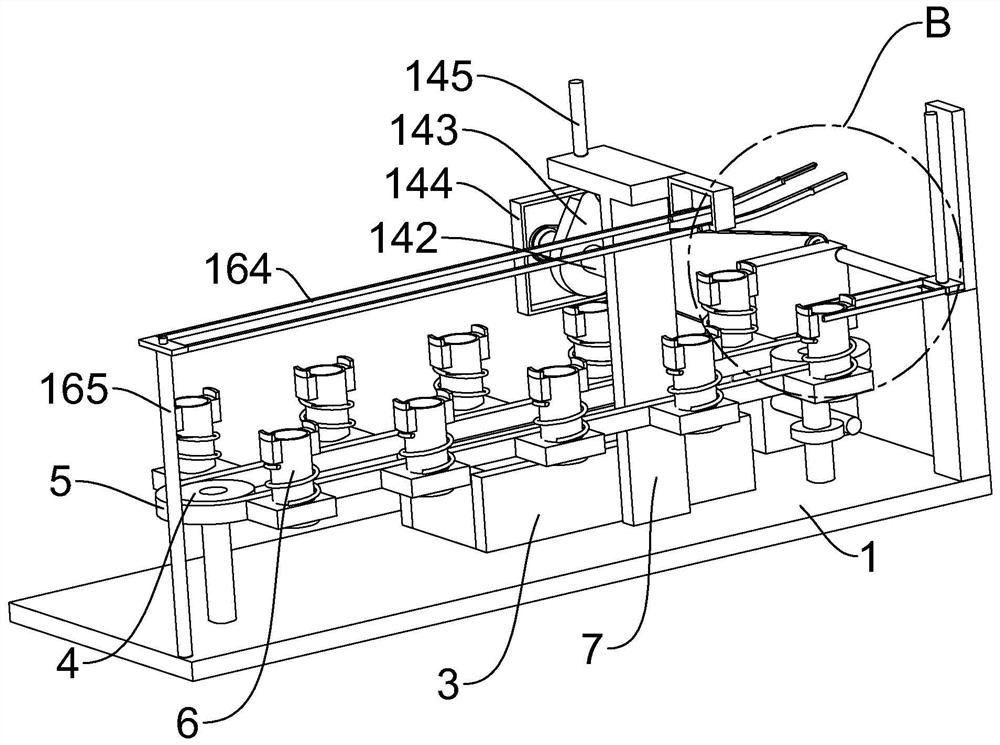

Thin film packaging device and thin film rolling and packaging integrated equipment

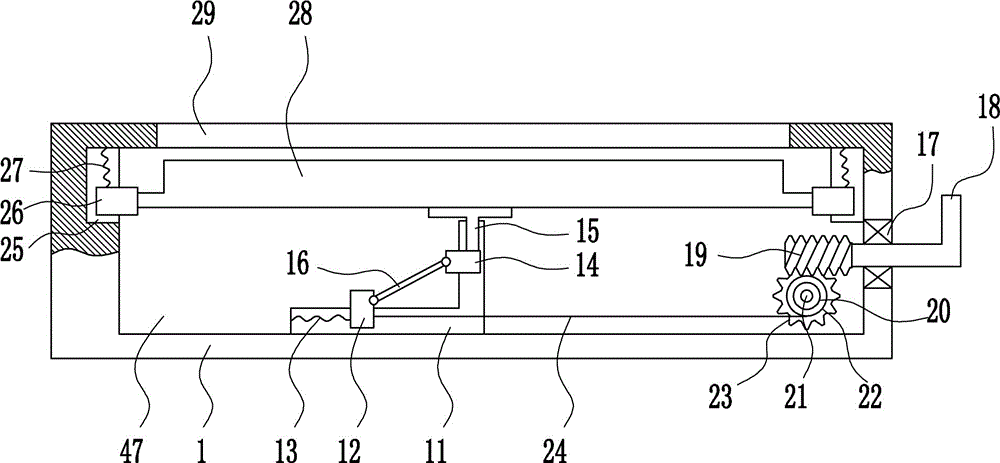

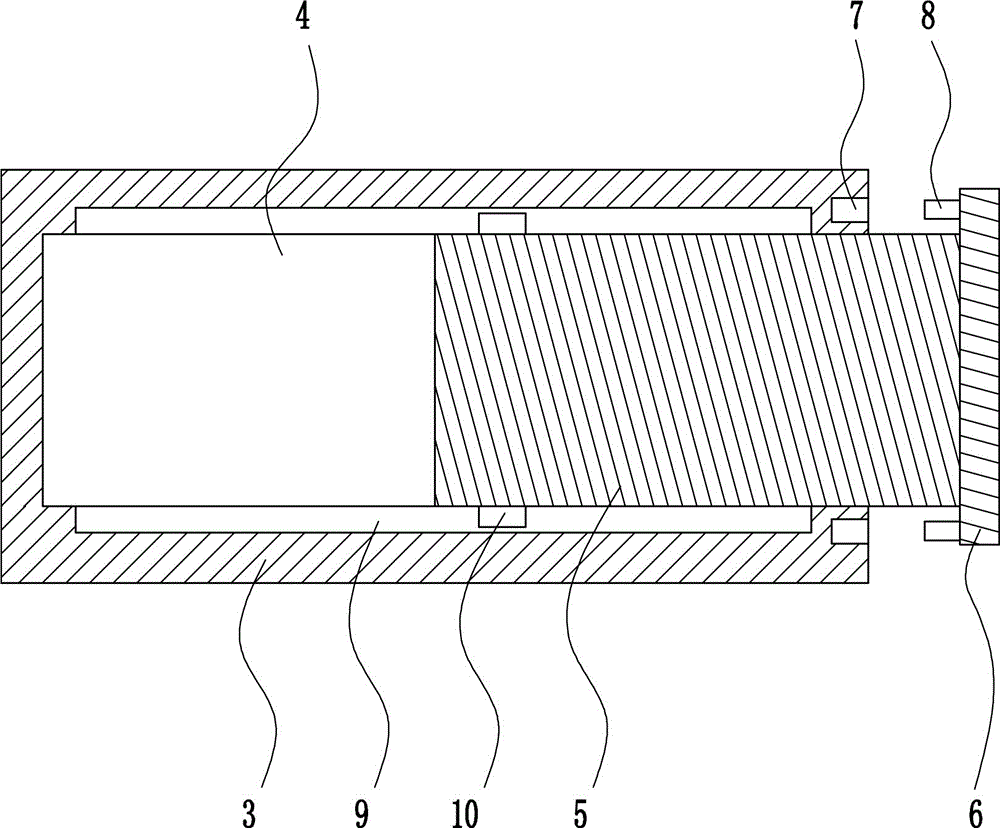

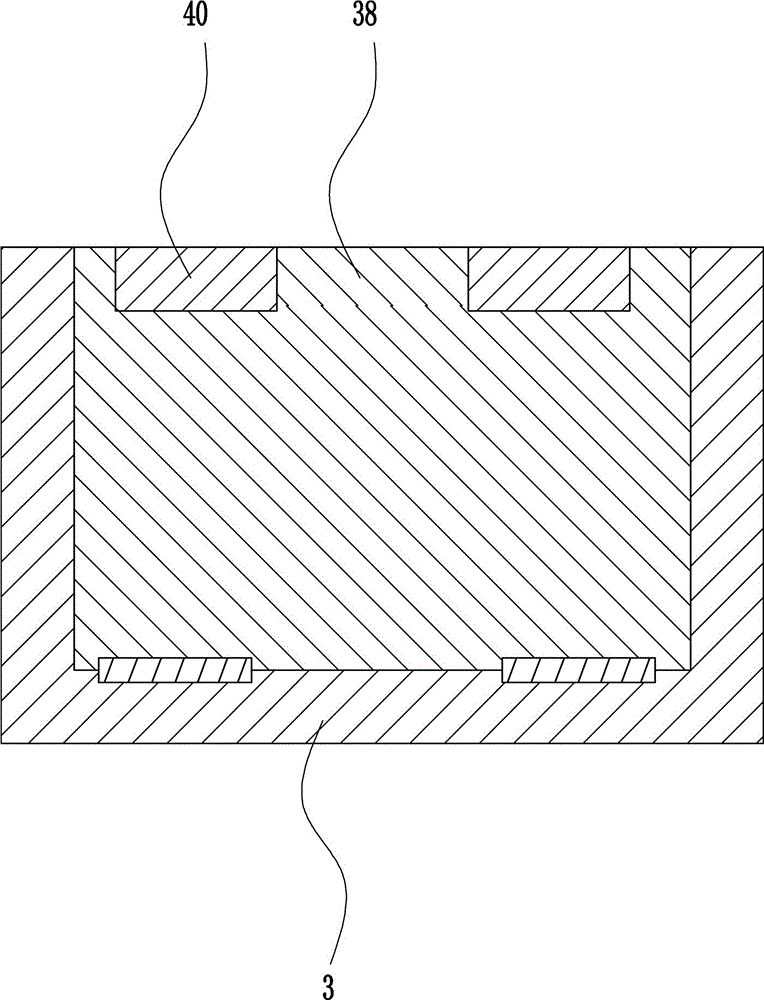

The invention relates to a thin film packaging device and thin film rolling and packaging integrated equipment, and relates to the technical field of thin film production equipment. The thin film packaging device comprises a machine body, a fixing frame is arranged on the machine body, a rolling roller is rotationally connected to the fixing frame, a thin film coiled material is wound around the rolling roller, a support is installed on the machine body, the support is provided with a packaging belt body, the end, away from the support, of the packaging belt body is wound around the thin film coiled material, and the machine body is provided with a driving assembly used for driving the support to move in the axis direction of the thin film coiled material. The driving assembly drives the support to move in the axis direction of the thin film coiled material, the thin film coiled material is rotationally connected with the fixing frame, then the packaging belt body is spirally wound on the thin film coiled material, the thin film coiled material can be tightened, the possibility that the thin film coiled material is loosened is reduced, labor is saved, and the packaging efficiency is improved.

Owner:常州新达力塑料机械有限公司

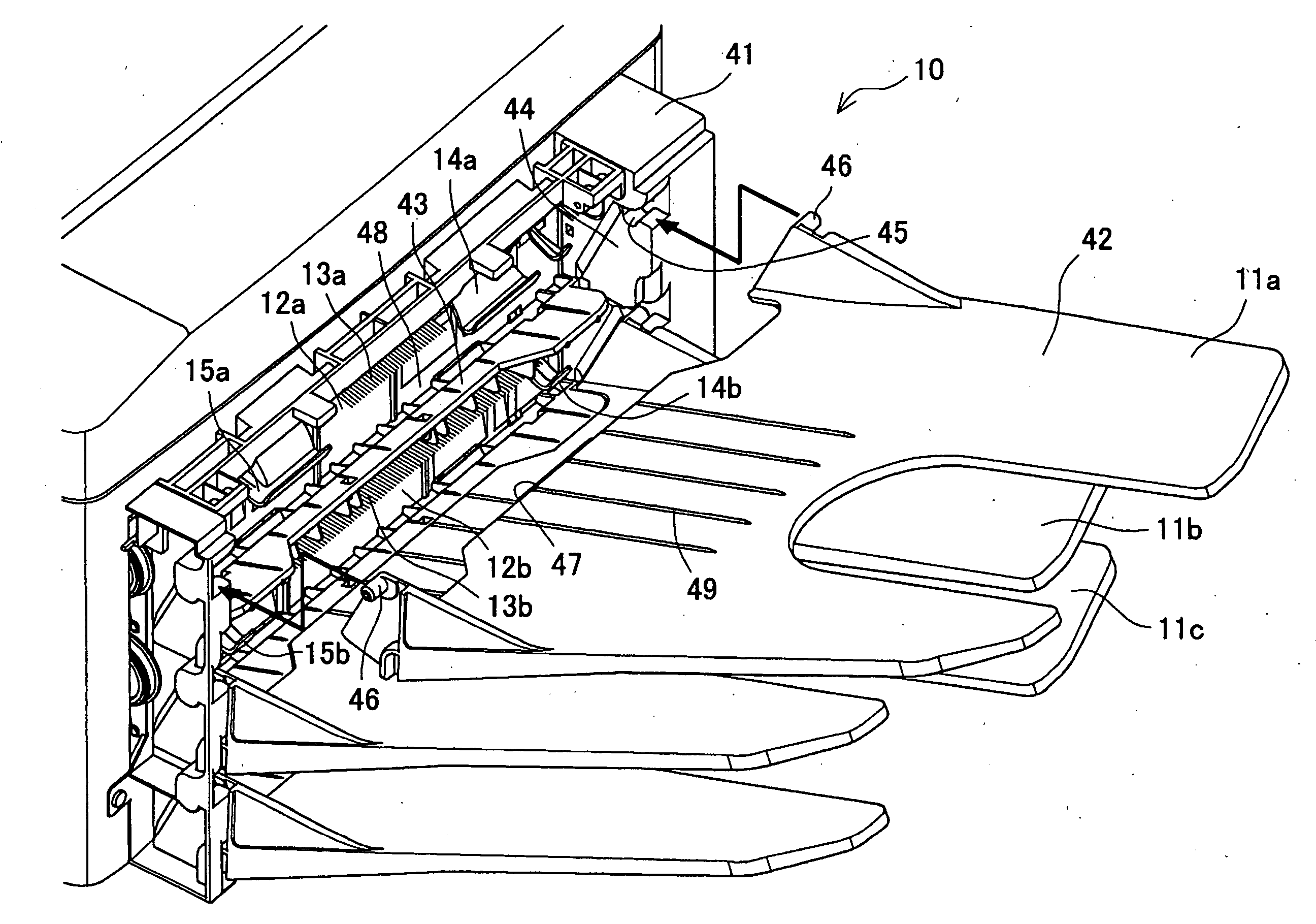

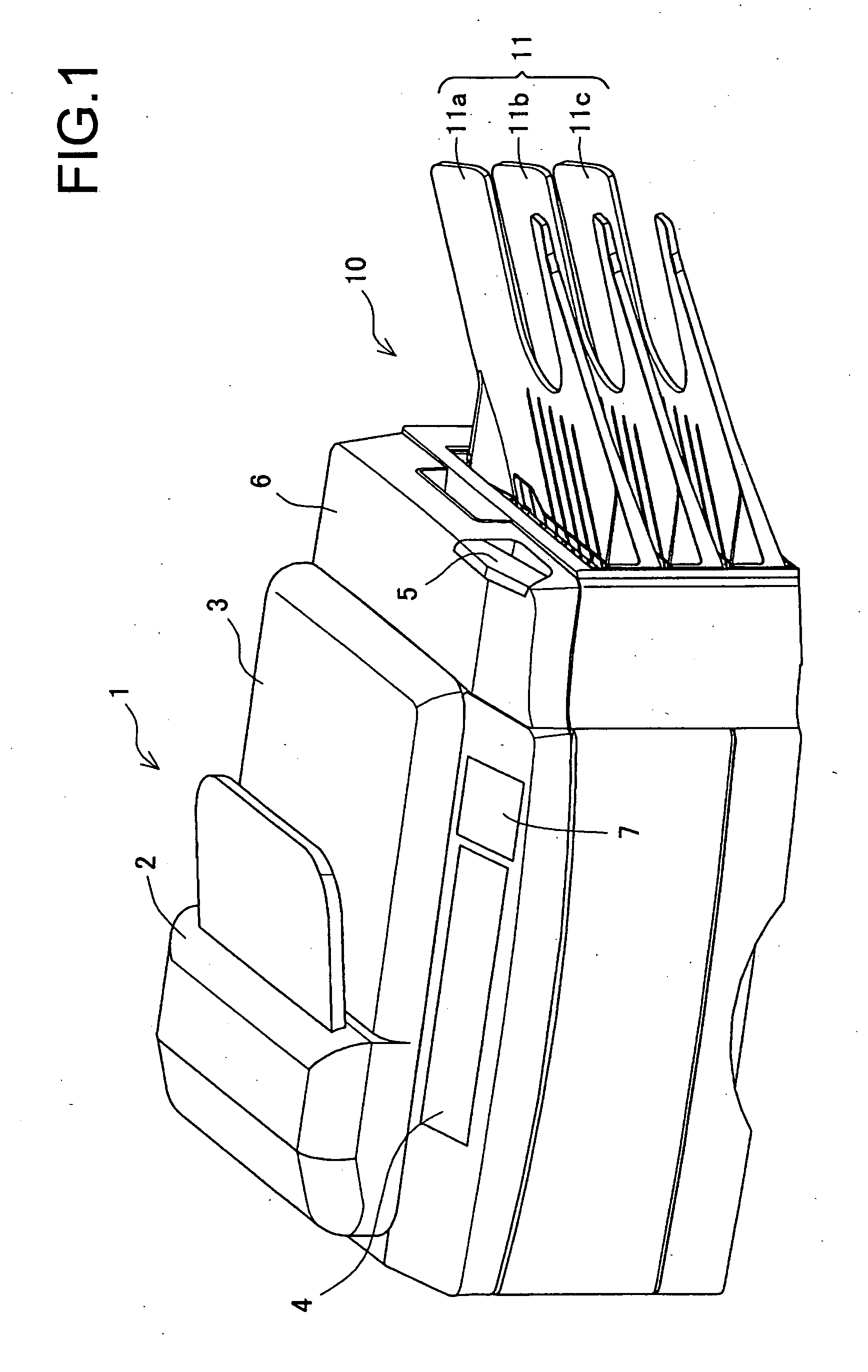

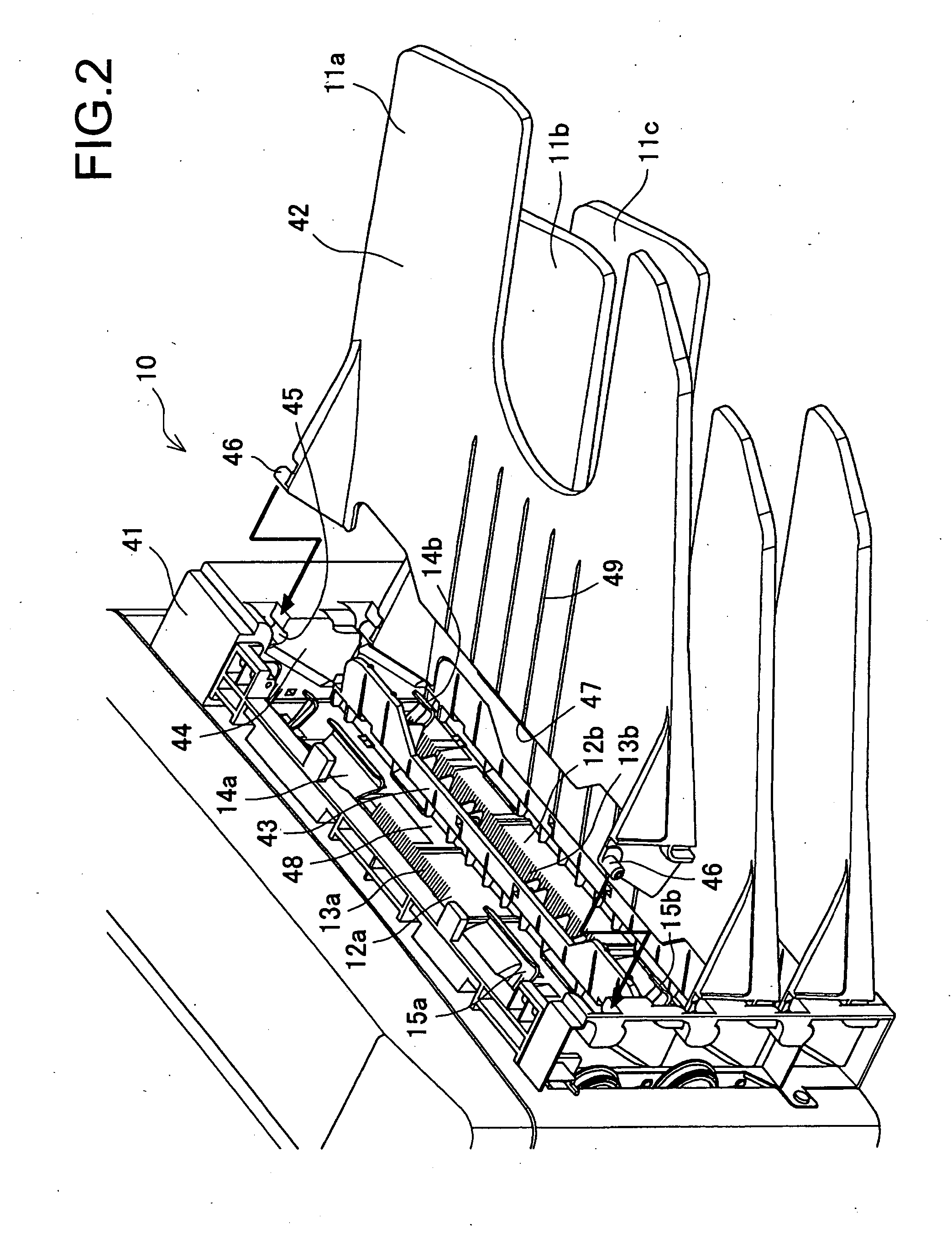

Sheet discharge tray and a multiple bin sorter equipped with the same

A sheet discharge tray for stacking discharged sheets has a detachable member detachably mounted to a main unit from which the sheets are discharged, and a fastening member, attached to the main unit, for fastening the detachable member to the main unit. By mounting the detachable member to the main unit, the tray is configured to link the detachable member and the fastening member, thereby increasing the structural rigidity of a multi-bin sorter. The sheet discharge tray ensures the rigidity of the apparatus, makes packaging work easier when shipping the product, has a compact structure, and is capable of protecting accessory parts such as a static electricity discharging member and sheet detecting members.

Owner:NISCA KK

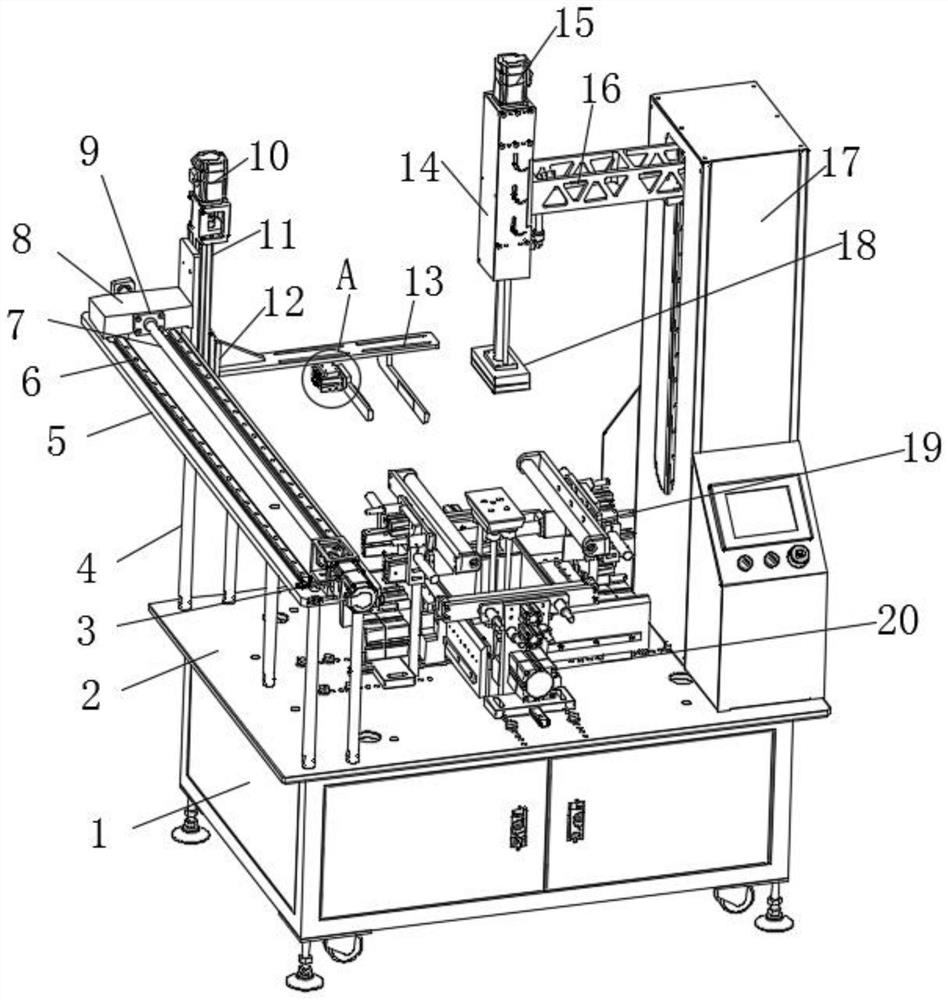

Mobile phone carton packaging machine with guiding and protecting functions

InactiveCN112793835AEasy to install and supportConvenient detachable installation connectionConveyorsPackagingCarton flowCarton

The invention relates to the technical field of mobile phone carton packaging guiding, in particular to a mobile phone carton packaging machine with guiding and protecting functions. The mobile phone carton packaging machine comprises a packaging machine body, a conveying mechanism, a driving mechanism, protecting mechanisms, guiding mechanisms and a limiting mechanism. The conveying mechanism is installed to be in butt joint with the packaging machine body conveniently, the conveying mechanism works under the action of the driving mechanism, cartons needing packaging are conveyed advantageously, the conveyed cartons are tidied and blocked advantageously through the protecting mechanisms installed at the two sides of the top of the conveying mechanism, and the condition that the stacked or stacked cartons flow downwards so that the cartons cannot be used for packaging work is prevented; the guiding mechanisms are installed at the two sides of the top of the conveying mechanism, so that the conveyed cartons can be straightened and placed conveniently, the cartons are installed at a certain position to flow downwards, and the packaging machine body can conduct packaging work conveniently; and meanwhile, through adjustment of the limiting mechanism, the length of the guiding mechanisms can be changed conveniently, and the cartons with different sizes can be conveniently straightened and guided.

Owner:李沁芯

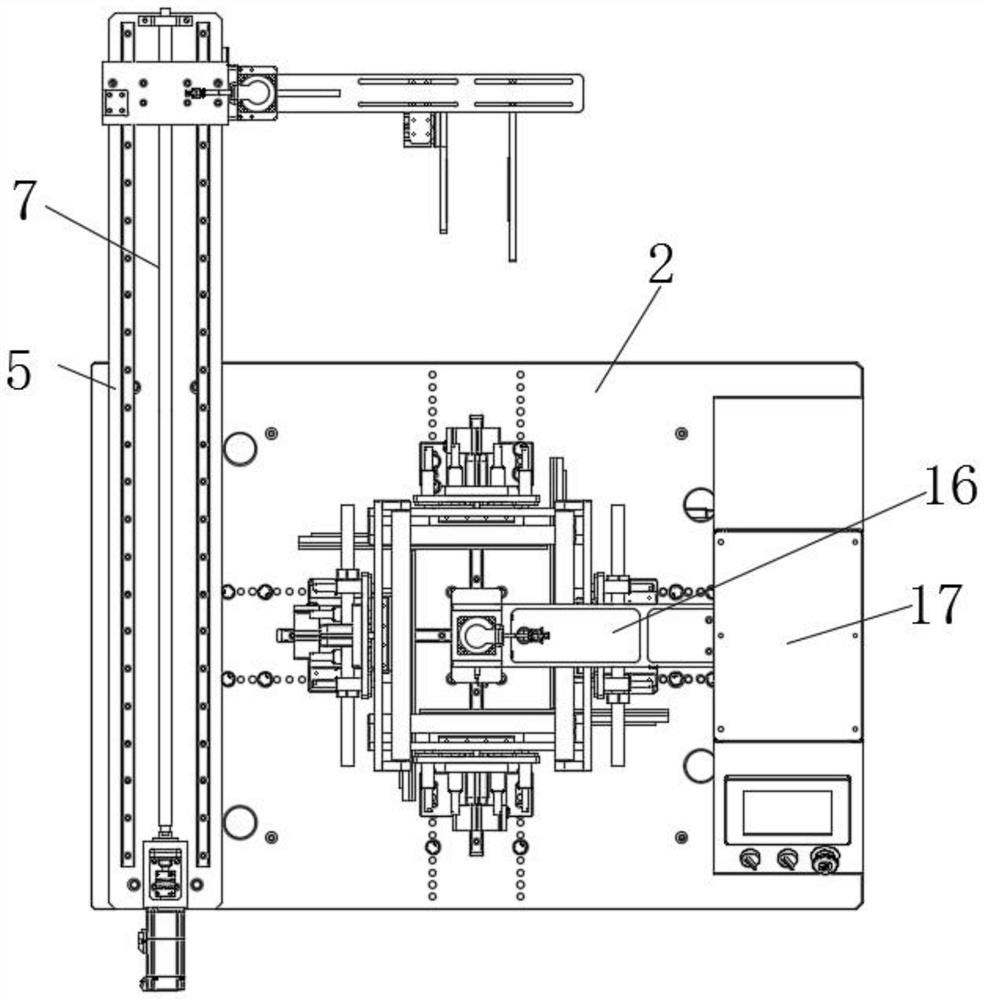

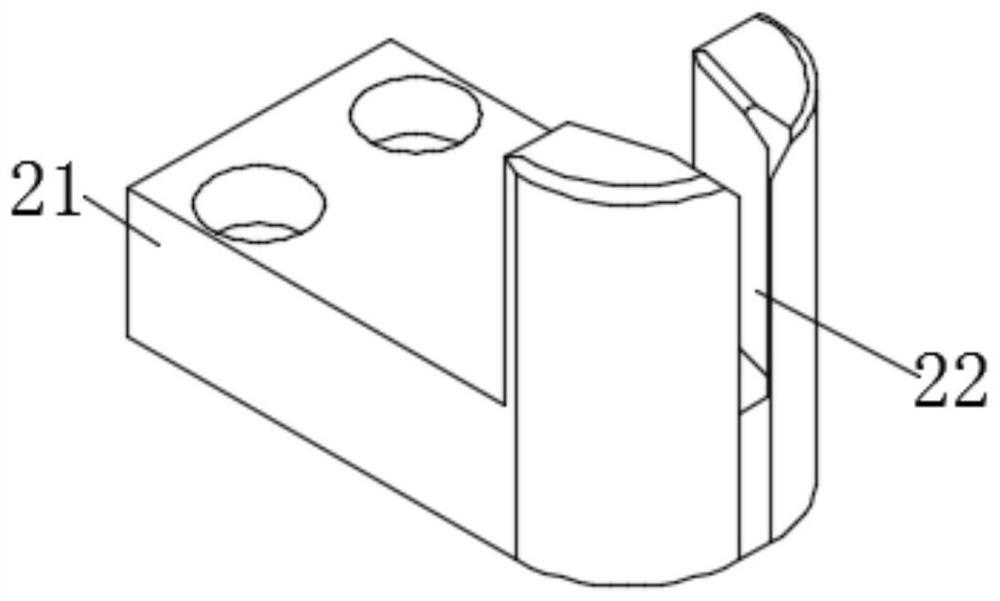

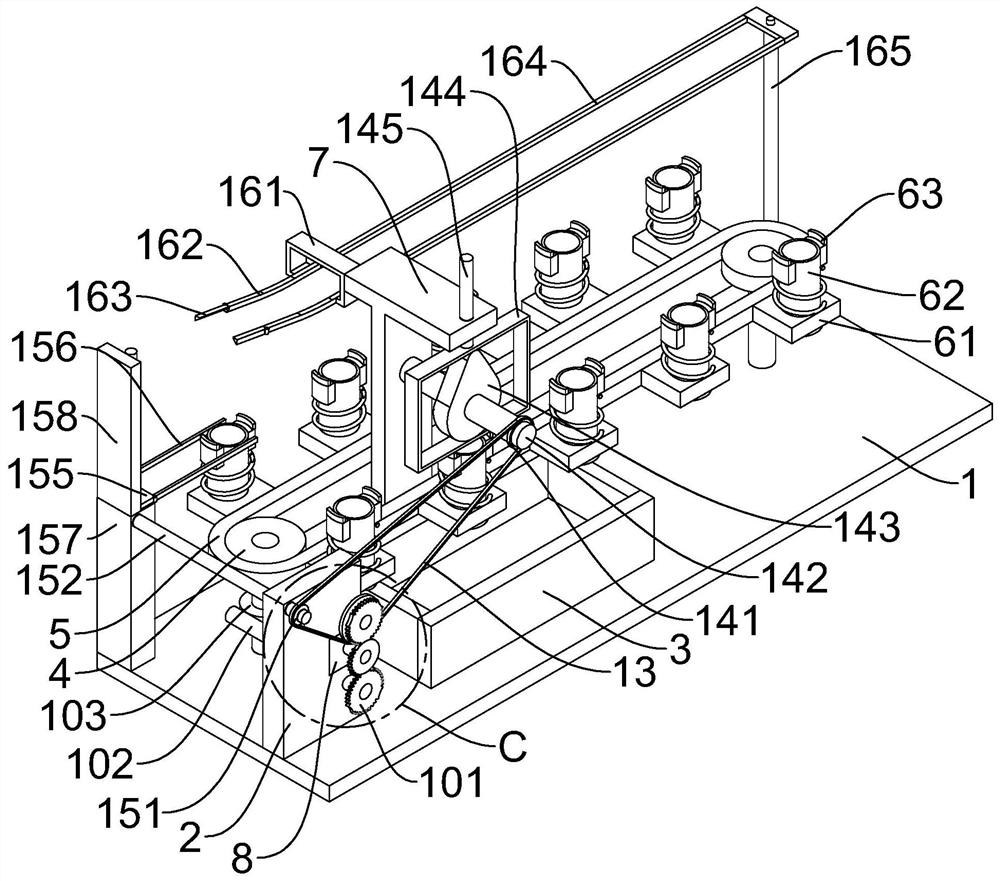

Fully-automatic suspender nailing and storing integrated machine

PendingCN107981443AUniform unfolded stateSave time at workProtective garmentEngineeringFully automatic

The invention discloses a fully-automatic suspender nailing and storing integrated machine which comprises a feeding table, a material conveying belt, a suspender nailing operation table and a storagetable. An inclined discharging section is arranged between the material conveying belt and the storage table, the material conveying belt includes a cloth cover conveying belt and two suspender conveying belts, the cloth cover conveying belt is arranged between the two suspender conveying belts, a plurality of projecting suspender positioning blocks are uniformly distributed on the suspender conveying belts, the storage table comprises an arc-shaped supporting table, limit columns and positioning columns, the arc-shaped supporting table is arranged in the middle of the storage table, the positioning columns are symmetrically mounted on two sides of the arc-shaped supporting table, the limit columns are arranged among the arc-shaped supporting table and the positioning columns, the positioning columns are steel positioning columns, and a magnetic handing fastener presser is arranged on the suspender nailing operation table. According to the integrated machine, auxiliary handing fasteners are additionally mounted on suspenders of masks when the suspenders are nailed, magnetic vertical columns are matched with handing fasteners on the storage table, the stored masks are completely and uniformly unfolded, subsequent taking and packaging are facilitated, time and labor are saved, and the integrated machine is high in automation degree.

Owner:YANCHENG FANGTIAN NON WOVEN PORDUCTS CO LTD

Slitting machine capable of automatically processing defective materials

Owner:湖北烟草民意纸业有限公司

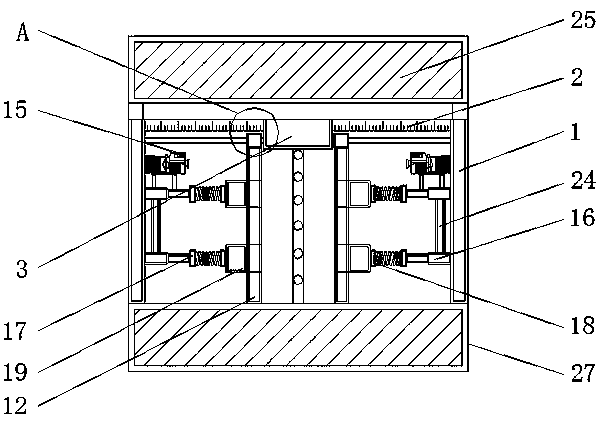

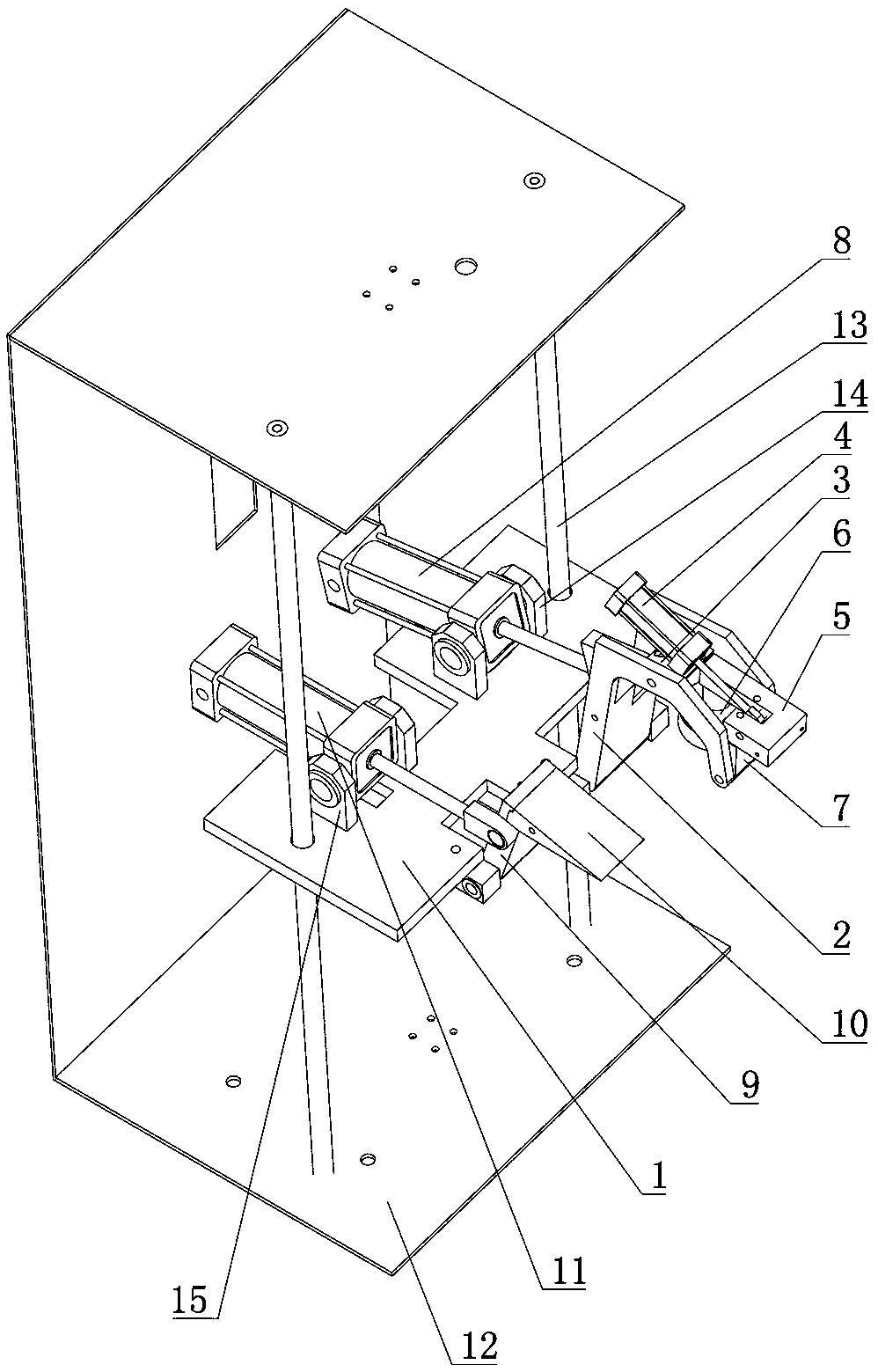

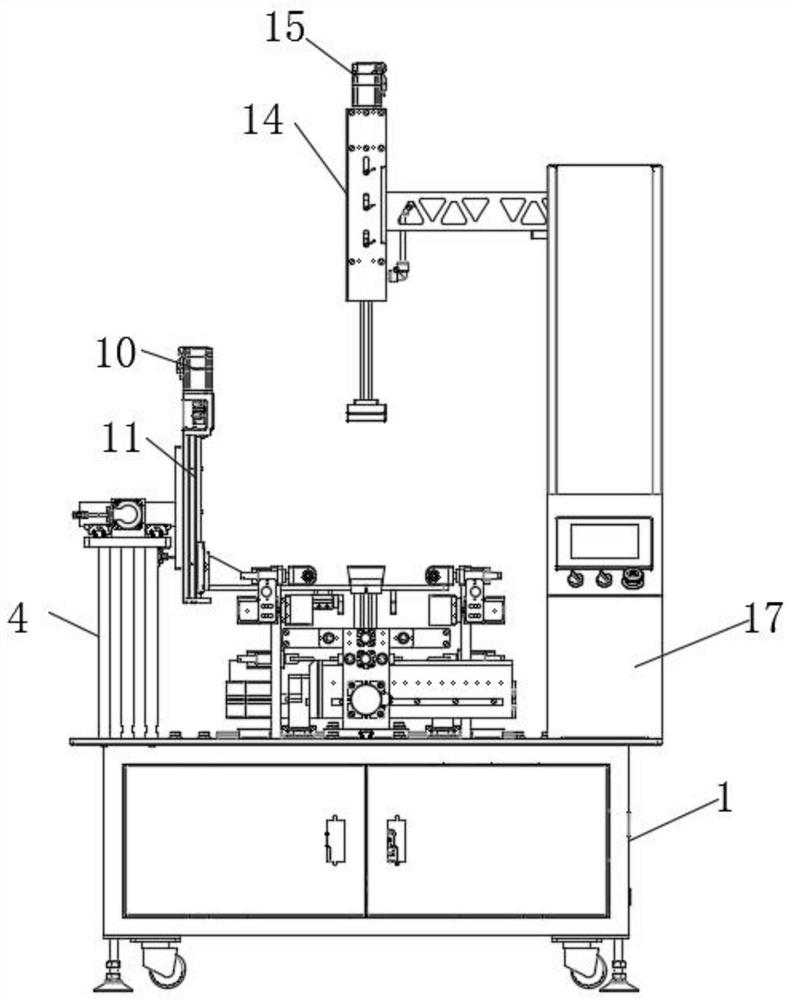

Paper clamping position adjusting device of packaging machine

The invention discloses a paper clamping position adjusting device of a packaging machine. The device comprises a working frame, movable frames, guide rods and conveying belts; a scale plate is installed at the upper end in the working frame, the inner side of the scale plate is provided with a first protective shell, and a partition plate is installed in the first protective shell; retractable springs are connected to the outer ends of spring bases, and second protective shells are placed at the outer sides of the retractable springs; the conveying belts are arranged at the left and right sides of the working frame, a second hydraulic rod is installed above the conveying belts, and an electrostatic adsorption placement plate is connected to the output end of the second hydraulic rod. According to the paper clamping position adjusting device of the packaging machine, first gears are meshed with clamping plates, the clamping plates can be driven to stretch out and draw back in the rotation work process of the first gears, at this moment, movable columns can stretch out and draw back in the out-stretching and back-drawing process of the clamping plates to provide mechanical power toadjust the distance between the guide rods, the whole adjusting process is mechanized, and the reduction of the labor intensity of workers is facilitated.

Owner:云和县鲁家班工艺品经营部

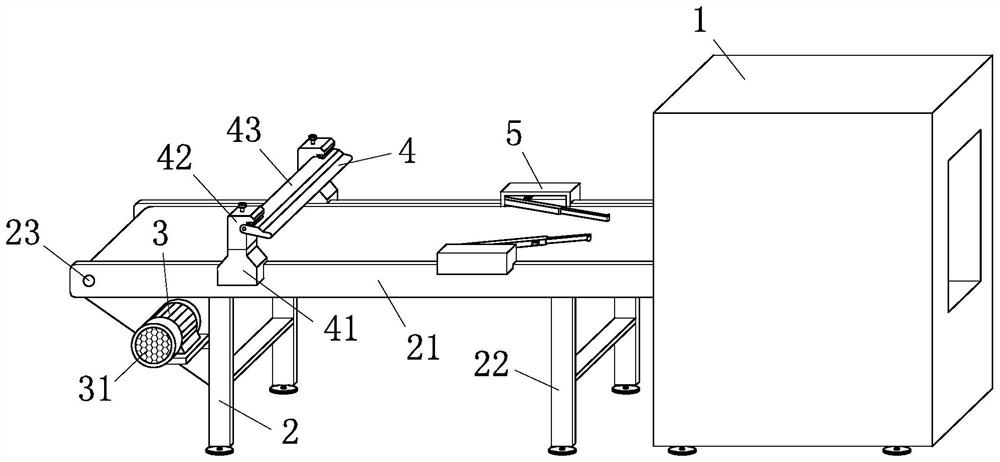

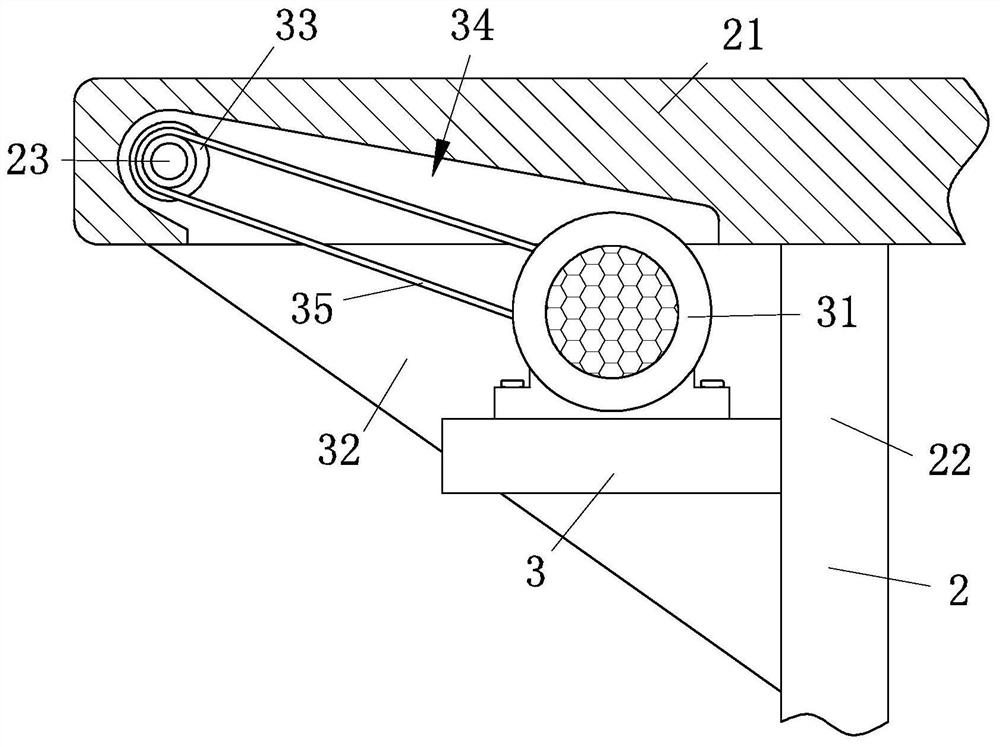

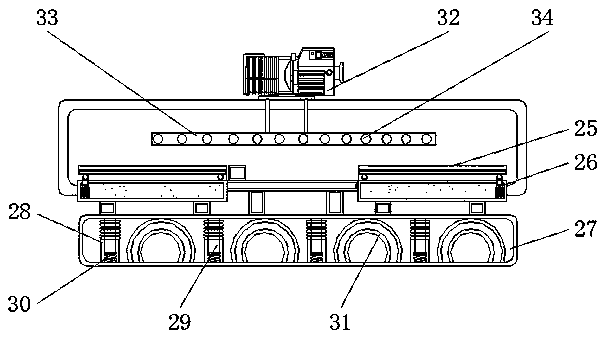

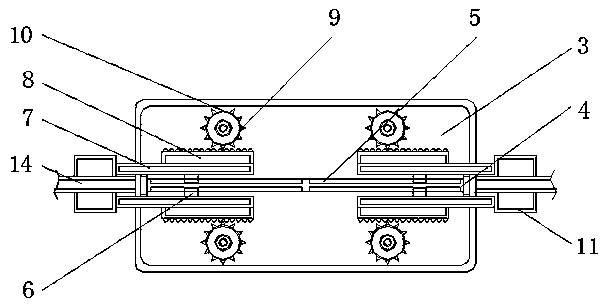

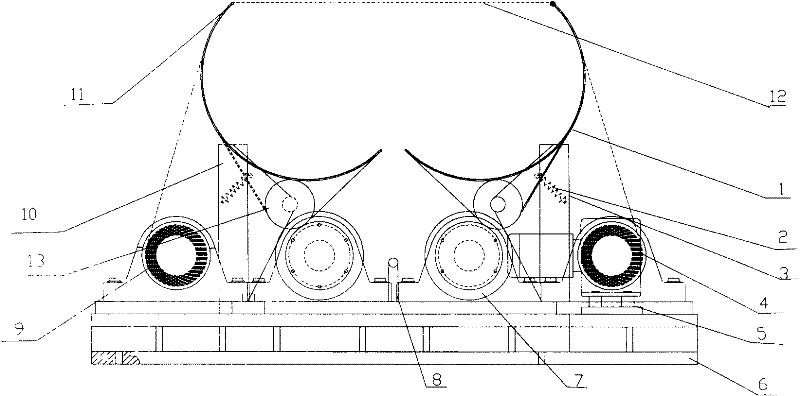

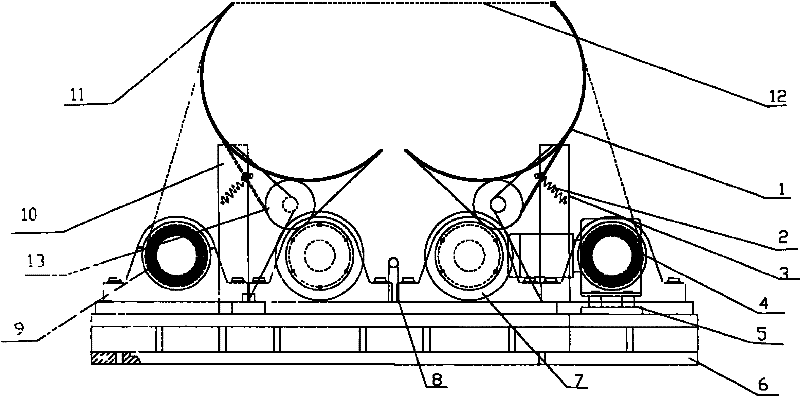

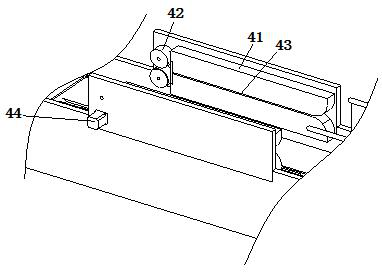

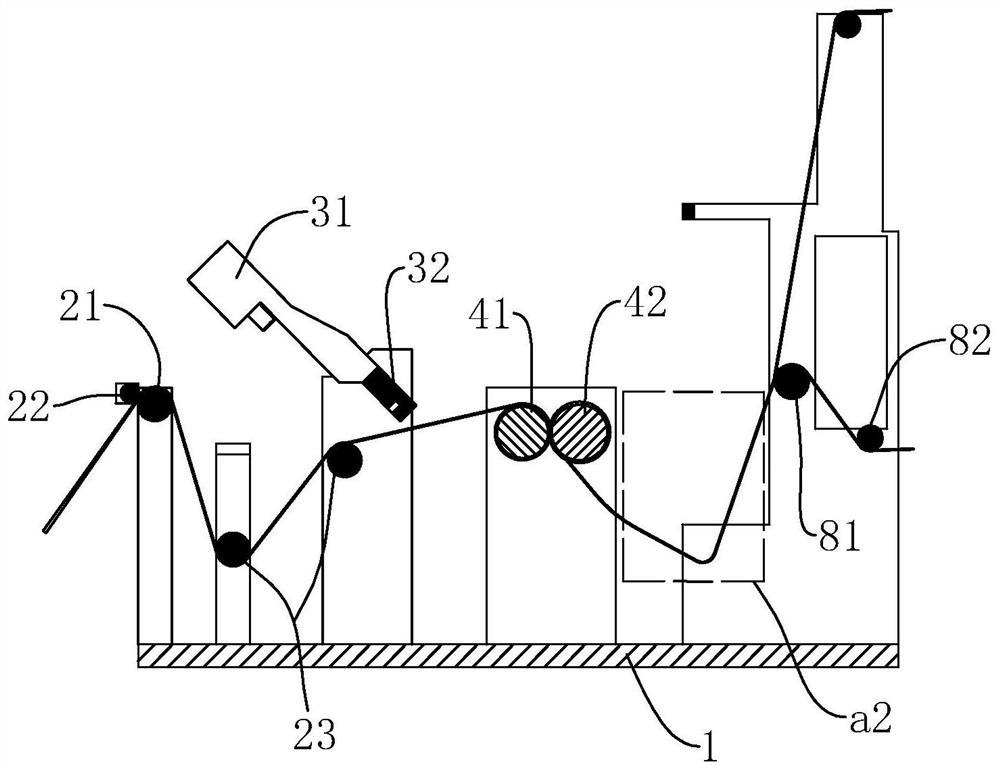

Gravity-type automatic film laminating machine for roll

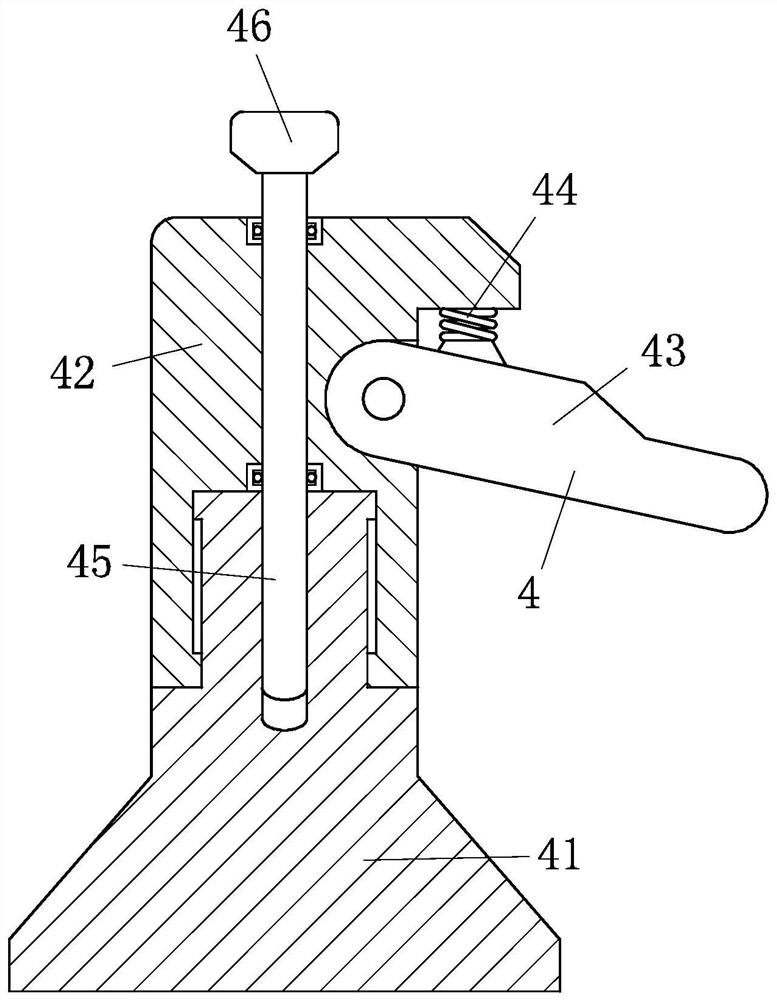

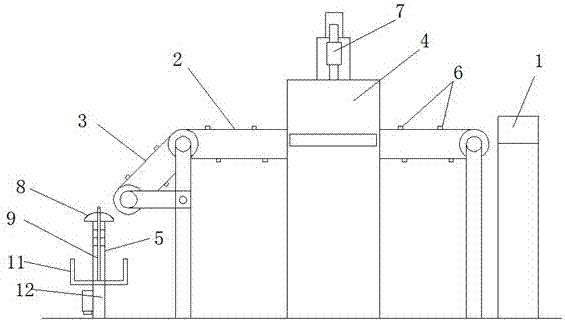

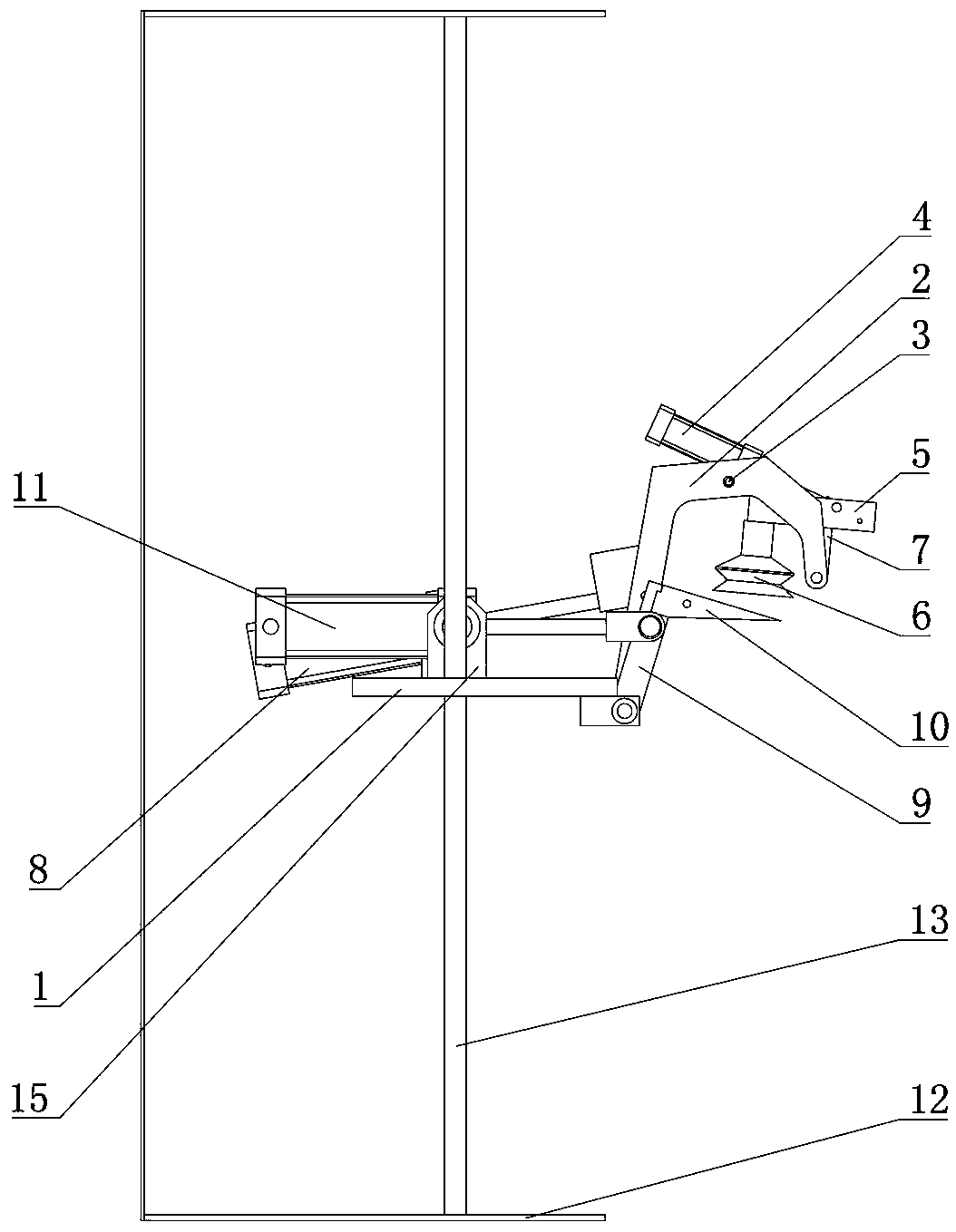

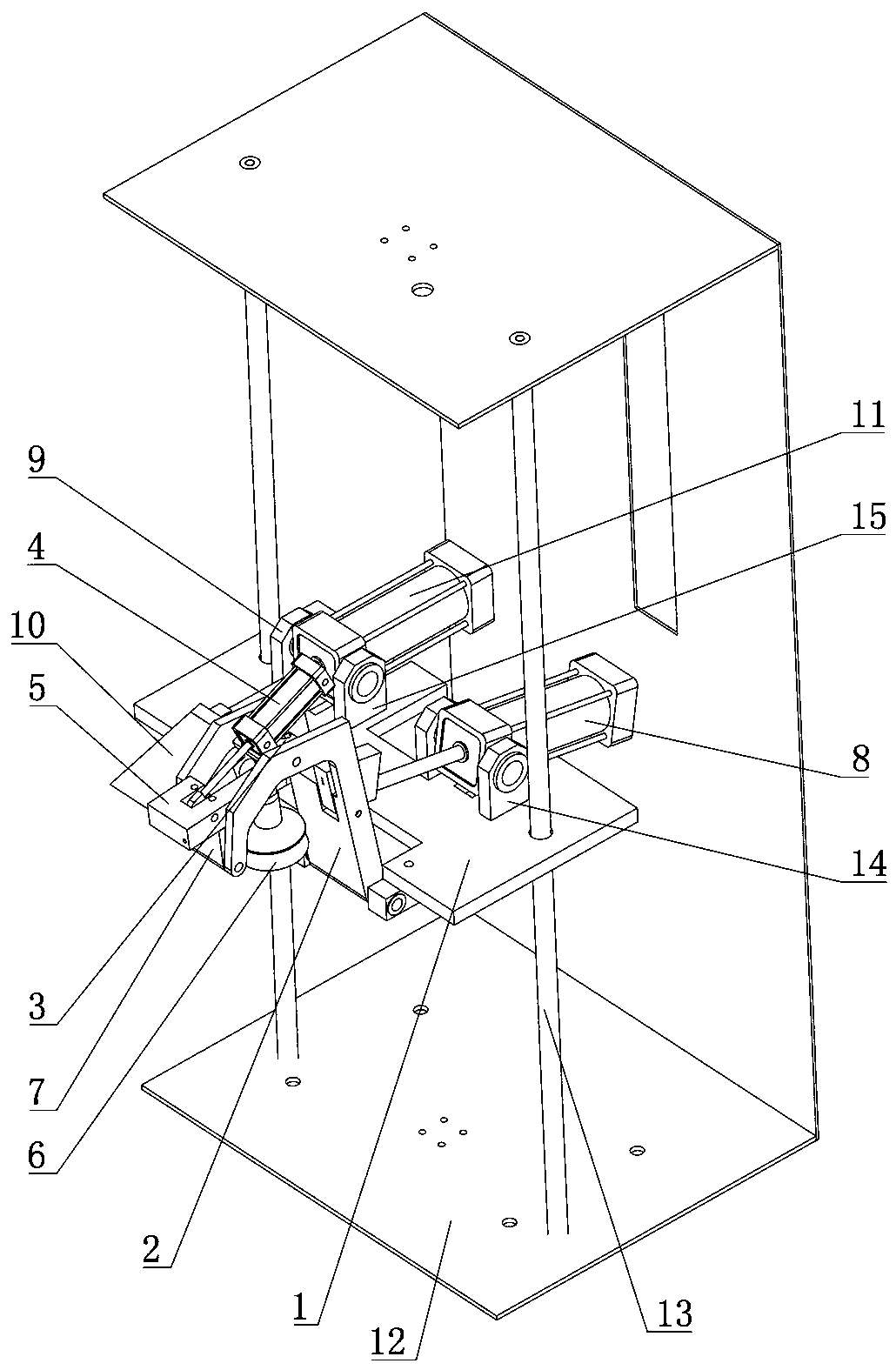

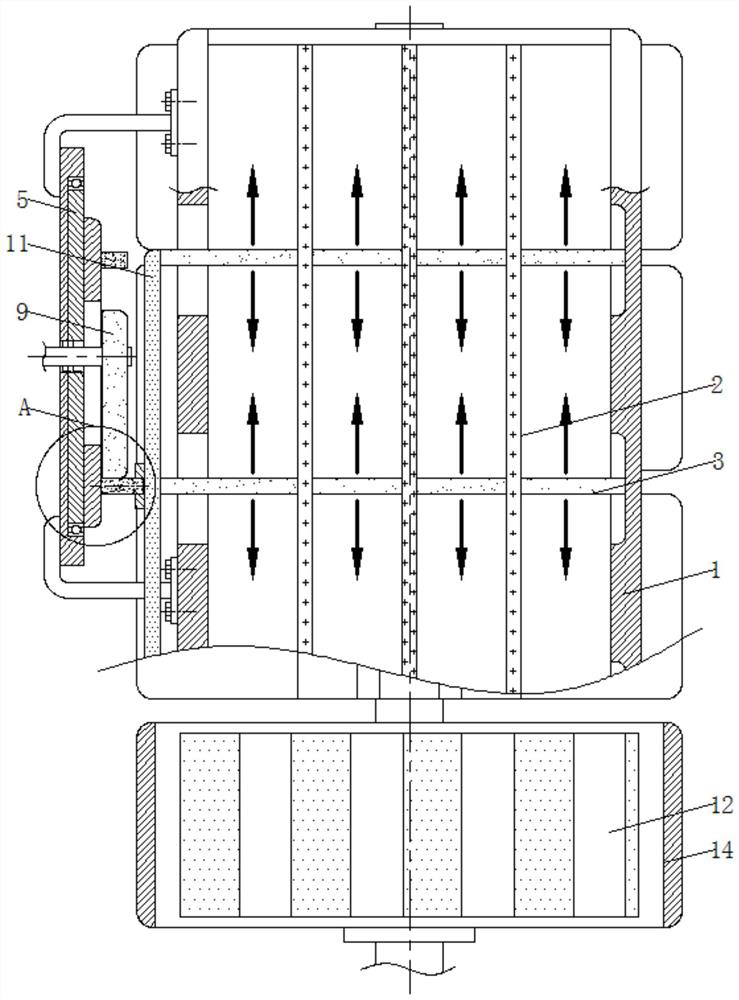

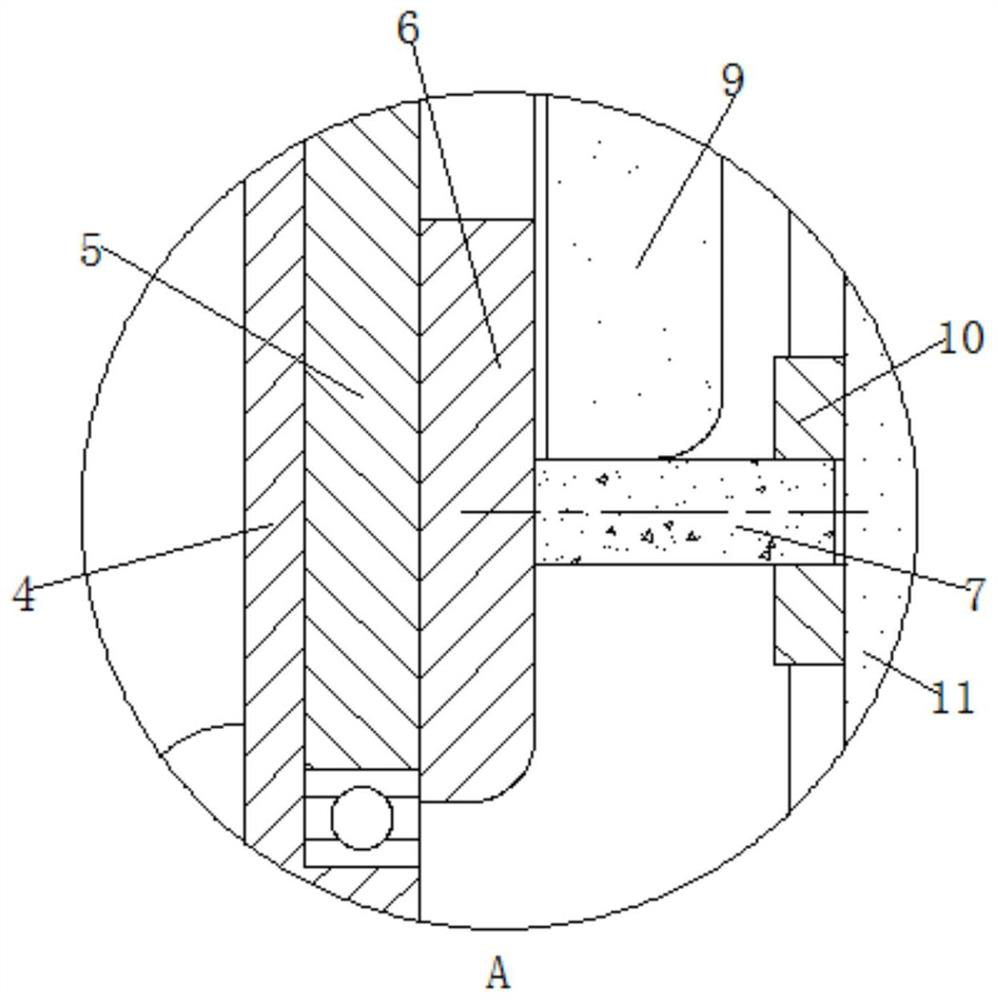

ActiveCN102407950ALabor-saving packagingEasy packing jobWrapping material feeding apparatusEngineeringDrive motor

The utility model relates to automatic film laminating equipment for a roll, in particular to a gravity-type automatic film laminating machine for the roll, which comprises an electric appliance operating platform and a base. The gravity-type automatic film laminating machine is characterized in that the machine additionally comprises a film roll with a plastic film, a waste roll, a pair of supporting rollers, a proximity switch, a roll fastening mechanism and a heating and cutting device; the film roll and the waste roll are respectively arranged on the two sides of the base and are connected through the plastic film and the waste roll is provided with a driving motor; the supporting rollers are arranged in parallel with the film roll and the waste roll and are arranged between the film roll and the waste roll; the proximity switch is arranged between the two supporting rollers; the roll fastening mechanism comprises two semicircular fastening plates which can be opened and closed to form a circle, the fastening plates are supported through supporting frames which are fixed on the base and are arranged on the two sides of the supporting rollers, and the film crosses over the tops of the two fastening plates; the upper ends of the two fastening plates are edges and are provided with heating resistance wires; and the width of the plastic film is larger than the width of the roll to be wrapped. By using the gravity-type automatic film laminating machine, the roll can be packaged in the shortest time.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

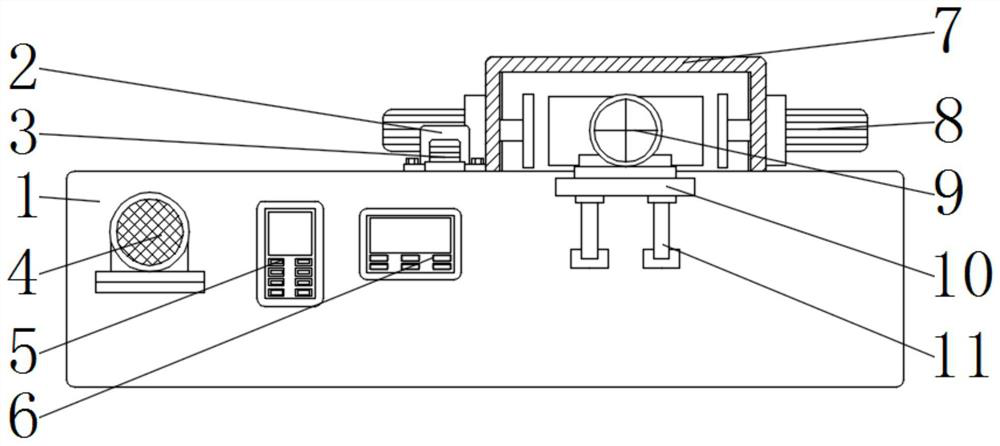

Packaging shell for intelligent servo driver system

ActiveCN106628515AImprove protectionAchieve installationPackaging vehiclesContainers for machinesControl theoryServo drive

The invention relates to a packaging shell and especially relates to the packaging shell for an intelligent servo driver system. The technical problem to be solved by the invention is to provide the packaging shell for the intelligent servo driver system, with convenience in transportation and external protection. In order to solve the technical problem, the packaging shell for the intelligent servo driver system provided by the invention comprises a placement plate, universal wheels, a placement frame, a shielding plate, a moving plate and a first rubber block, wherein the universal wheels are in rotatable connection with the left and right sides of the front and rear parts at the bottom of the placement plate. According to the invention, the universal wheels are used, so that the inconvenience in moving of a servo driver in the transporting and packaging processes can be relieved; the servo driver is protected from being damaged by the external factors by means of pushing and opening the shielding plate, so that an effect of protecting the servo driver is achieved; a protecting rod is arranged, so that the placement frame can be effectively protected and the servo driver can be prevented from being damaged due to compression caused by the external force in the transportation process.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

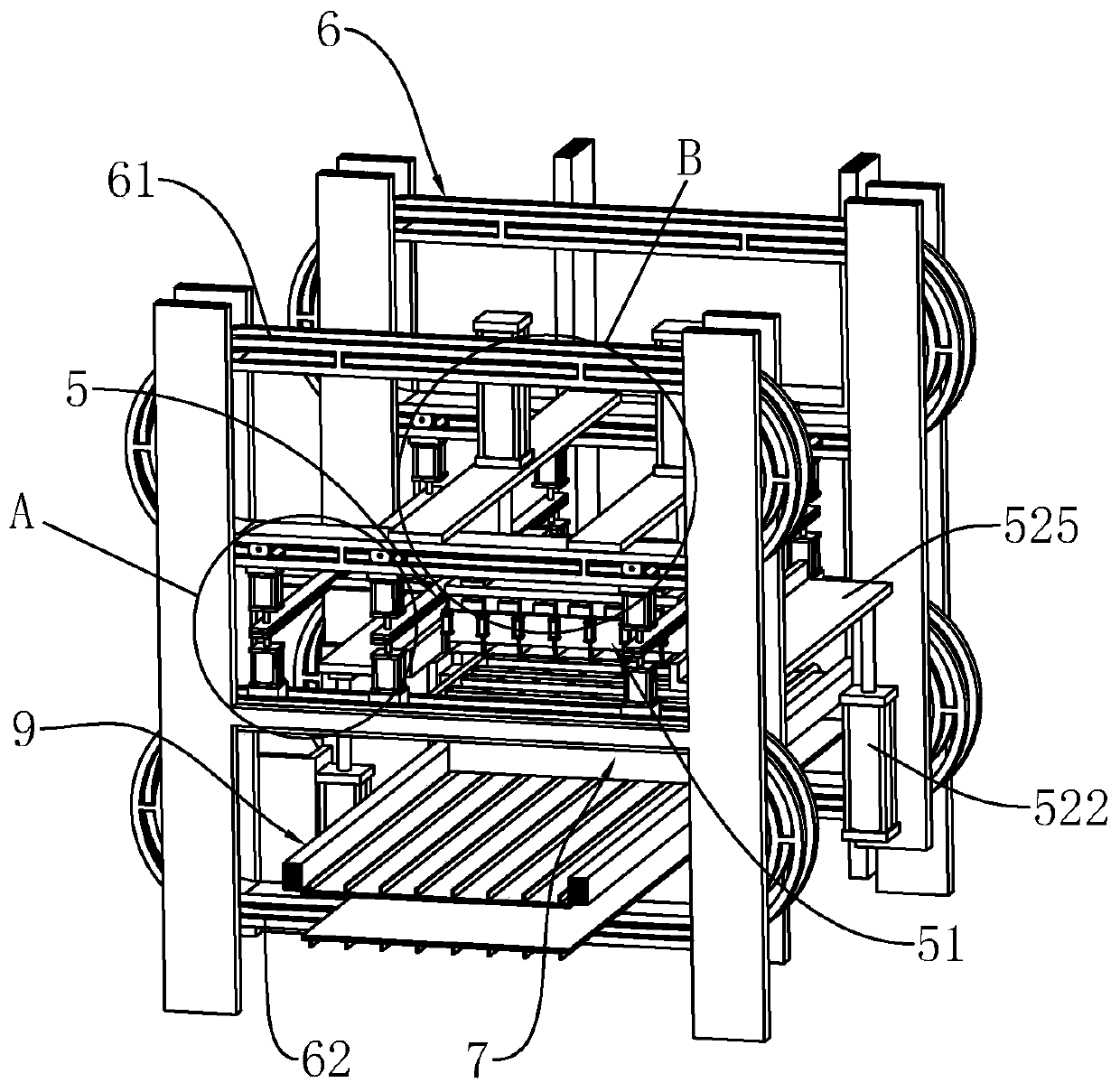

Interlayer paper divider of stacking machine

PendingCN110803529AAvoid wastingIngenious structureStacking articlesArticle feedersHydraulic cylinderEngineering

Provided is an interlayer paper divider of a stacking machine. The problem that double-layer interlayer layer appears during stacking is effectively solved. The interlayer paper divider comprises a fixed disc, and a paper suction mechanism and a paper dividing mechanism are arranged on the fixed disc. The paper suction mechanism comprises a first supporting arm movably mounted at the front end ofthe fixed disc, and a supporting plate is movably mounted at the upper end of the first supporting arm. A first hydraulic cylinder is mounted at the upper end of the supporting plate, and a fixed plate is hinged to the front end of the first hydraulic cylinder. A suction cup is arranged at the lower end of the fixed plate, and a second hydraulic cylinder is arranged at the rear end of the fixed disc. The paper dividing mechanism comprises a second supporting arm movably mounted at the front end of the fixed disc, and a paper weight foot is arranged at the upper end of the second supporting arm. A third hydraulic cylinder is arranged at the rear end of the fixed disc. The interlayer paper divider is ingenious in structure and novel in conception, the piled interlayer paper is separated intosingle layers through the paper suction mechanism and the paper dividing mechanism, and the later packaging procedure is convenient; and the double-layer paper is avoided, material waste is effectively avoided, and the work efficiency is improved.

Owner:河南宝钢制罐有限公司

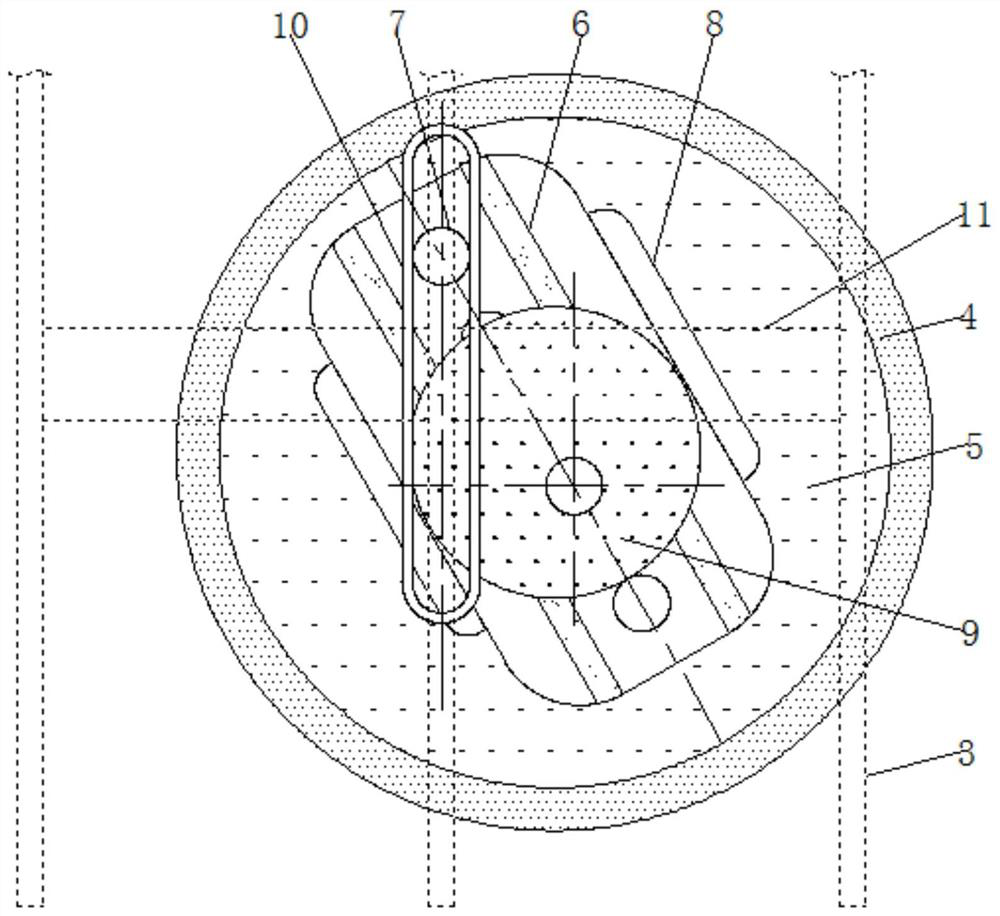

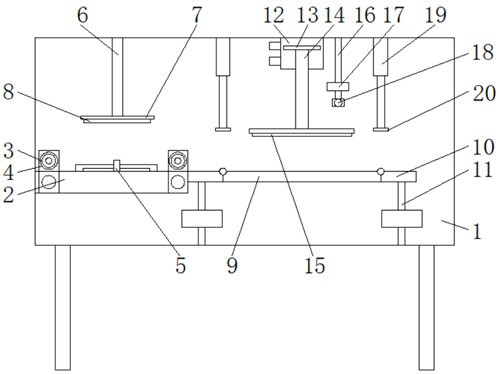

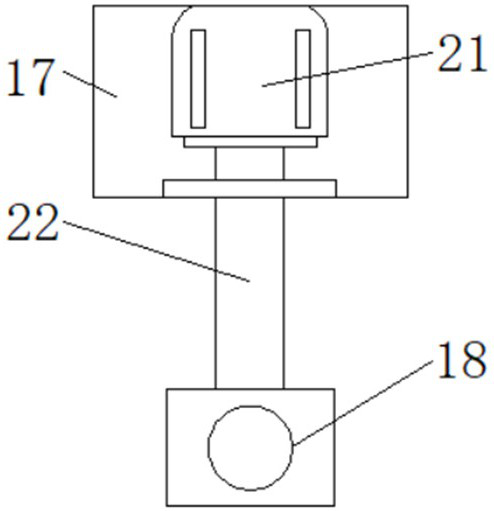

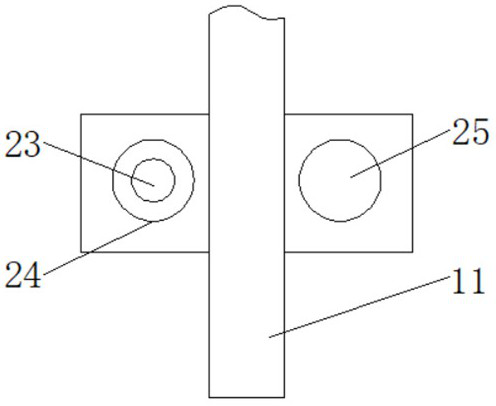

Diode arranging and conveying device based on intelligent manufacturing

InactiveCN112582321AEasy to transportEasy to fall intoSemiconductor/solid-state device manufacturingConveyor partsDevice materialMechanical engineering

The invention relates to the technical field of manufacturing of special equipment for semiconductor devices, and discloses a diode arranging and conveying device based on intelligent manufacturing. The device comprises a shell, a side plate is arranged in the shell, a movable plate is arranged in the shell, a base is arranged on the side surface of the shell, and a turntable is arranged in the base. The diode arranging and conveying device based on intelligent manufacturing comprises a rotary disc, a sliding disc is arranged on the surface of the rotary disc, a push column is arranged on thesurface of the sliding disc, a sliding rail is arranged on the surface of the rotary disc, an eccentric disc is arranged on the side face of the sliding disc, and a push ring is arranged on the surface of the push column. According to the diode arranging and conveying device based on intelligent manufacturing, the eccentric disc and the push column are used in cooperation, the push ring and the supporting plate are used in cooperation, the supporting plate and the movable plate are used in cooperation, the positions of the diodes can be adjusted, the diodes can fall between the side plates conveniently, conveying of the diodes is facilitated, the diode arrangement efficiency is improved, and workers are prevented from being hurt.

Owner:杭州元簧商贸有限公司

Printing and packaging process based on degradable film

PendingCN113501166AEasy packing jobEasy to useWrapping material feeding apparatusWrappingGear wheelElectric machinery

The invention discloses a printing and packaging process based on a degradable film, and relates to the technical field of printing and packaging. The printing and packaging process comprises a workbench, wherein a conveyor belt is arranged inside the workbench; a transmission roller is arranged above the conveyor belt; cleaning cloth is movably mounted on the outer part of the transmission roller; fixed boxes are arranged at front and rear sides of the conveyor belt; small electric pushing rods are fixedly mounted inside the fixed boxes; and opposite surfaces between the small electric pushing rods are fixedly connected with small motors. According to the printing and packaging process disclosed by the invention, an electric telescopic pole is started, and drives a folding plate to perform lifting operation, the folding plate is lifted onto a workpiece, and a drive motor is started, and drives packaging paper to perform rotary operation through a drive gear block, a driven gear block, a gear column and an angle plate, so that packaging work is conveniently performed on the workpiece. The packaging mechanism is simple in structure, is convenient to use, and is convenient for packaging work on four sides of the workpiece, so that production efficiency is improved.

Owner:广东宝丰数字印刷科技有限公司

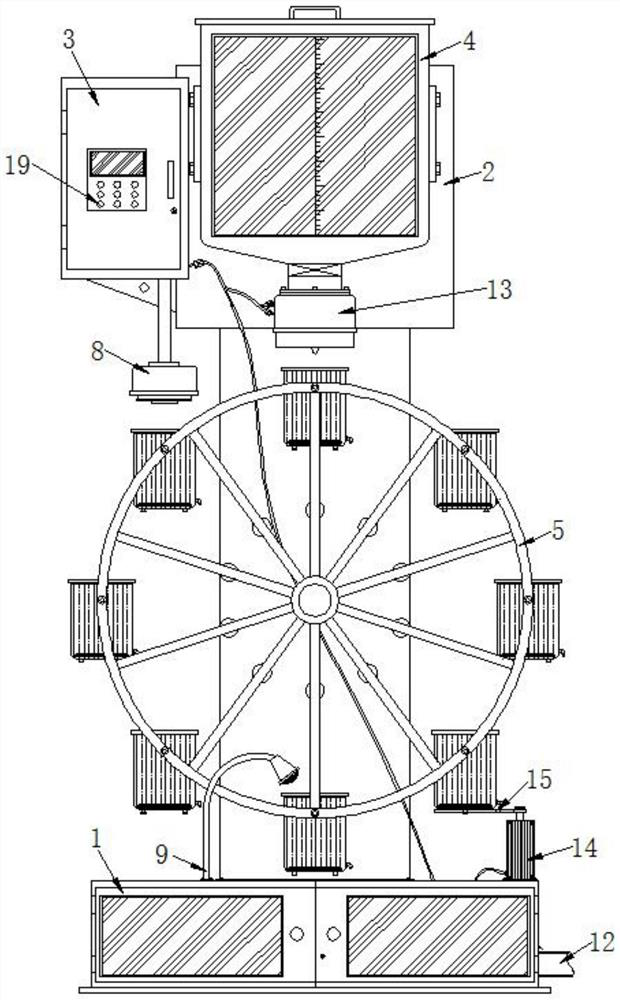

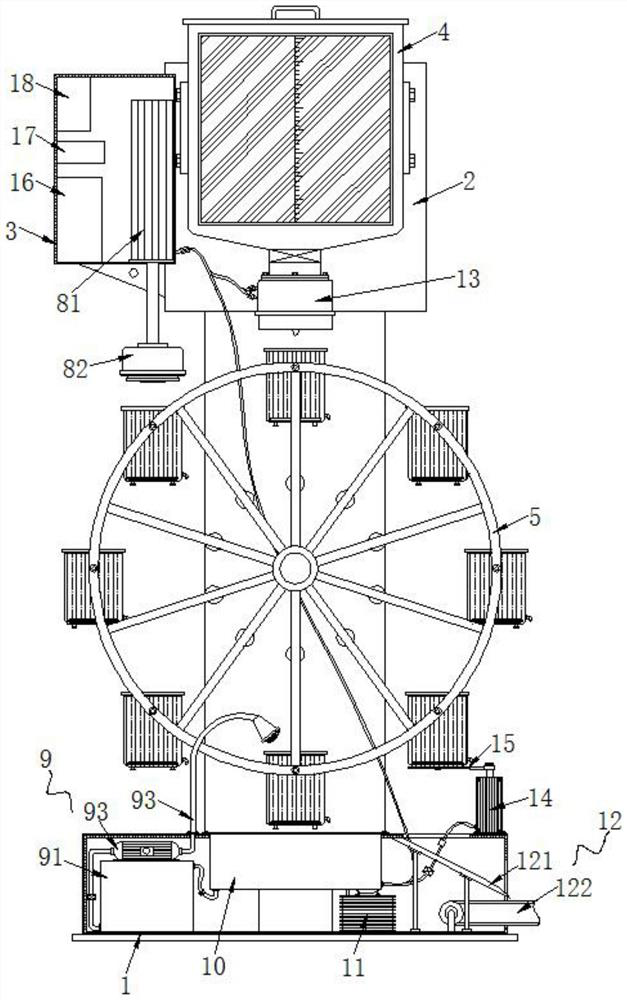

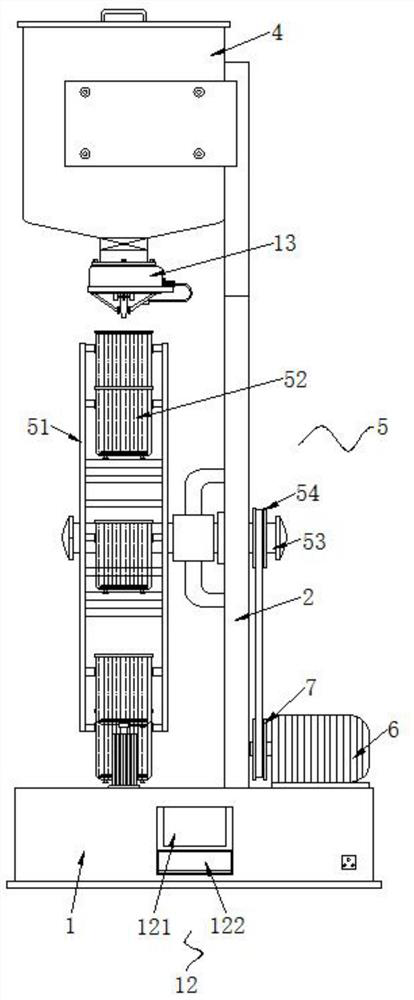

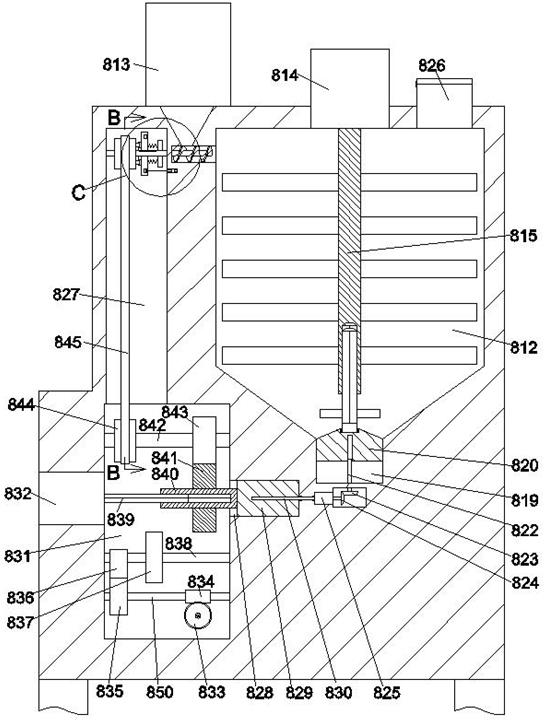

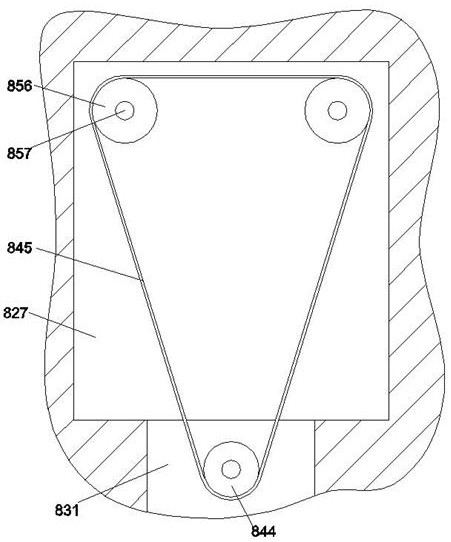

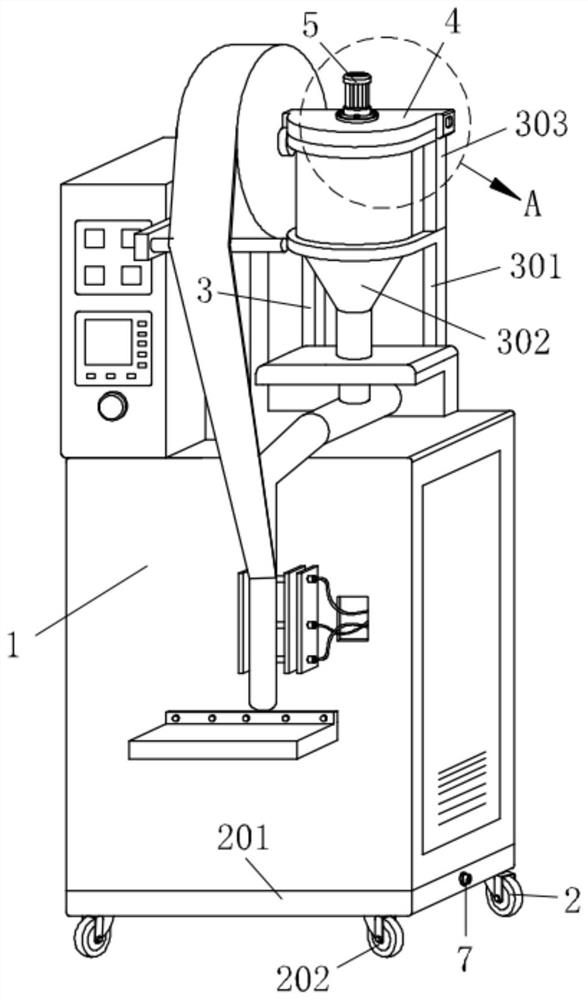

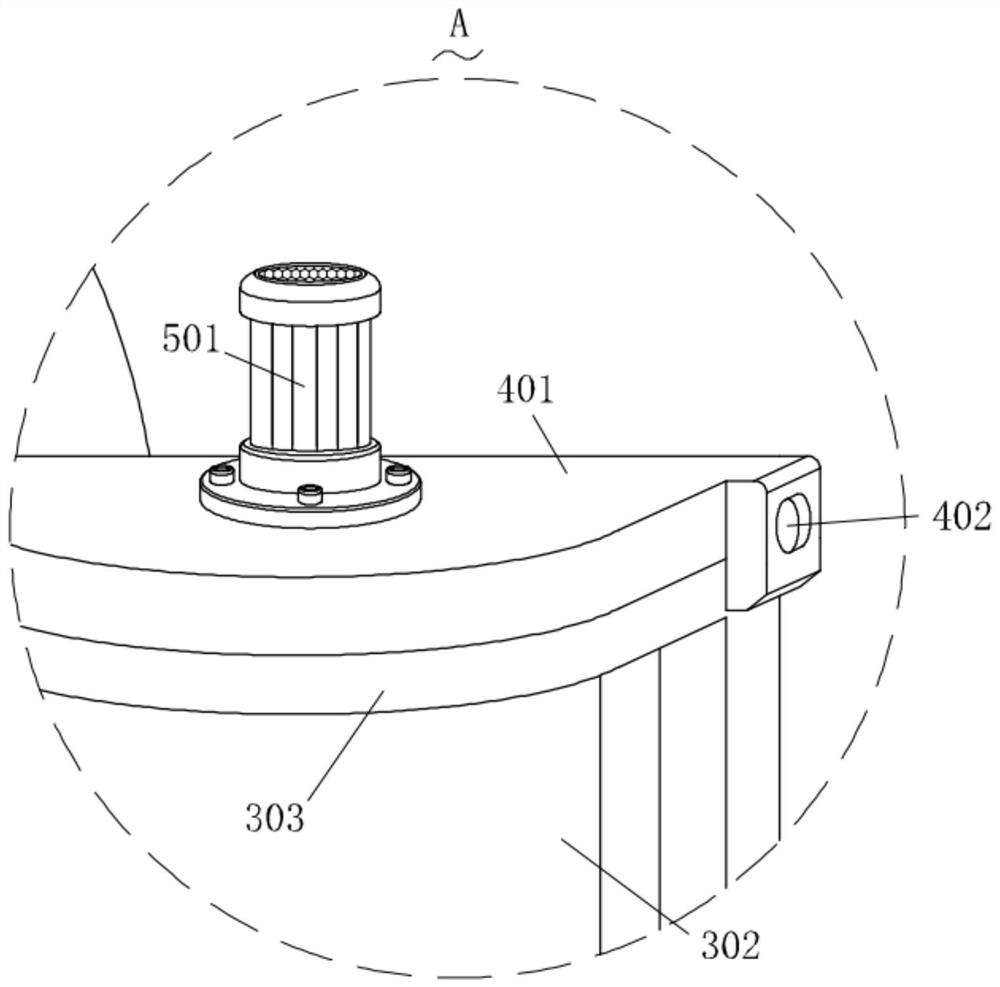

Packaging system for high polymer material production

InactiveCN111994389AIncrease productivityReduce manufacturing costMeasurement of fluid loss/gain rateWrapper twisting/gatheringElectric machineryMolecular materials

The invention discloses a packaging system for high polymer material production, and relates to the technical field of high polymer material production equipment. The packaging system comprises a bottom box and a mounting frame fixedly welded to the top of the bottom box; a control box and a metering tank are fixedly installed at the top of the front surface of the mounting frame through fixing parts in sequence from left to right; a circular conveying mechanism is arranged on the front surface of a mounting plate; a driving motor is fixedly installed at the top of the bottom box and located on the back surface of the mounting plate; and a driving belt wheel is fixedly installed on the outer surface of an output shaft of the driving motor. According to the packaging system for high polymermaterial production, bagging, sealing, air tightness detection, cleaning and automatic discharging can be combined into an integrated system for high polymer material packaging, a large amount of time of production personnel is not needed, and various production devices are adopted for carrying out air tightness detection and cleaning treatment on the packaging bag, so that the production efficiency of high polymer materials is greatly improved, the production cost is low, and the installation site is saved.

Owner:张凯华

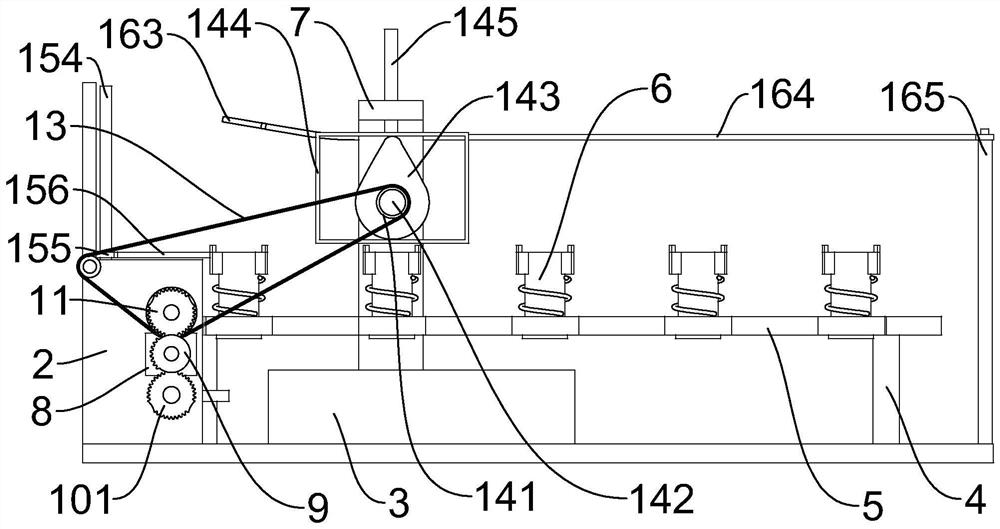

Plant yoghourt packaging machine

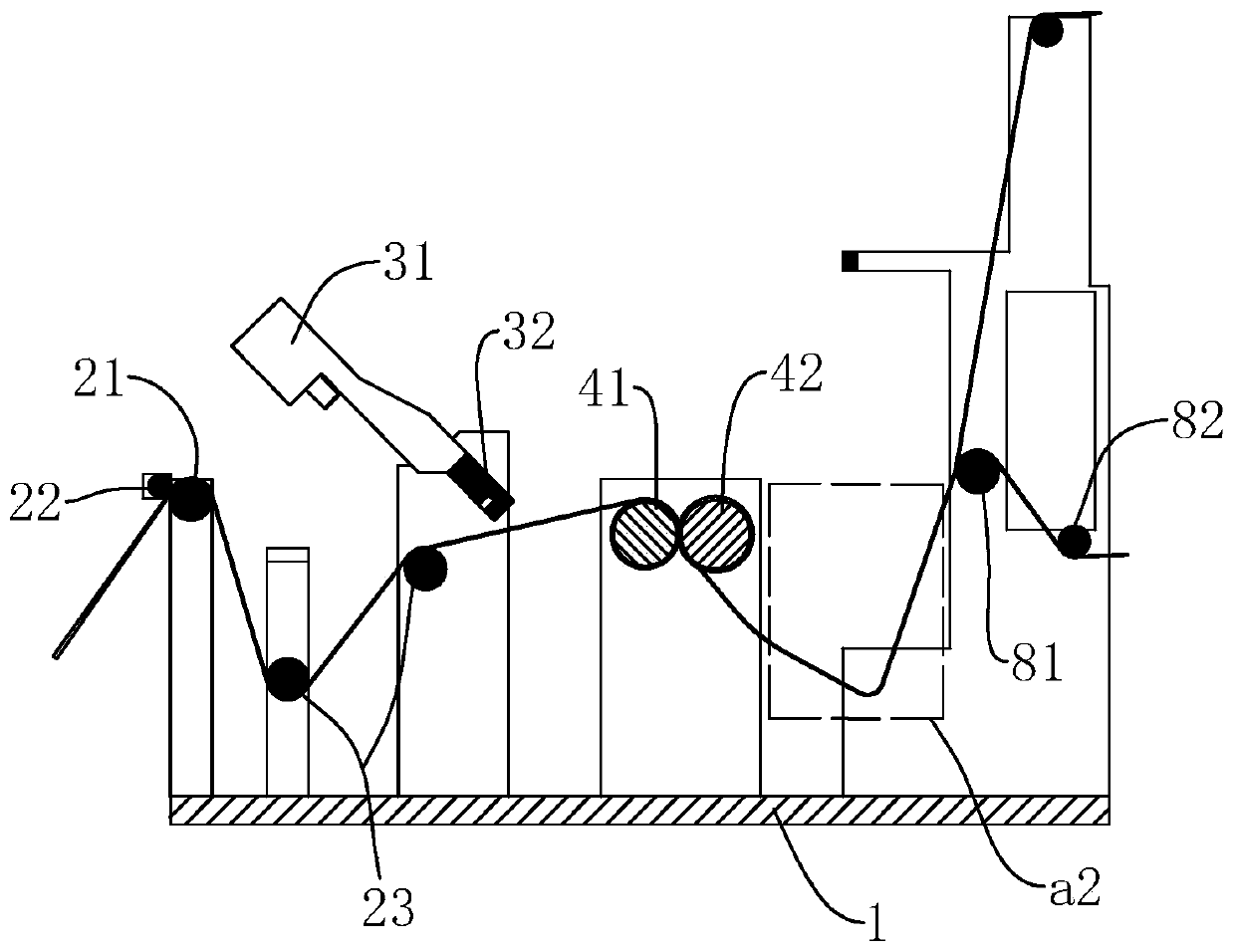

ActiveCN112193529AChange distanceEasy packing jobWrappers shrinkageWrapping material feeding apparatusThin membraneFood packaging

The invention discloses a plant yoghourt packaging machine, and relates to the technical field of food packaging. The plant yoghourt packaging machine comprises a thin film discharging mechanism, andfurther comprises a conveying mechanism, two adjusting mechanisms, a traction mechanism, a cutting mechanism, a transfer mechanism and a heating shrinkage mechanism; the two adjusting mechanisms are symmetrically arranged at two sides of the conveying mechanism, and each adjusting mechanism comprises an upper supporting rod, a lower supporting rod, a first adjusting assembly and a second adjustingassembly, wherein the second adjusting assembly is arranged on the first adjusting assembly, the upper supporting rod is fixedly connected with the second adjusting assembly, and the lower supportingrod is fixedly connected with the first adjusting assembly; and the cutting mechanism is arranged at the upper end of the transferring mechanism; and one end of the heating shrinkage mechanism is adjacent to the transfer mechanism. According to the plant yoghourt packaging machine, through cooperative work of the first adjusting assemblies and the second adjusting assemblies, yoghourt packaging cups of different sizes can be packaged and processed, and the applicability of the plant yoghourt packaging machine is improved.

Owner:恒源生物科技有限公司

Piece arranging device for baby diaper production

PendingCN112690950AEasy to watchEasy to take outAbsorbent padsBaby linensElectric machineryEngineering

The invention discloses a piece arranging device for baby diaper production. The device comprises a box body, a piece arranging box and a conveying belt, wherein a motor is fixedly mounted on the surface of the box body, a second bearing is movably mounted in the box body on one side of the first bearing, a reflecting plate is fixedly mounted at the top of the box body at the other end of the conveying belt, an inductive probe is fixedly mounted at the top of the box body at one end of the conveying belt, a counter is fixedly mounted on the surface of the box body at the bottom of the inductive probe, first electric push rods are fixedly mounted on the surfaces of the two sides of the piece arranging box, and sliding rails are fixedly mounted on the two sides of the interior of the piece arranging box at the bottoms of the first electric push rods. By arranging the counter, the number of paper diapers needing to be subjected to piece arrangement and conveyed by the conveying belt can be recorded, checking by workers is facilitated, extrusion and piece arrangement work can be automatically conducted, and the paper diapers subjected to piece arrangement can be conveniently taken out by the workers to be subjected to packaging work.

Owner:石蕊

A gift box forming packaging mold and its working method

ActiveCN111231417BAvoid irregular dischargeReduce labor intensityPaper-makingBox making operationsHydraulic cylinderEngineering

The invention discloses a gift box forming and packaging mold, which comprises a bottom box and a workbench. A workbench is arranged on the top of the bottom box, and a bottom plate is arranged above one end of the workbench. Two fourth hydraulic cylinders are used to control the internal The fourth hydraulic rod moves to the outside of the cylinder, so that the two horizontal inserts are located on the other two sides of the lifting platform. When the lifting platform descends, the wrapping paper on the outside of the gift box is erected and covered around the gift box. On the gift box, control the movement of the two horizontal inserting plates again so that the wrapping paper is bent and covers the top surface of the gift box, and the push plate slides along the first sliding groove, so that the rectangle surrounded by the four push plates gradually decreases , and finally resist the surroundings of the gift box on the lifting platform to realize the shape bonding and fixing of the gift box, complete the forming and packaging of the gift box, and improve work efficiency. The gift box is more beautiful.

Owner:韶关国正精密制造科技有限公司

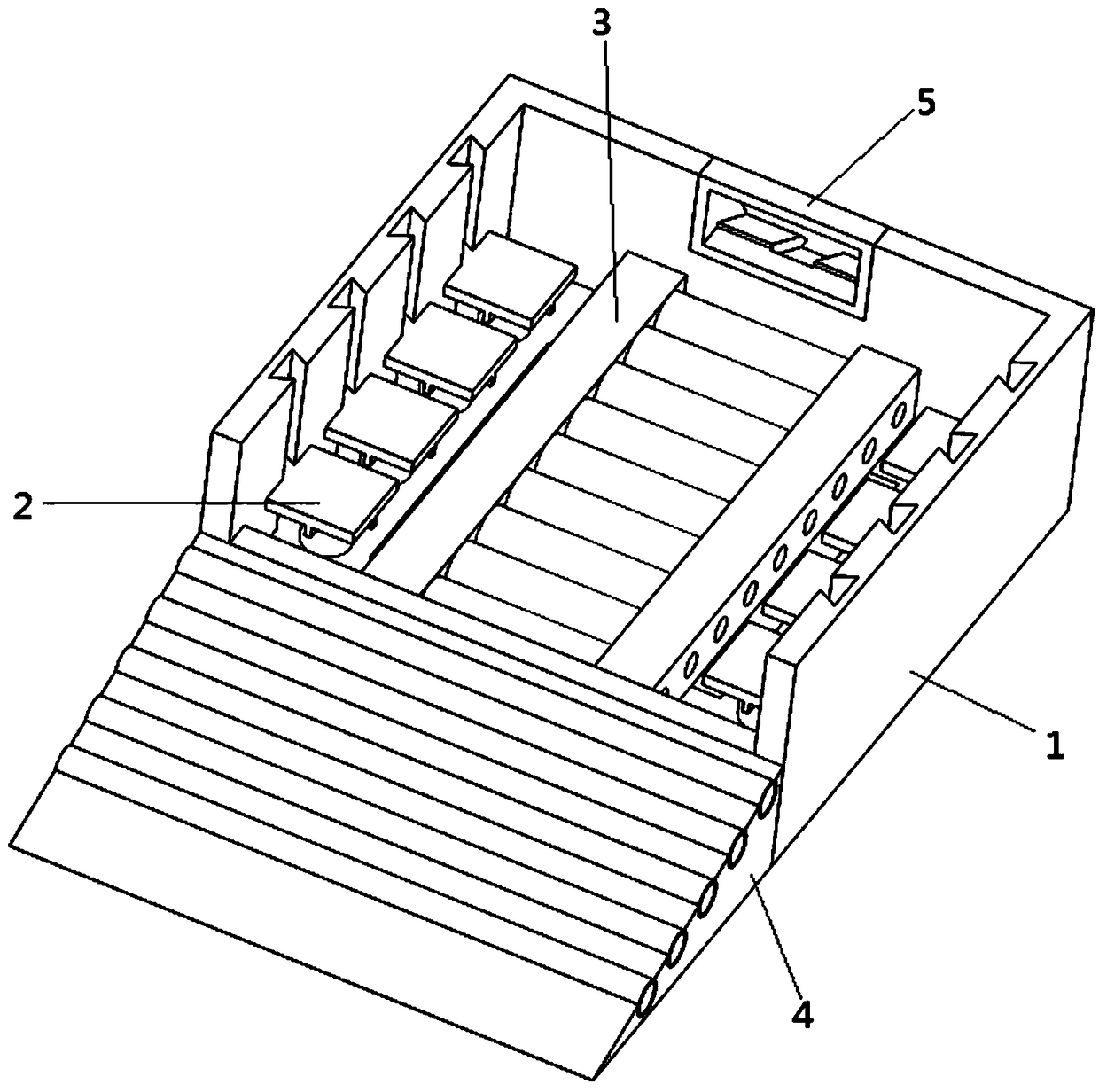

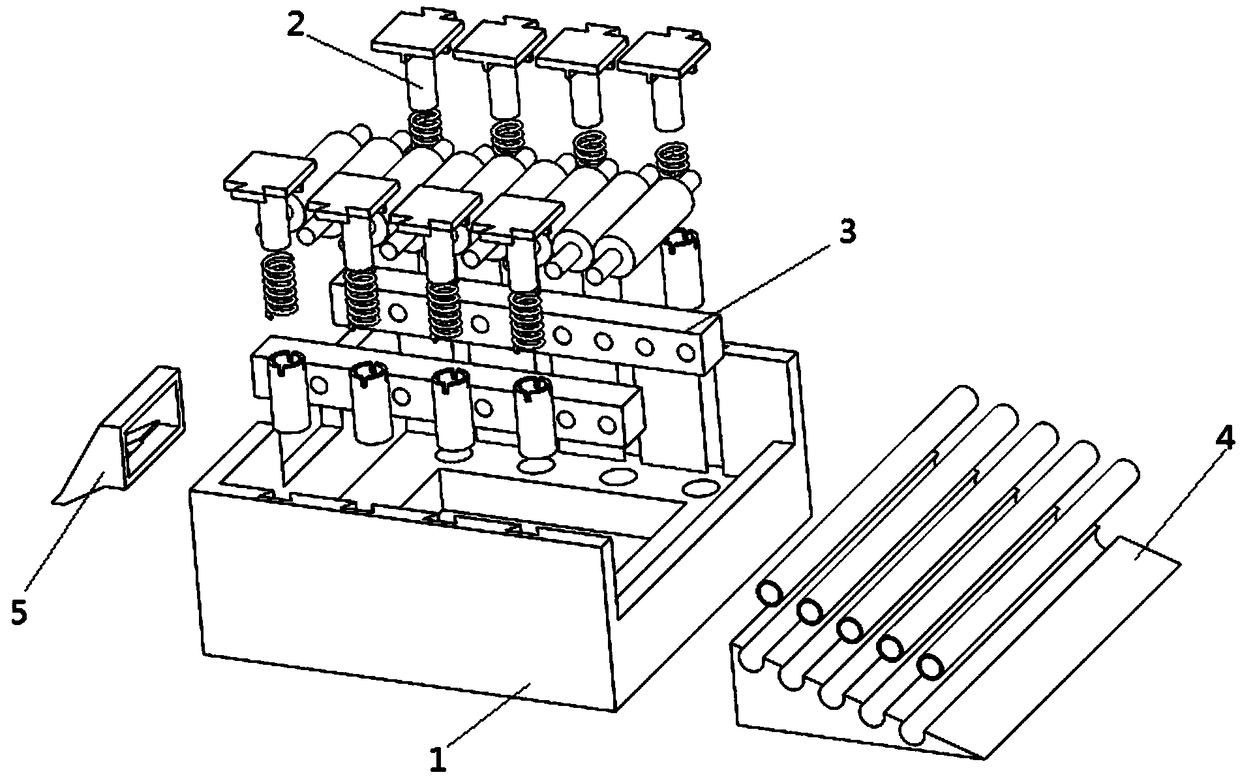

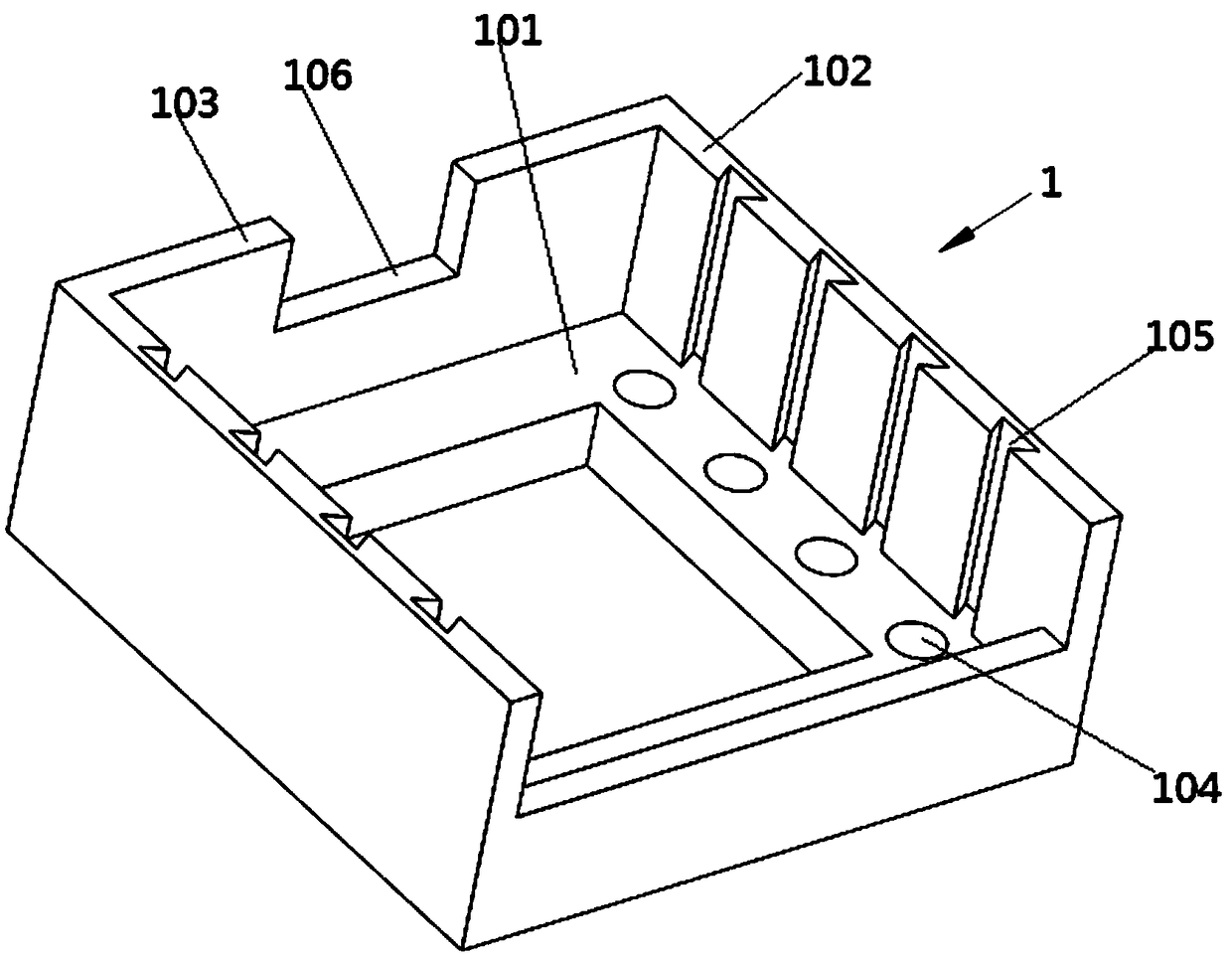

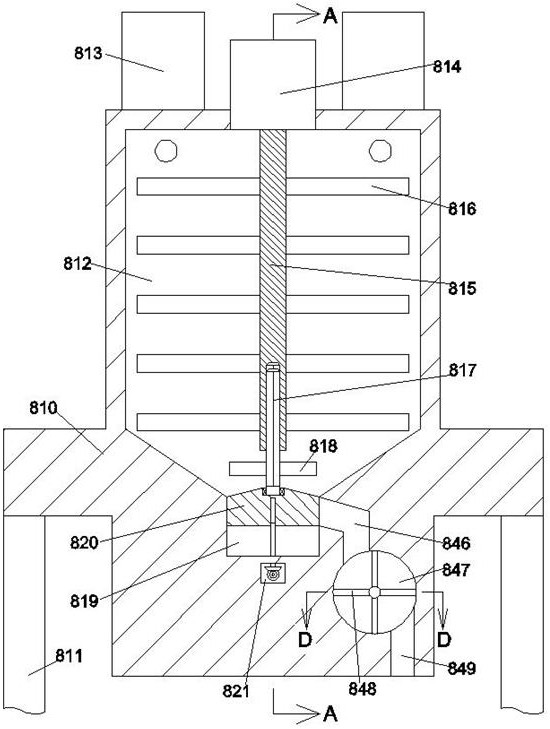

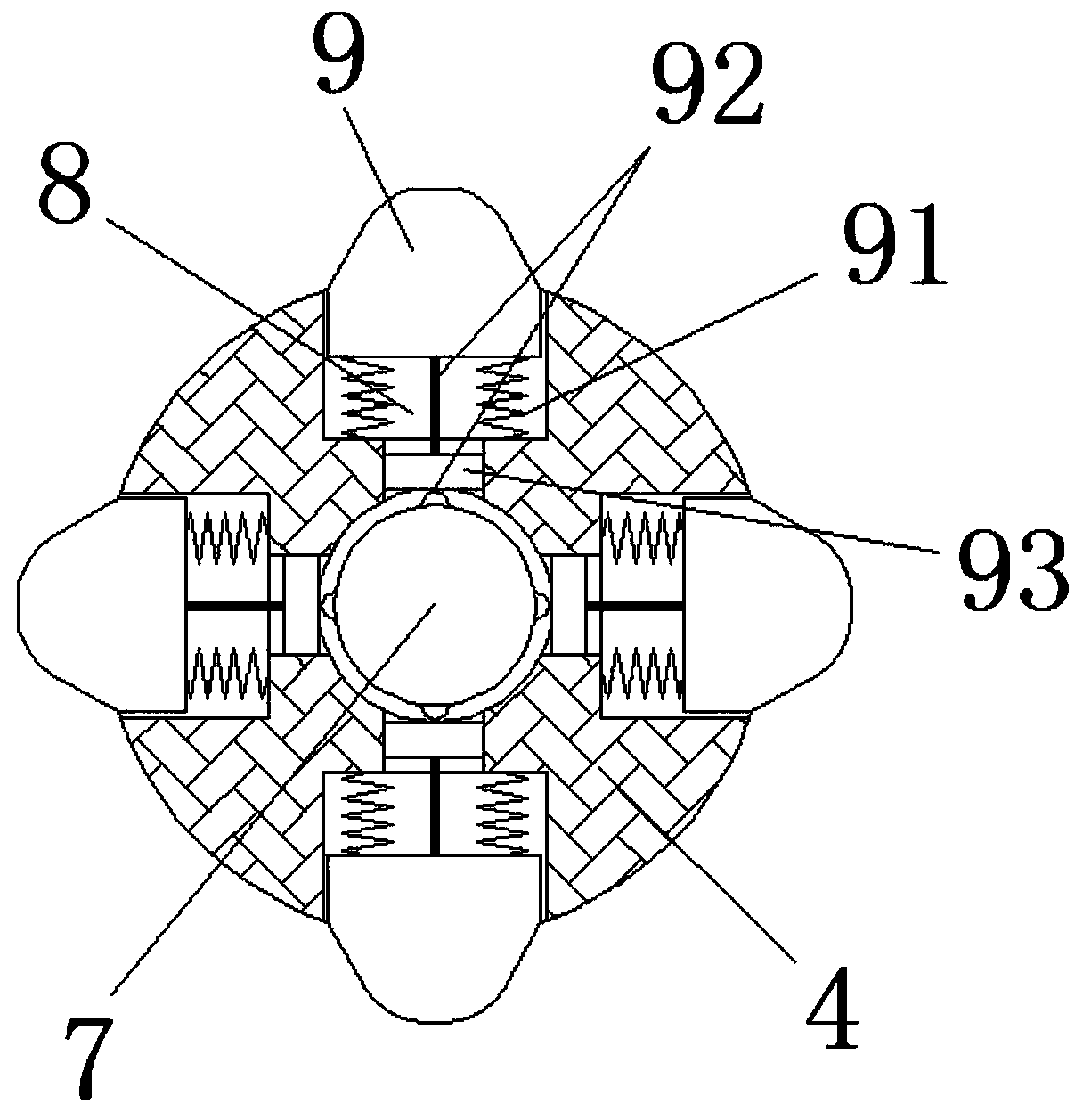

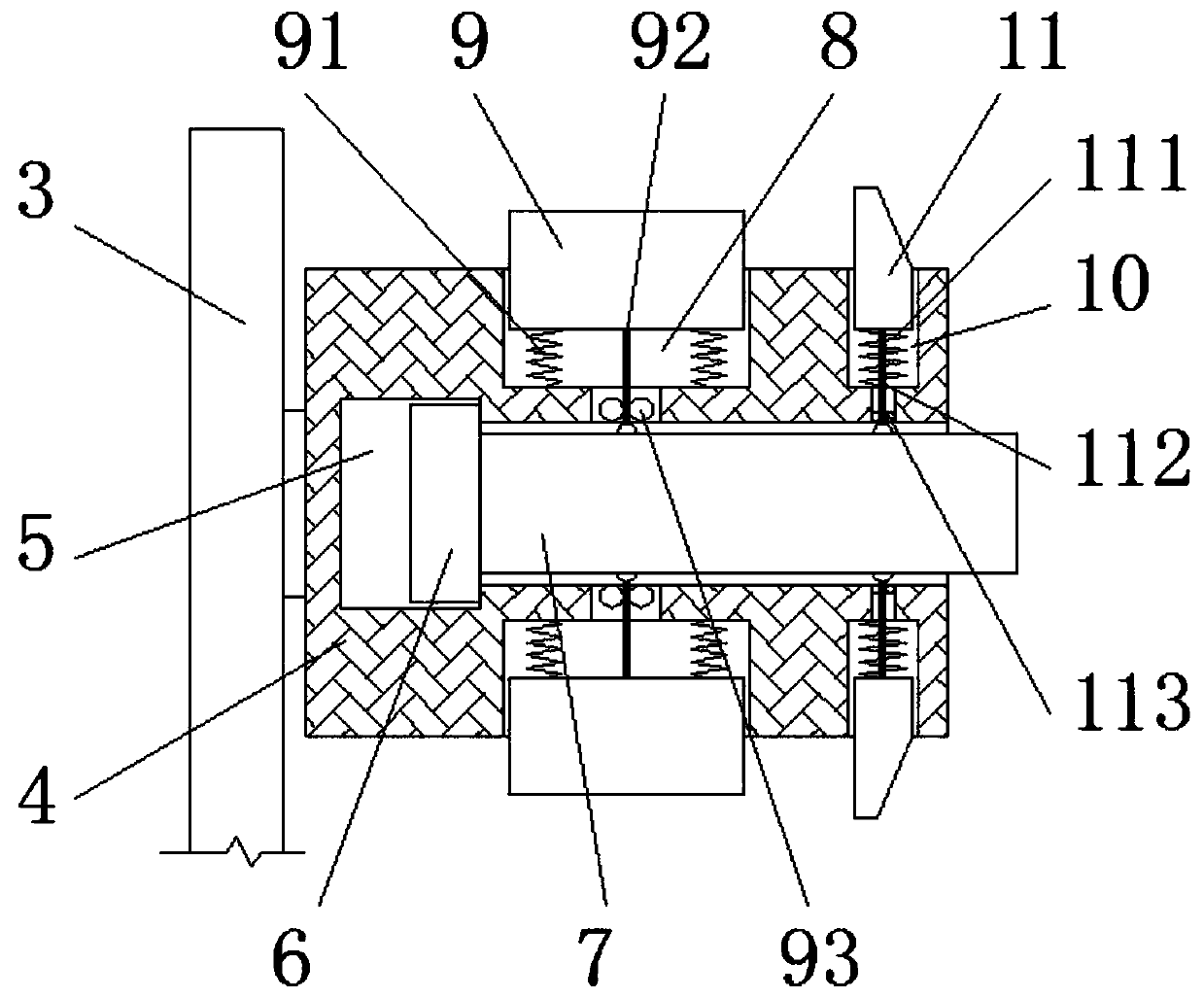

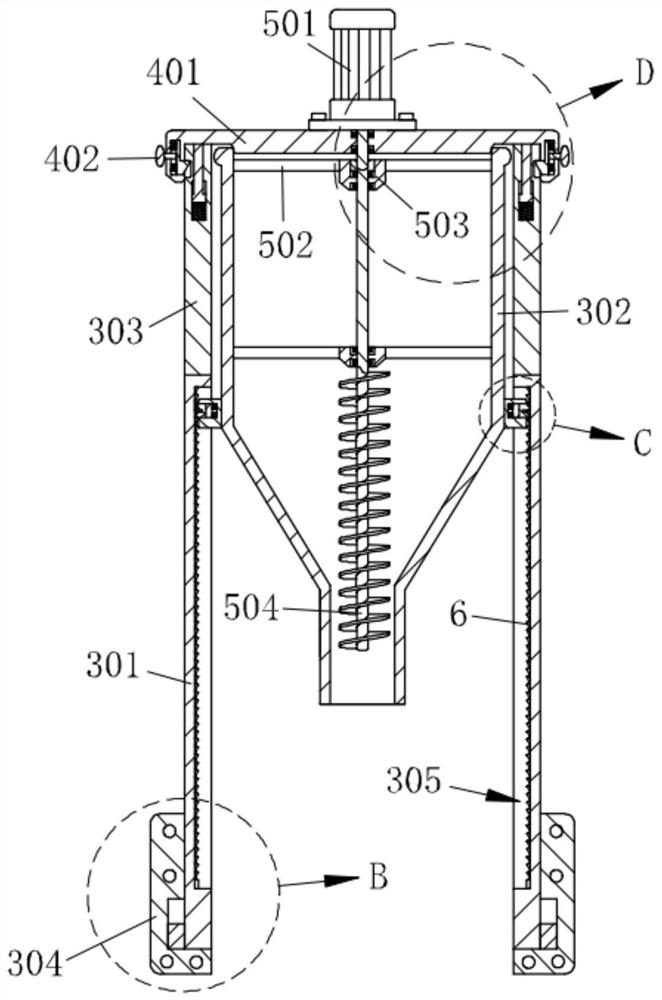

A support device for a diode molding machine

ActiveCN107813533BProtection from damageAvoid damageMachine framesSemiconductor/solid-state device manufacturingMolding machineEngineering

The invention discloses a supporting device of a diode mould pressing forming machine. The supporting device comprises a base, four buffer mechanisms distributed linearly are installed on the left side and the right side of the base, two rolling supporting mechanisms are installed in the middle of the base, a slope platform is installed on the front side of the base, and a discharging hopper is installed on the rear side of the base. According to the supporting device, through the design of cooperation of the buffer mechanisms and the base, the diode mould pressing forming machine is firmly fixed and effectively protected against corrosion, diodes are protected against damage by static electricity, buffer supporting is formed when the forming machine works, and the problem that diodes aredamaged by static electricity and vibration is solved; and meanwhile, through the design of the discharging hopper, cores of diodes obtained after mold pressing roll down along a discharging groove, orderly and sequential discharging can be conducted, irregular collision among diodes is avoided, and the problem that diodes are difficult to collect and sort when discharged is solved.

Owner:ANHUI MINGYANG ELECTRONICS

Preparation process of flame-retardant antibacterial easily-degradable plastic master batch

The invention discloses a preparation process of flame-retardant antibacterial easily-degradable plastic master batch. The preparation process comprises the following steps that raw materials are fedinto flame-retardant antibacterial plastic master batch preparation equipment through a raw material injection port; spiral conveying rotating shafts in the flame-retardant antibacterial plastic master batch preparation equipment rotate, so that added materials enter a mixing chamber, and the raw materials are stirred and mixed through rotation of a first blade and a second blade; the left spiralconveying rotating shaft and the right spiral conveying rotating shaft are controlled to rotate at the same time or the spiral conveying rotating shaft on one side is controlled to rotate, and different added material control operations are chosen; and after the plastic master batch in the mixing chamber is mixed, a lifting sealing sliding block is moved downwards, and the mixed plastic master batch is discharged in a quantitative control mode through a material distributing wheel in a quantitative material distributing chamber. The preparation process of the flame-retardant antibacterial easily-degradable plastic master batch improves the mixing uniformity of plastic particles, improves the quality of plastic products, can reduce the labor intensity of operators, and improves the production efficiency.

Owner:刘锦刚

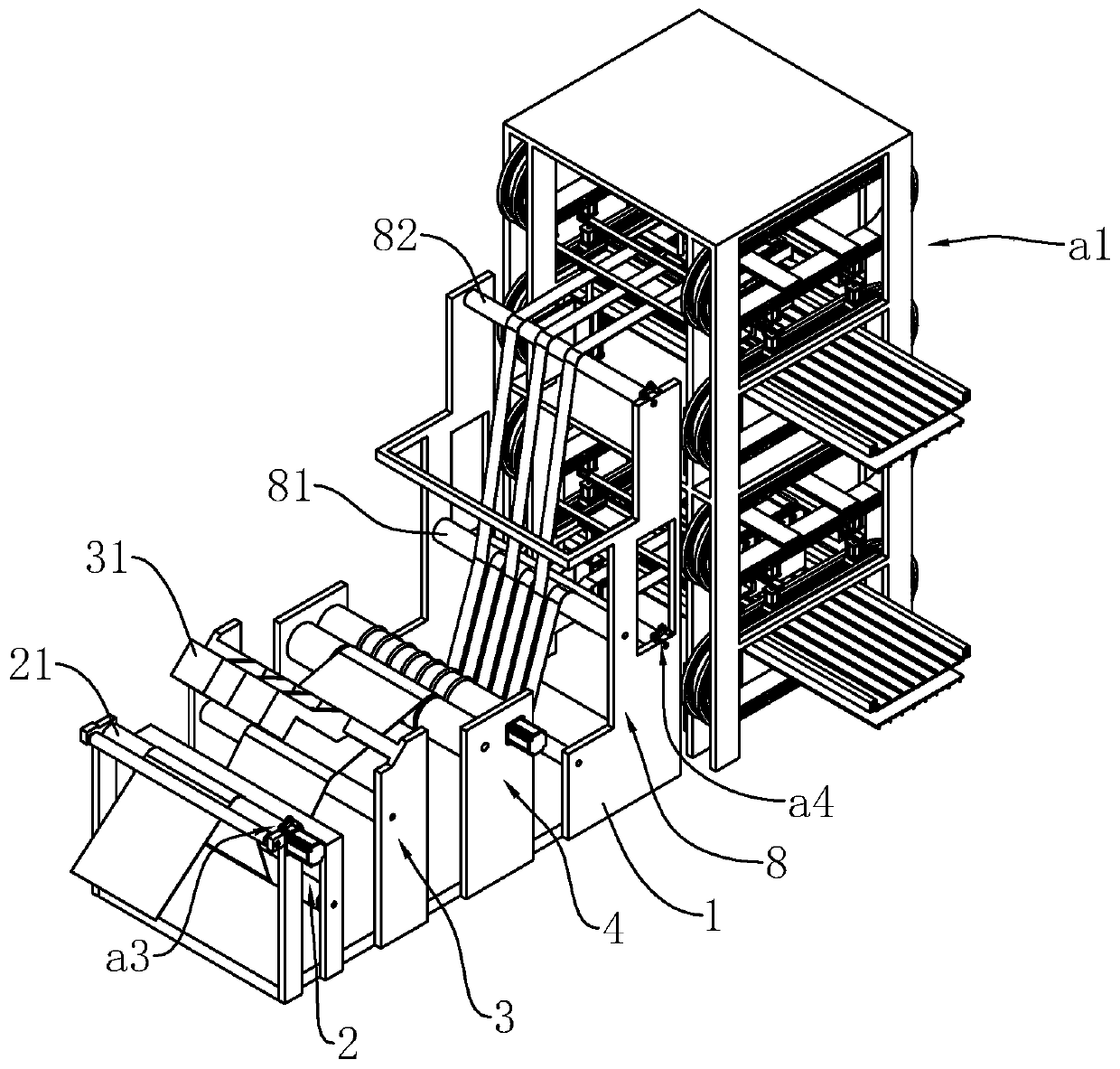

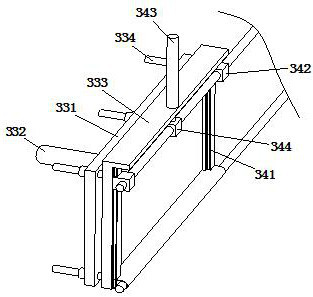

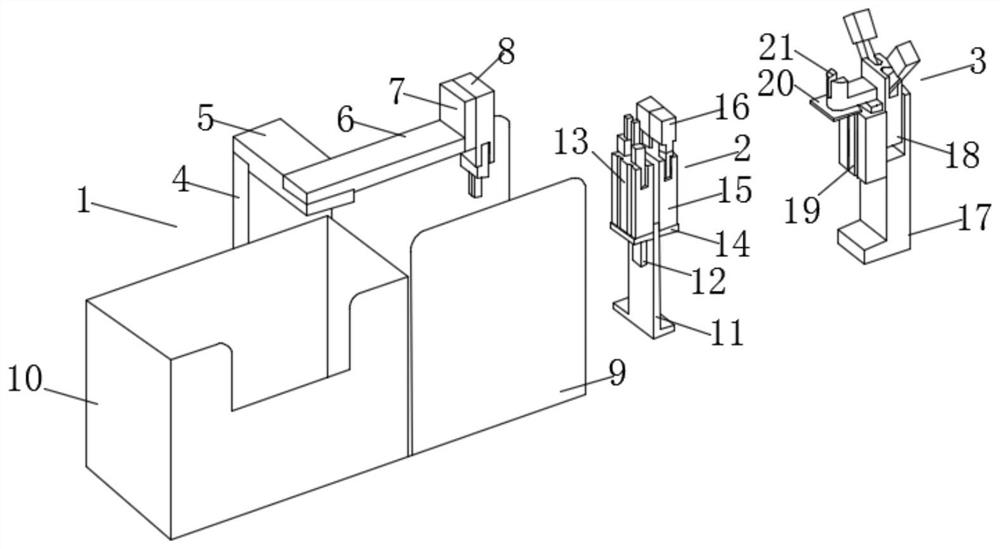

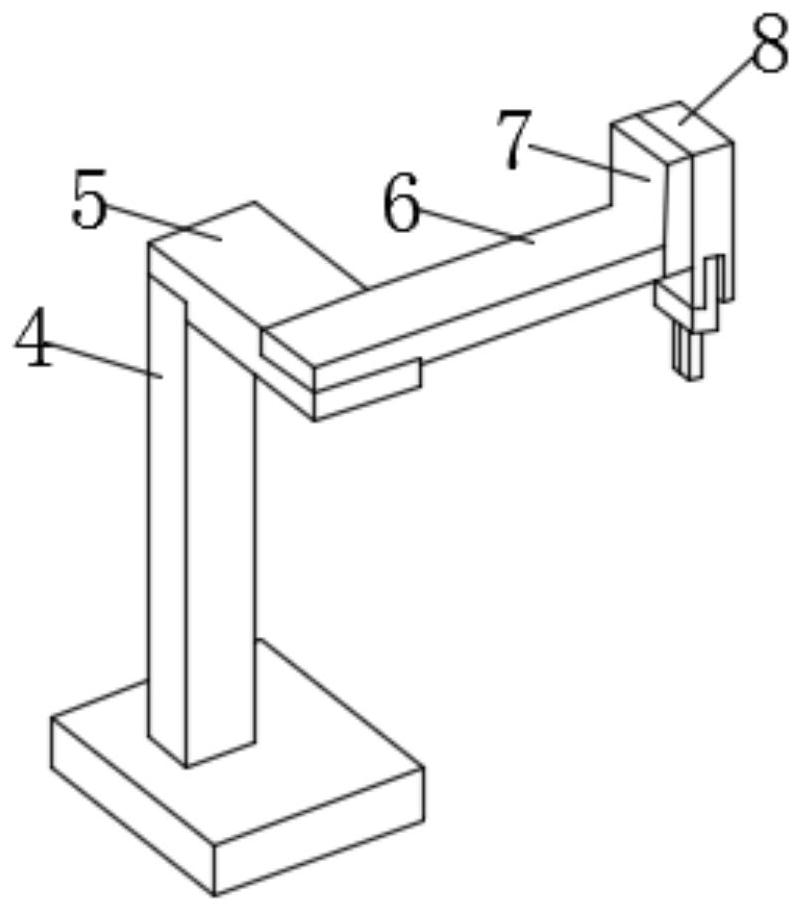

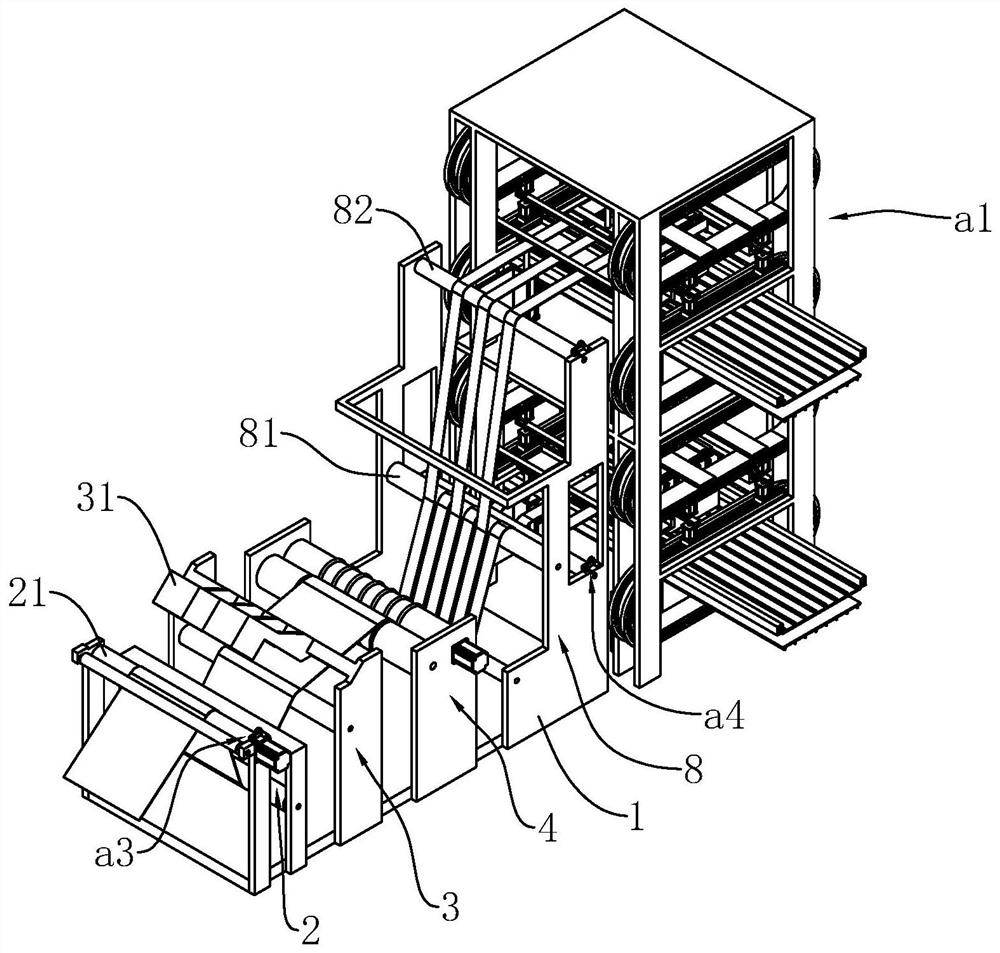

Sorting and sorting feeding structure and working method of double-line bag

ActiveCN110217430BImprove packaging efficiencyEffective combing effectPackagingDual coilStructural engineering

The invention discloses an arranging classifying feeding structure of dual coils and a work method thereof. The structure comprises a receiving mechanism, a wire arranging mechanism and a wire conveying mechanism; the receiving mechanism is composed of a first fixed supporting plate, a first transverse plate, a second transverse plate, a fixed side plate, a taking arranging finger clamp, a good product frame and a bad product frame, the first transverse plate is fixedly mounted on a top fixed screw of the first fixed supporting plate, the end, away from the first fixed supporting plate, of thetop of the first transverse plate is fixedly provided with the second transverse plate through a screw, two sets of front and back wires of the dual coils can be effectively carded, after the dual coil finished products are in order, packaging work is facilitated, the packaging work efficiency of the dual-coil product can be greatly improved, the condition that the products are in disorder, and during packaging, the products are damaged is avoided, and good products and bad products can be automatically separated to be put into two different material frames.

Owner:ZHONGSHAN ZHANHUI ELECTRONICS EQUIP

Packagable frozen chicken and duck dicing device and packaging method

InactiveCN111543466AImprove cooling effectEasy to moveMeat/fish preservation by freezing/coolingPoultry transferring/conveying devicesBiotechnologyEngineering

The invention discloses a packagable frozen chicken and duck dicing device and relates to the technical field of frozen chicken and duck dicing and packaging. The device comprises a machine body; a pressing mechanism mounted at the top end of the machine body; a supporting frame is arranged on the inner side of the pressing mechanism; a first electric push rod is connected to one side of the supporting frame and connected with the supporting frame through a connecting shaft; and a pressing frame is connected to the top end of the first electric push rod. The beneficial effects of the inventionare that: according to the packagable frozen chicken and duck dicing device, through the arrangement of a cooling mechanism composed of a water tank, a water pump and a water pipe, people can start the water pump, so that a cooling liquid in the water tank can conveniently flow upwards in a spiral retrograde manner through the water pipe; the cooling time of a fixing cylinder is prolonged, the fixing cylinder can be conveniently cooled in a targeted mode, electric energy loss is reduced, and the situation that the subsequent packaging speed of chicken and duck blocks is reduced due to the fact that ice freezing occurs between the chicken and duck blocks and the conveyor belt due to the fact that the temperature below the interior of the device is too low is avoided.

Owner:SHENGSHIYAOLAN SHENZHEN TECH CO LTD

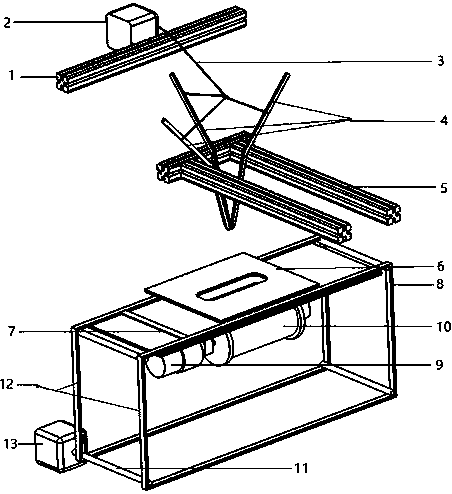

Novel fruit bagging and bag cutting device

The invention discloses a novel fruit bagging and bag cutting device. The device comprises a bagging motor support, a bagging motor, drawing lines, bagging movable rods, a bagging movable rod support,a rectangular bag feeding plate, a cutting wire, a conveying belt, a bag feeding motor support, a bag feeding motor, transmission idler wheels, a conveying belt motor idler wheel, a conveying belt and a conveying belt motor, wherein the bagging motor is arranged in the middle of the bagging motor support, the drawing lines are connected to the bagging motor support, the three bagging movable rodsare respectively fixed in the bagging movable rod support and are respectively connected with the bagging motor through the drawing lines, the rectangular bag feeding plate is fixed right above the conveying belt, the two transmission idler wheels are arranged under the conveying belt, one transmission idler wheel is connected with the bag feeding motor, the conveying belt motor and the conveyingbelt motor idler wheel are connected, and the cutting wire is fixed to one end of the conveying belt. The device has the advantages of simple structure, convenience in use and ability in solving a series of problems that automation of existing manual fruit bagging and bag cutting is not achieved and the like.

Owner:NORTHWEST A & F UNIV

A cutting machine for automatic processing of defective materials

The invention discloses a slitting machine capable of automatically processing defective materials. According to the technical scheme, the slitting machine comprises a rack, wherein an unreeling mechanism, a detection mechanism, a longitudinal cutting mechanism, a feeding mechanism, a transverse cutting mechanism, a sorting mechanism and a receiving mechanism are sequentially arranged on the rackin the material conveying direction; the detection mechanism comprises a CCD camera and a detection light source; the sorting mechanism is arranged between the transverse cutting mechanism and the receiving mechanism; and the receiving mechanism comprises a waste frame and a conveying belt. The CCD camera collects specific positions of defects existing on the materials, and a plurality of materialblocks are formed after the materials are sequentially longitudinally cut and transversely cut; and the material blocks with the pattern defects are fed into the waste frame according to the data provided by the CCD camera, the qualified material blocks are placed on the conveyor belt to be conveyed to a subsequent process flow for cigarette production, and the part with the defect patterns in the cigarette tipping paper can be automatically cut off.

Owner:湖北烟草民意纸业有限公司

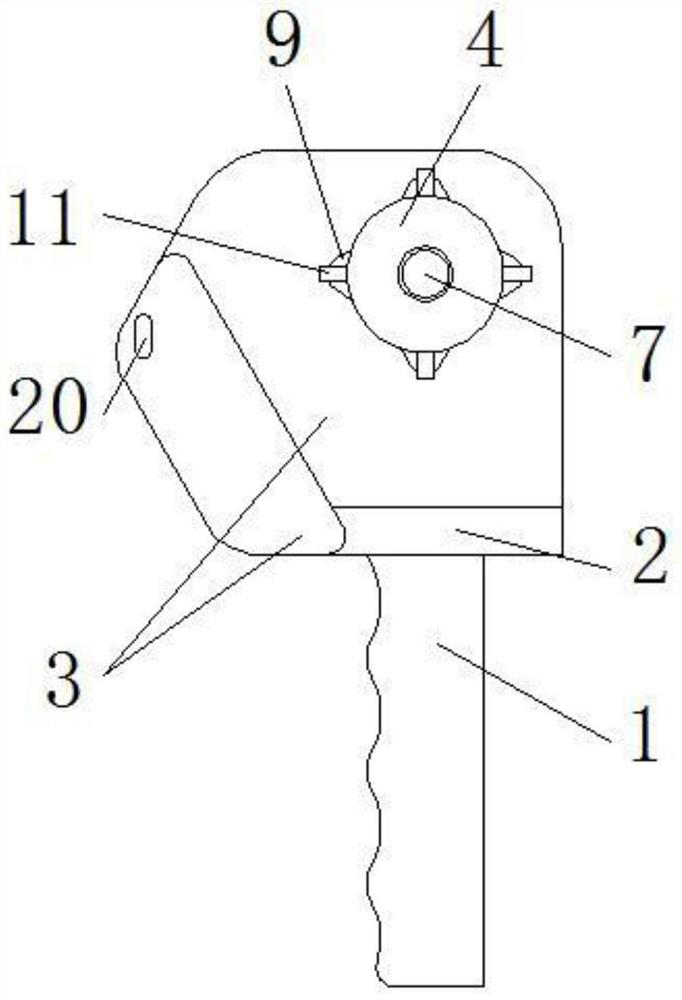

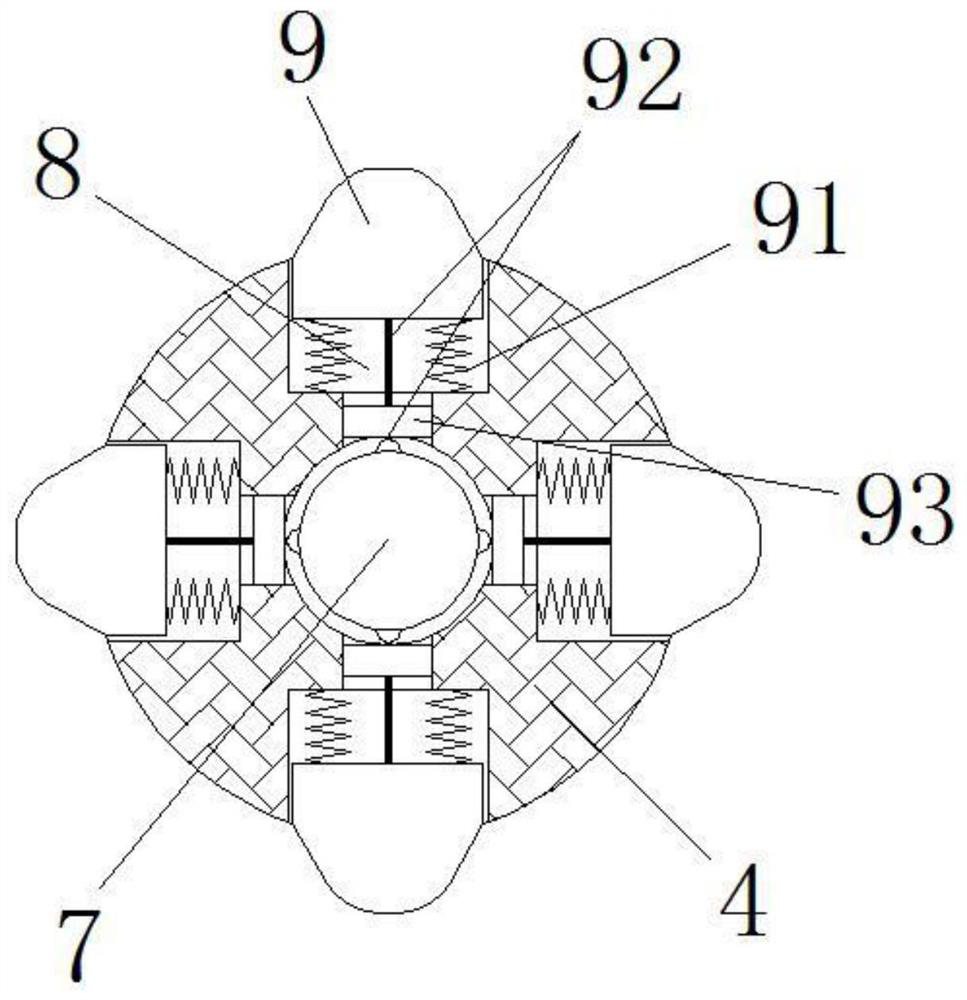

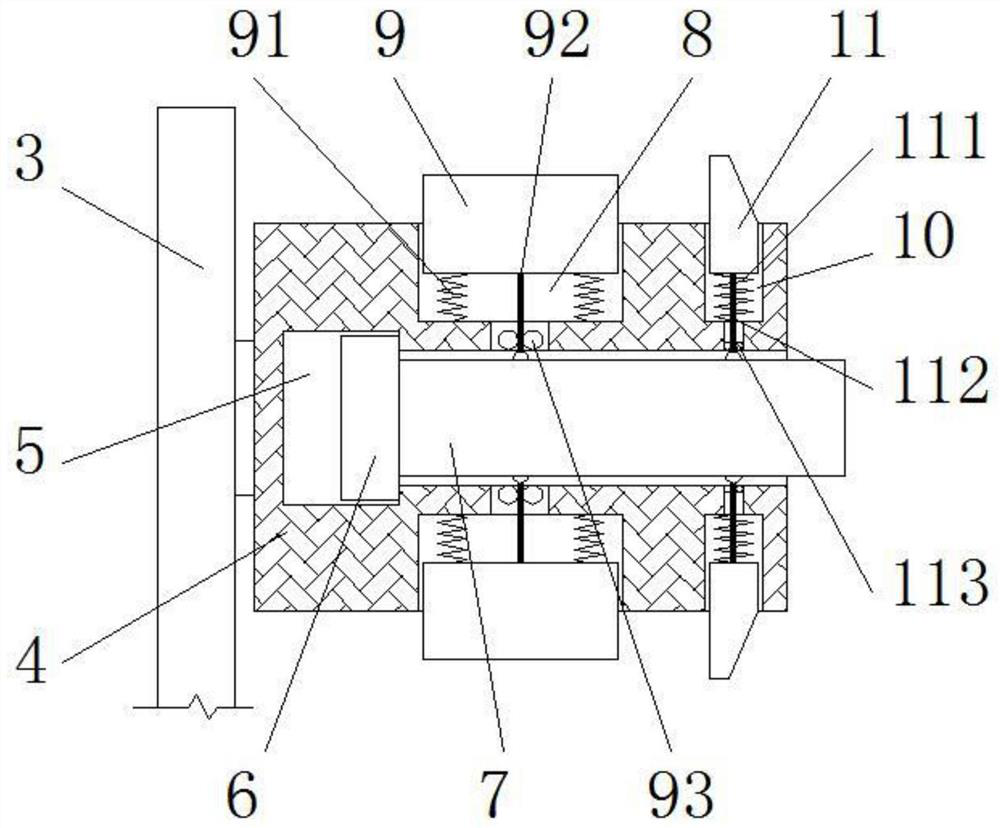

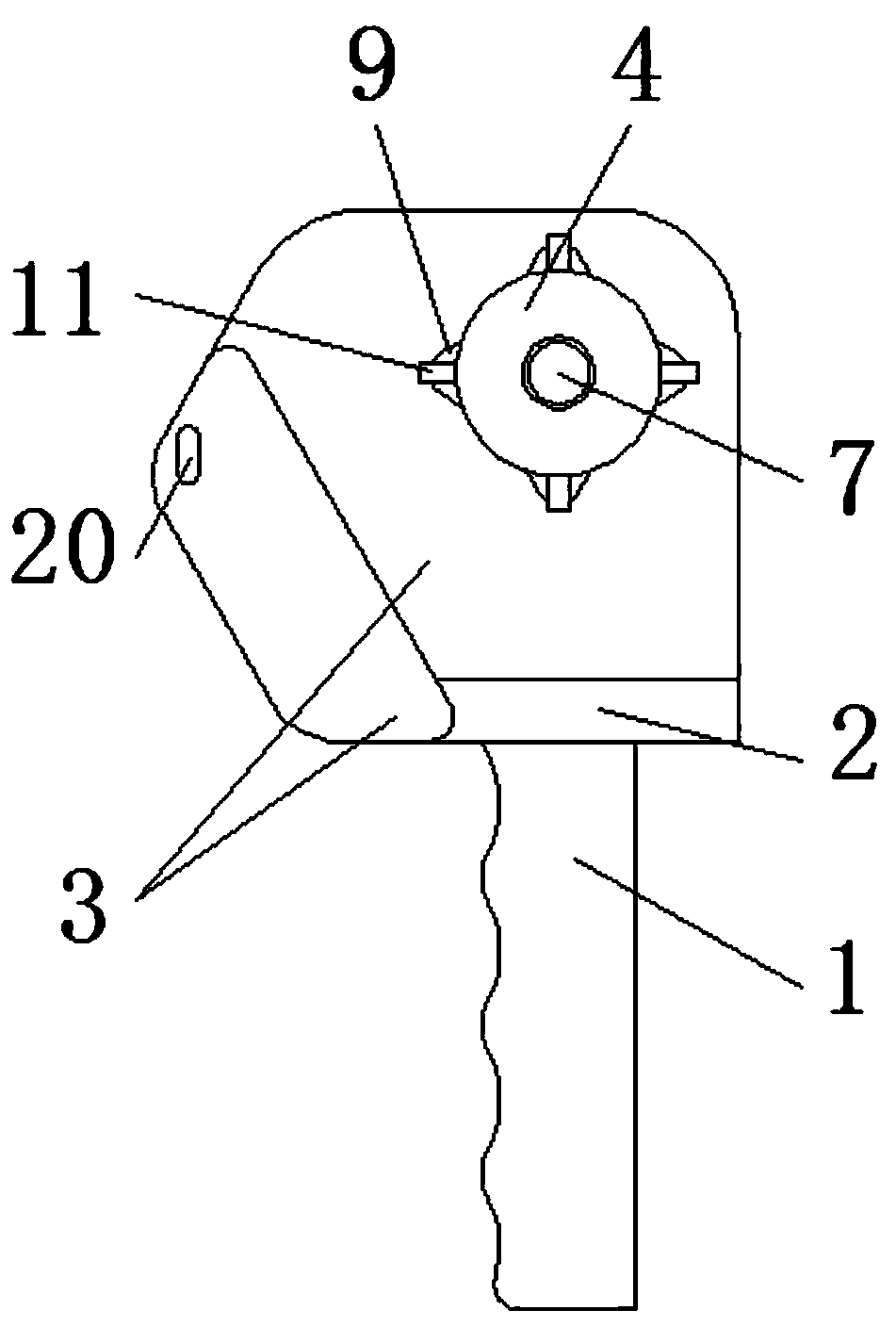

A baler for logistics packaging with anti-collision and convenient film replacement

ActiveCN110395451BEasy to replaceEasy to installWrapper twisting/gatheringArticle deliveryLogistics managementStructural engineering

The invention discloses a packing machine for logistics packaging, which is anti-collision and convenient for film replacement, comprising a handle, a fixing plate and a cutter. The outer frame, and the bearing on the supporting outer frame is connected with a rotating shaft, the interior of the rotating shaft is provided with a limit groove, and the interior of the limit groove is installed with a limit plate, the front surface of the limit plate is fixedly installed with a push shaft, and the push shaft is installed. The shaft passes through the rotating shaft, the outer surface of the rotating shaft is respectively provided with a first receiving groove and a second receiving groove, and a pressing plate is installed inside the first receiving groove. The baler for logistics packaging, which is anti-collision and convenient for film replacement, can be connected with the first connecting groove through the straight plate when the cutter needs to be protected later, so that the positions of the connecting plate and the protection plate are fixed, which is convenient for The protective plate protects the tool and reduces the chance of bumping.

Owner:山西夯达科技供应链有限公司

Anti-collision packager for logistics packaging convenient for film replacement

ActiveCN110395451APrevent falling offEasy to protectWrapper twisting/gatheringArticle deliveryEngineeringLogistics management

The invention discloses an anti-collision packager for logistics packaging convenient for film replacement, comprising a handle, a fixing plate and a cutter, wherein a fixing plate is fixedly mountedon the top surface of the handle, a support outer frame is fixedly mounted on the outer surface of the fixing plate and is connected with a rotating shaft through a bearing, the rotating shaft is internally provided with a limiting slot which is internally provided with a limiting plate, a pushing shaft is fixedly mounted on the front surface of the limiting plate and passes through the rotating shaft, a first containing groove and a second containing groove are respectively formed in the outer surface of the rotating shaft, and a pressing plate is installed inside the first containing groove.According to the anti-collision packager, when needing to be protected, the cutter can be engaged with a first connecting groove by a straight plate, so that the positions of a connecting plate and aprotective plate are fixed, which facilitates the protection of the cutter by the protective plate and reduces the chance of collision.

Owner:嘉兴考普诺机械科技有限公司

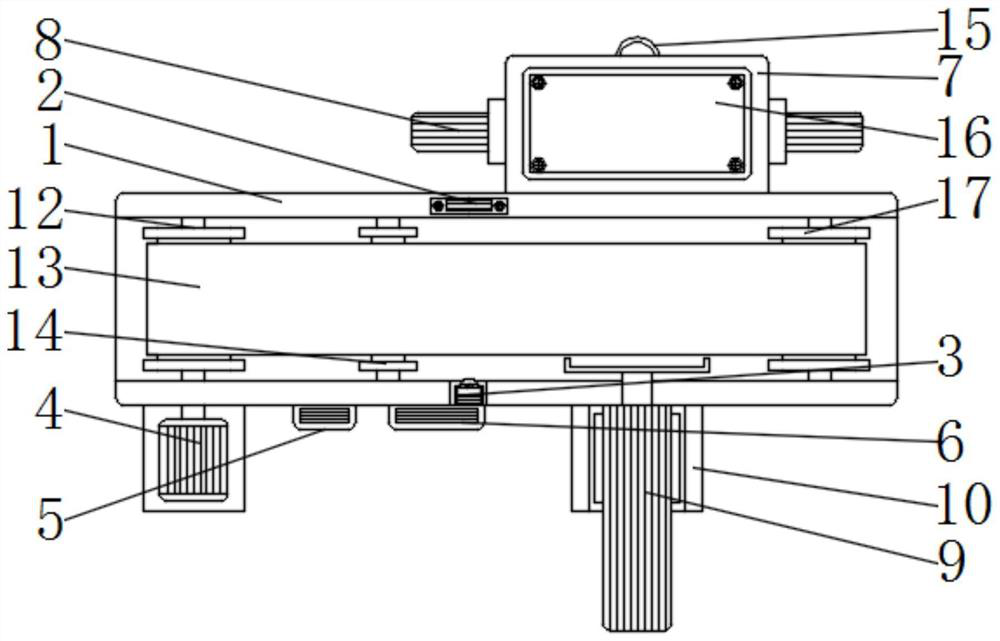

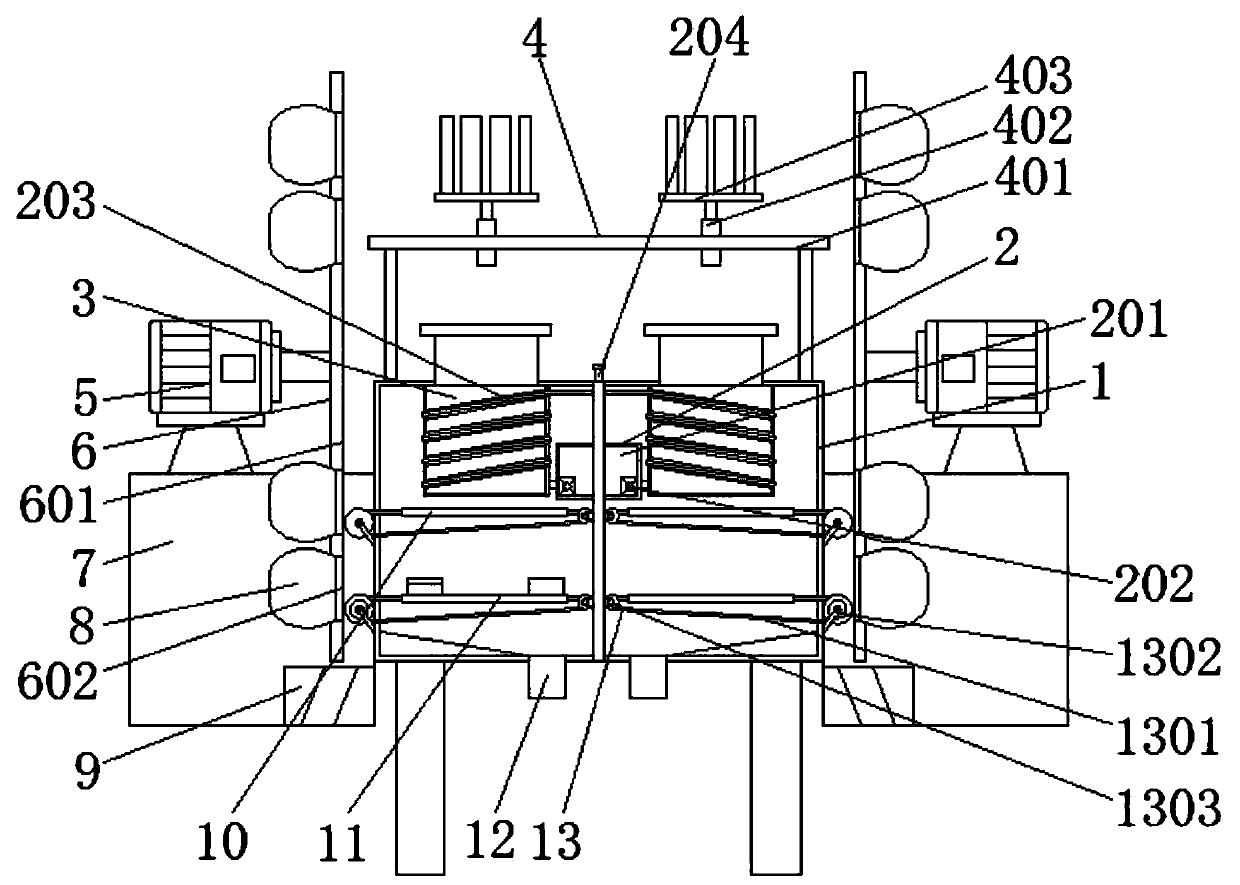

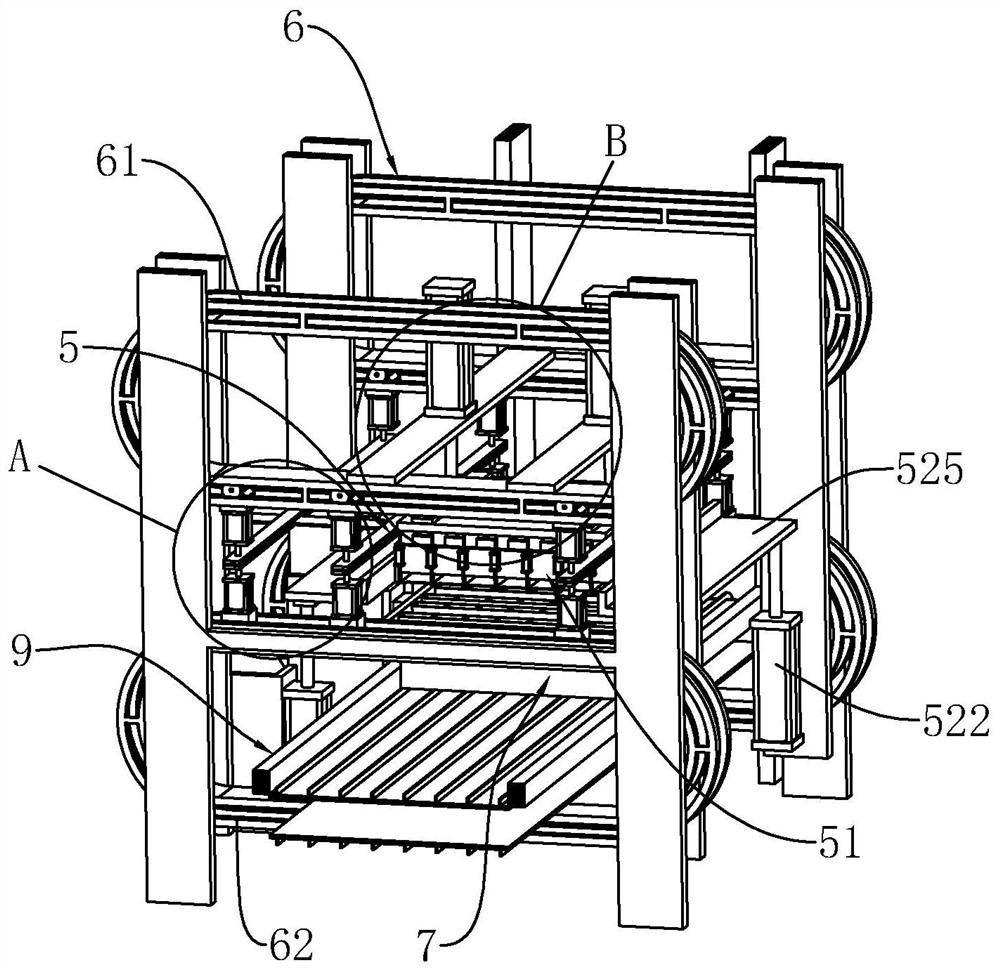

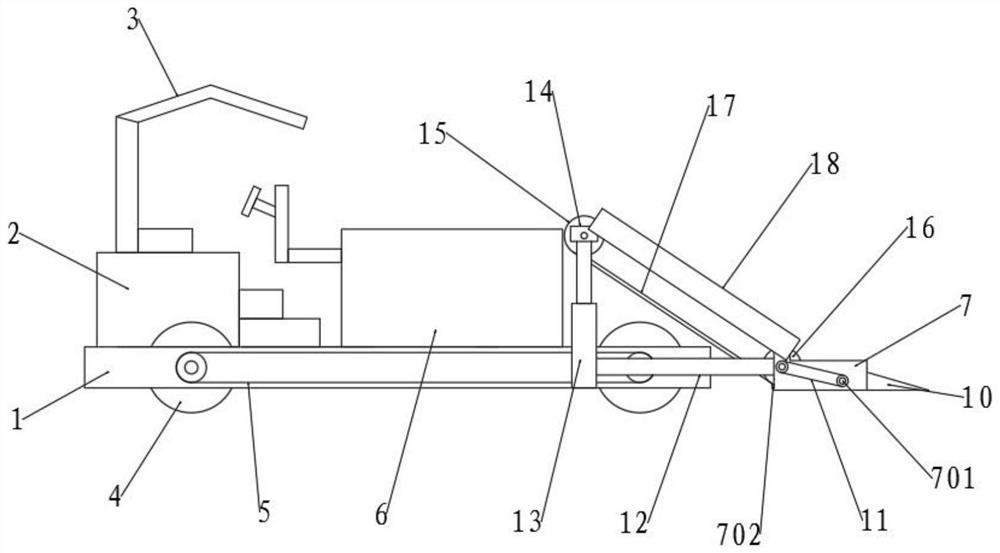

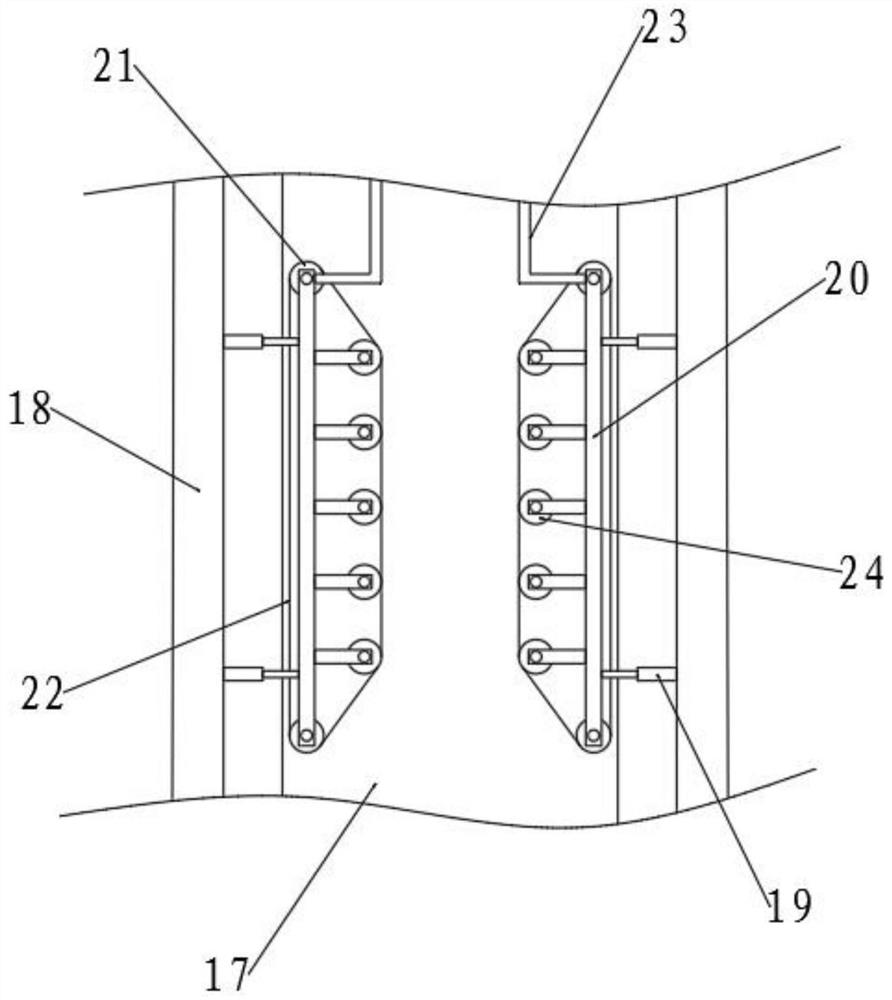

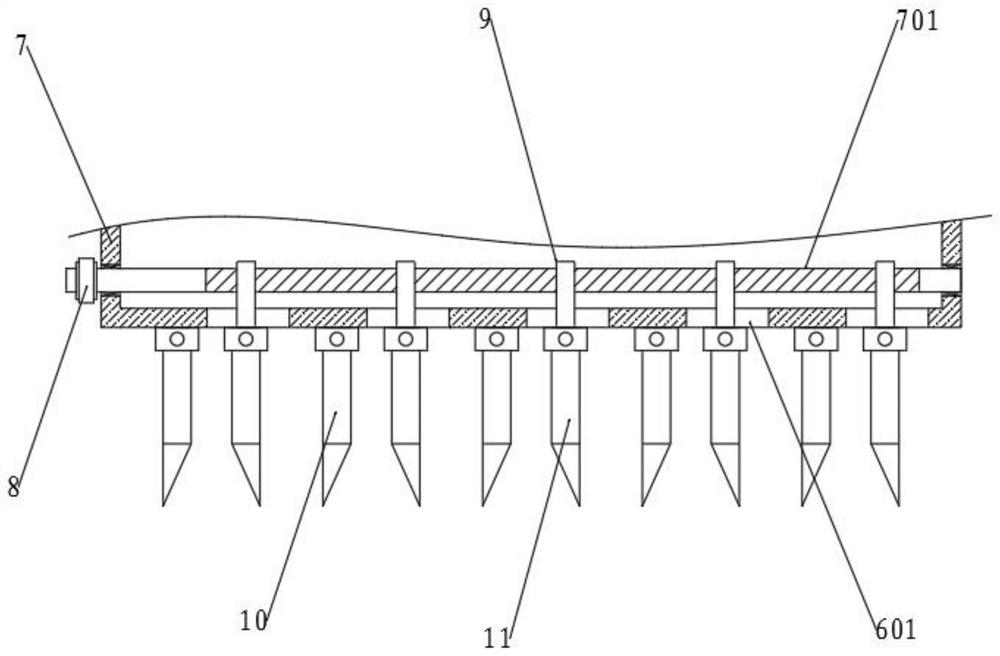

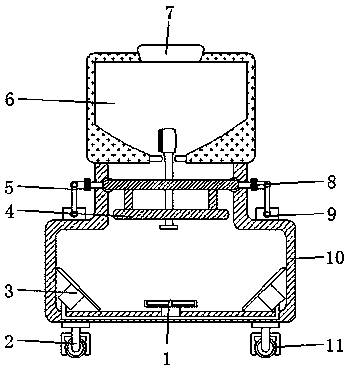

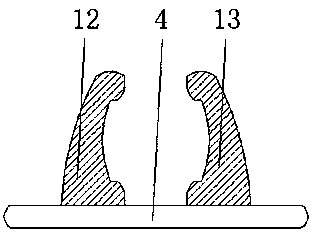

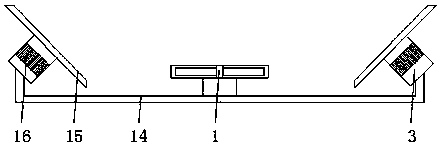

Multifunctional intelligent leaf vegetable harvesting and bundling all-in-one machine

ActiveCN114631424AFor subsequent storageEasy packing jobReaper-bindersAgricultural scienceAgricultural engineering

The invention relates to the technical field of leaf vegetable harvesting and bundling, in particular to a multifunctional intelligent leaf vegetable harvesting and bundling all-in-one machine which comprises a harvester base, a processing box is arranged on the right side of the upper end of the harvester base, and a vegetable conveying mechanism and a harvesting assembly are installed on the harvester base and located on the right side of the processing box. The vegetable conveying mechanism is matched with the ordered arrangement assembly; a discharging barrel and a bundling box are arranged in the treatment box, through openings are formed in the upper end and the lower end of the discharging barrel, the bottom end of the discharging barrel is fixedly connected with the bundling box through supporting legs which are in bilateral symmetry, and a quantitative discharging assembly is arranged in the discharging barrel; a feeding cavity is formed in the position, corresponding to a through opening in the bottom end of the treatment box, of the middle of the bundling box, a bundling mechanism is installed in the feeding cavity, and a sealing strip heating and cutting mechanism is arranged on the bundling mechanism in a matched mode. Through mutual cooperation of all the components, harvesting and bundling integrated work of leaf vegetables can be completed, and the working efficiency of the harvesting and bundling integrated machine is improved.

Owner:LANZHOU CITY UNIV

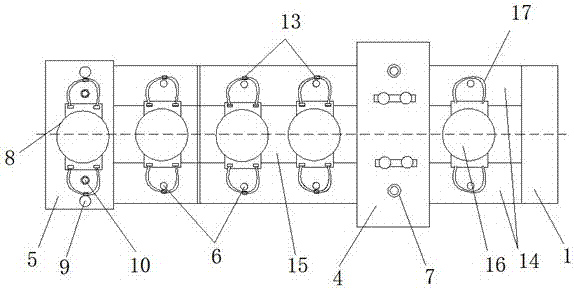

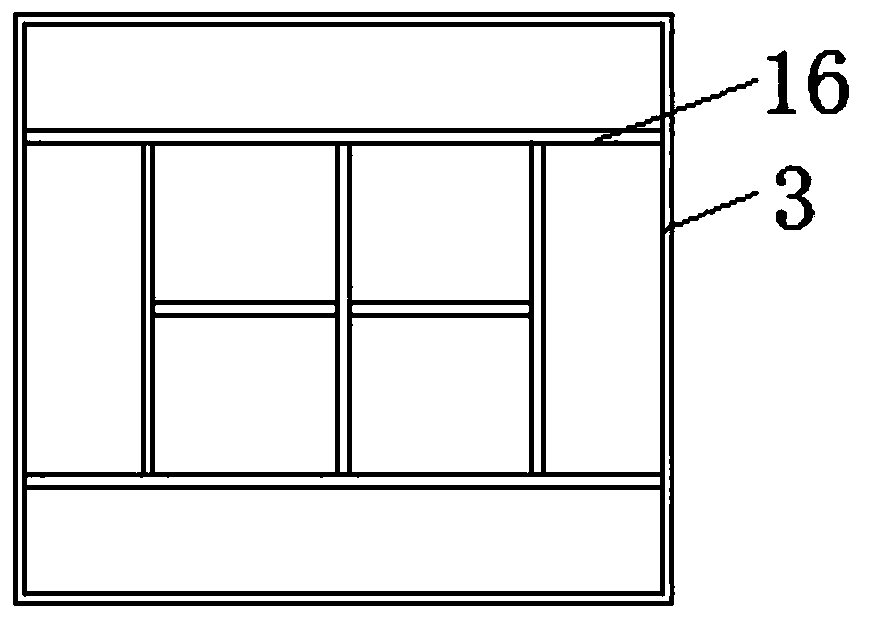

Drying-pressing type arraying device for toothbrush packaging machinery

InactiveCN109665147AControl the movement of the whole columnEasy to guarantee workPackagingHydraulic pumpEngineering

The invention discloses a drying-pressing type arraying device for a toothbrush packaging machinery, and belongs to the technical field of arraying for toothbrush packaging. The drying-pressing type arraying device for the toothbrush packaging machinery comprises a fan, universal wheels, air outlet nozzles, a feeding baffle plate, a conveying shaft, a feeding and integrating box, a feeding nozzle,a synchronizing shaft, a hydraulic pump, an equipment tank, a brake pad, a first fixed block, a second fixed block, an air outlet hose pipe, an electric heating coil and an air disc, wherein the feeding and integrating box is welded to the top end of the equipment tank; the feeding baffle plate is arranged in the equipment tank and is slidably connected with the equipment tank through a sliding chute; the hydraulic pump is arranged at the upper end of the equipment tank; a hydraulic push rod of the hydraulic pump is connected with one end of the synchronizing shaft through a conveying shaft;the other end of the synchronizing shaft and the feeding baffle plate are welded through the sliding chute penetrating through the equipment tank; the fan is fixed into the equipment tank and communicate with the air outlet nozzles through the air outlet hose pipe; and the air disc is fixed onto the air outlet nozzles. The drying-pressing type arraying device for the toothbrush packaging machineryprovided by the invention can be used for quickly arraying and blowing air for disinfecting.

Owner:BEIJIAJIE ORAL CARE PROD SUQIAN CO LTD

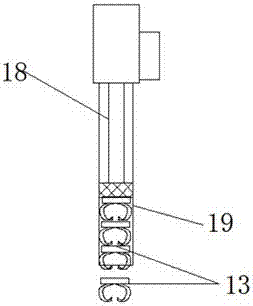

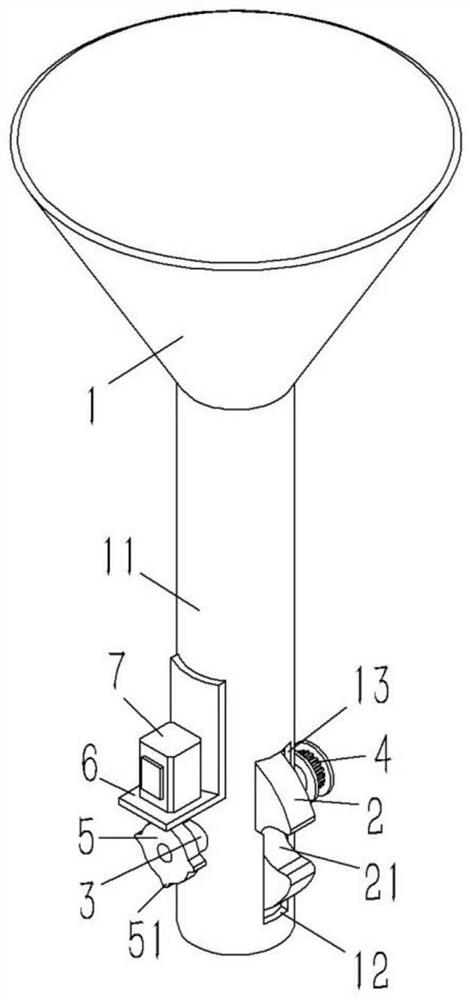

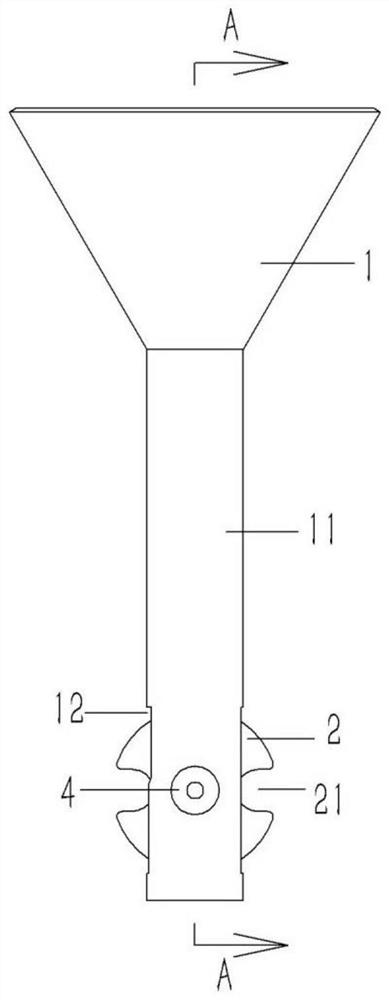

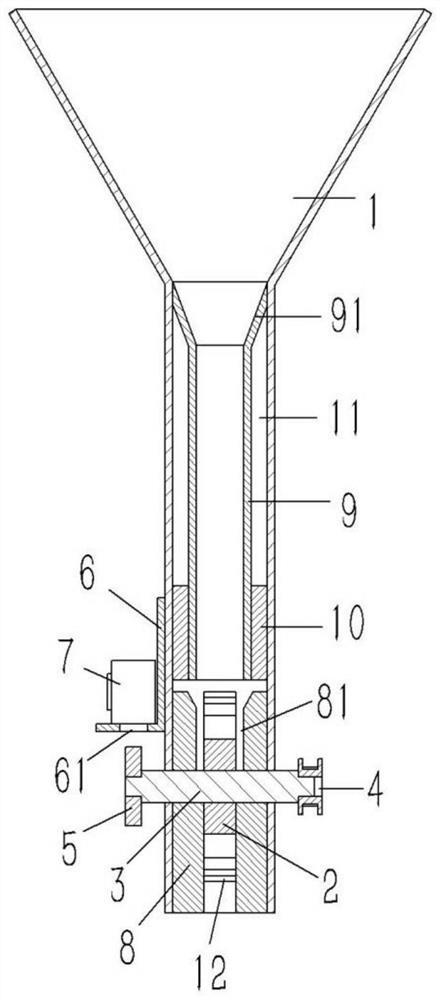

One-by-one delivering device for bearing balls for packaging

The invention discloses a one-by-one delivering device for bearing balls for packaging. The device comprises a conical hopper, a vertical outer delivering pipe is formed at the lower end of the hopper, rectangular inserting grooves are formed in two opposite side walls of the lower end of the outer delivering pipe, and a delivering groove is formed in the side wall of the upper end of the inserting groove in one side of the outer delivering pipe; material distributing wheels are inserted into the inserting grooves of the outer delivering pipe, and a plurality of U-shaped material distributinggrooves are formed in the outer rings of the material distributing wheels; and a driving shaft is inserted and fixed in the center of each material distributing wheel, one end of the driving shaft extends out of the outer delivering pipe to be sleeved and fixed with a belt wheel, the other end of the driving shaft extends out of the outer delivering pipe to be sleeved and fixed with a counting wheel, a plurality of counting flanges are formed on the counting wheel, a counting sensor opposite to the counting flanges is arranged above the counting wheel and fixed to an L-shaped support plate, and the support plate is fixed on the outer wall of the outer delivering pipe.

Owner:张红英

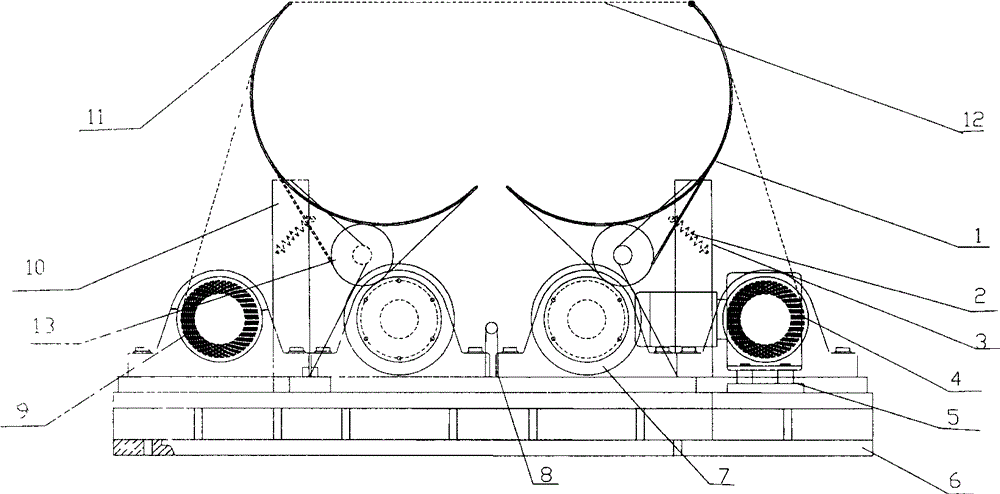

Gravity-type automatic film laminating machine for roll

ActiveCN102407950BLabor-saving packagingEasy packing jobWrapping material feeding apparatusEngineeringDrive motor

The utility model relates to automatic film laminating equipment for a roll, in particular to a gravity-type automatic film laminating machine for the roll, which comprises an electric appliance operating platform and a base. The gravity-type automatic film laminating machine is characterized in that the machine additionally comprises a film roll with a plastic film, a waste roll, a pair of supporting rollers, a proximity switch, a roll fastening mechanism and a heating and cutting device; the film roll and the waste roll are respectively arranged on the two sides of the base and are connected through the plastic film and the waste roll is provided with a driving motor; the supporting rollers are arranged in parallel with the film roll and the waste roll and are arranged between the film roll and the waste roll; the proximity switch is arranged between the two supporting rollers; the roll fastening mechanism comprises two semicircular fastening plates which can be opened and closed to form a circle, the fastening plates are supported through supporting frames which are fixed on the base and are arranged on the two sides of the supporting rollers, and the film crosses over the tops of the two fastening plates; the upper ends of the two fastening plates are edges and are provided with heating resistance wires; and the width of the plastic film is larger than the width of the roll to be wrapped. By using the gravity-type automatic film laminating machine, the roll can be packaged in the shortest time.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

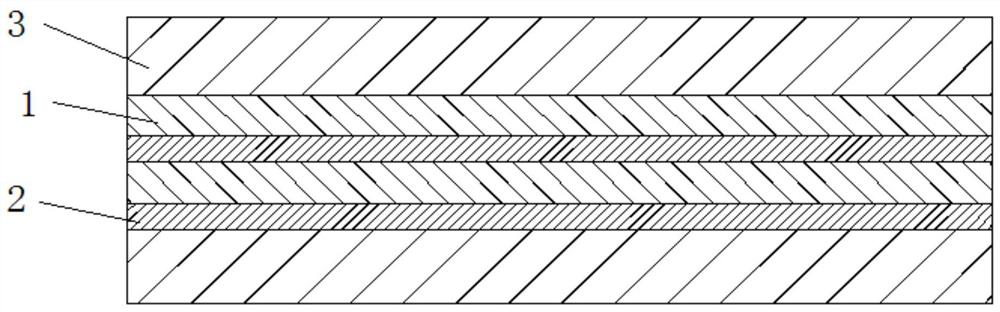

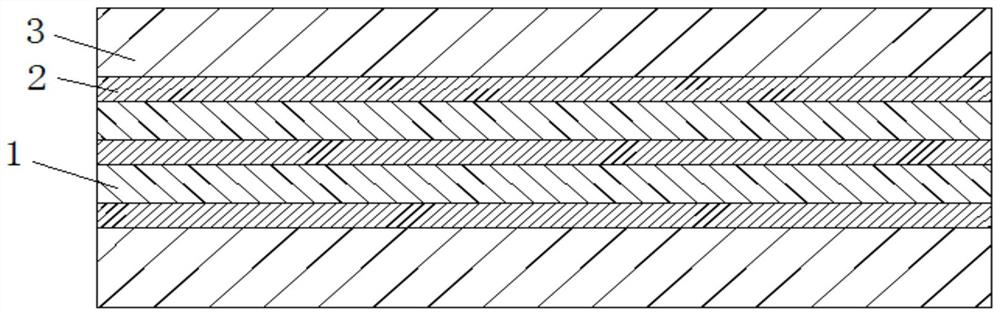

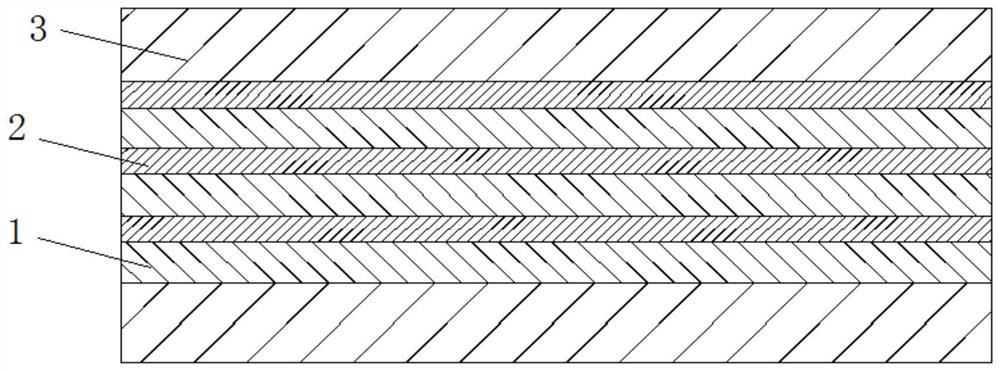

Energy-saving film for fabricated component

InactiveCN112677594AIncrease elasticityGood extensibilitySynthetic resin layered productsPolymer scienceInsulation layer

The invention discloses an energy-saving film for a fabricated component, the energy-saving film comprises a plurality of heat insulation layers, a plurality of plastic layers and a plurality of wear-resistant layers, the heat insulation layers and the plastic layers are alternately stacked to form a base film, and the wear-resistant layers are arranged on the outer surface of the base film; the heat insulation layer is prepared from the following raw materials in percentage by weight: 60-70% of resin, 20-30% of an ultraviolet light absorber and 5-10% of a dispersing agent; the plastic layer is prepared from the following raw materials in percentage by weight: 70-80% of polyolefin, 10-20% of sodium methyl silicate, 5-8% of glycerol and 3-5% of a stabilizer; and the wear-resistant layer is prepared from the following raw materials in percentage by weight: 30-40% of PET, 20-30% of polyvinyl alcohol, 5-10% of titanium dioxide, 5-10% of ethylenediamine, 1-10% of nano silicon carbide, 5-8% of graphene oxide and 3-5% of a lubricant.

Owner:徐翔宇

Working method of automatic adhesive coating device

InactiveCN112892992AStable structureEasy packing jobLiquid surface applicatorsCoatingsGear wheelElectric machinery

The invention discloses a working method of an automatic adhesive coating device. The working method comprises the following specific step I of continuously putting punches into a telescopic pipe on the leftmost side of the front row; the step II of driving an incomplete gear by a stepping motor to rotate anticlockwise, driving transmission gears and a conveying chain to rotate by the incomplete gear through an intermittent driving assembly, so that the punches are rotated intermittently; and the step III of driving a cog belt to rotate by the incomplete gear through a second locking gear and a large gear, and pressing the punches in the telescopic pipe to dip in an adhesive pool by the cog belt through a pressing assembly. The method has the advantages that the structure is stable and reliable, and the punches can be automatically rotated in sequence, pressed into the adhesive pool and dipped with hot melt adhesive; the punches are raised and reset, and in the pressing and rising process of the punches, two lifting strips are raised to erect the punches; after the two lifting strips are descent and reset, the punches are sequentially arranged on a concave part, meanwhile, follow-up packaging work is facilitated; and the working efficiency is improved.

Owner:宁波市鄞州承润科技有限公司

Quantitative packaging and sealing device for mashed garlic production

InactiveCN114313348AEasy to slideEasy to locate and protectLiquid materialProcess engineeringHermetic packaging

The invention relates to the technical field of sealed packaging, in particular to a quantitative packaging and sealing device for mashed garlic production, which comprises a packaging machine, a feeding mechanism is mounted on the packaging machine, a locking mechanism is mounted on the feeding mechanism, a closing mechanism is mounted on the feeding mechanism, a feeding mechanism is connected to the feeding mechanism, and a sealing mechanism is mounted on the sealing mechanism. A moving mechanism is connected to the packaging machine, and a driving mechanism is installed on the moving mechanism. Through cooperation of the locking mechanism and the feeding mechanism, feeding can be conveniently conducted on the packaging machine, physical output of manual lifting and feeding of mashed garlic at the lower position is reduced, the feeding mechanism is protected during one-time lifting, and danger caused by slipping is prevented; mashed garlic can be extruded and conveyed into the packaging machine for packaging work through cooperation of the closing mechanism and the feeding mechanism, the packaging machine can be conveniently moved and braked under cooperation of the driving mechanism and the moving mechanism, and it is guaranteed that the packaging machine can stably work in different areas.

Owner:邳州祥懋生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com