Energy-saving film for fabricated component

An energy-saving film and assembled technology, which is applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problem of poor wear resistance and elastic properties of energy-saving films, affecting the packaging efficiency of components, and prone to damage, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

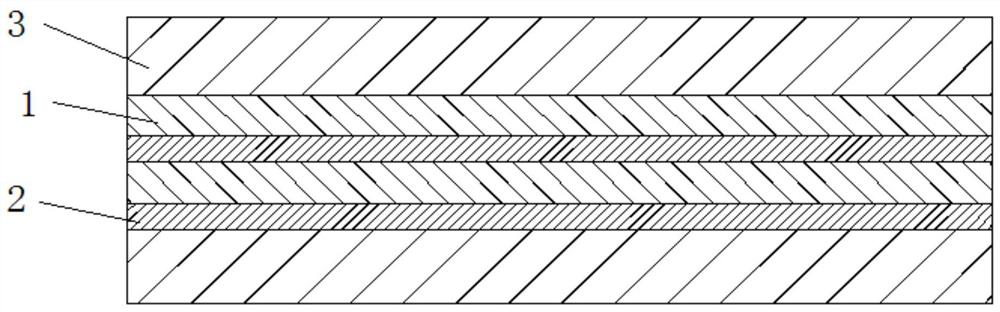

[0022] Embodiment 1, as figure 1 As shown, the energy-saving film used for assembled components in this embodiment includes a heat-insulating layer 1, a plastic layer 2, and a wear-resistant layer 3. The heat-insulating layer 1 and the plastic layer 2 have two layers. The thermal layer 1 and the plastic layer 2 are alternately stacked to form a base film (that is, a layer of heat-insulating film, a layer of plastic film, a layer of heat-insulating film, and a layer of plastic film are alternately stacked to form a base film), and the wear-resistant layer 3 set on the outer surface of the base film;

[0023] Between the heat insulation layer 1 and the plastic layer 2, between the anti-friction layer 3 and the base film, the adhesive is bonded; the adhesive is prepared from the following raw materials in weight percentage: polybutadiene epoxy resin 40% , Bisphenol A epoxy resin 20%, phenoxy resin 20%, ethylenediamine phosphate 20%.

[0024] The heat insulation layer 1 is prepa...

Embodiment 2

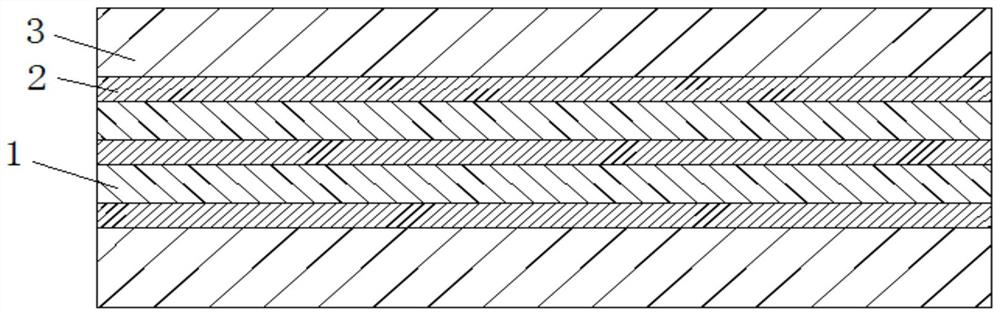

[0027] Embodiment 2, as figure 2 As shown, the energy-saving film used for assembled components in this embodiment includes a heat insulating layer 1, a plastic layer 2, and a wear-resistant layer 3. The heat insulating layer 1 has two layers, and the plastic layer 2 has three layers. The heat insulation layer 1 and the plastic layer 2 are alternately stacked to form a base film, and the wear-resistant layer 3 is arranged on the outer surface of the base film;

[0028] Between the heat insulation layer 1 and the plastic layer 2, between the anti-friction layer 3 and the base film are bonded by an adhesive; the adhesive is prepared from the following raw materials in weight percentage: polybutadiene epoxy resin 30% , Bisphenol A epoxy resin 30%, phenoxy resin 30%, xylene 10%.

[0029] The heat insulation layer 1 is prepared from the following raw materials in weight percentage: 65% resin, 25% 2,4-dihydroxybenzophenone, and 10% sodium tripolyphosphate; the thickness of the hea...

Embodiment 3

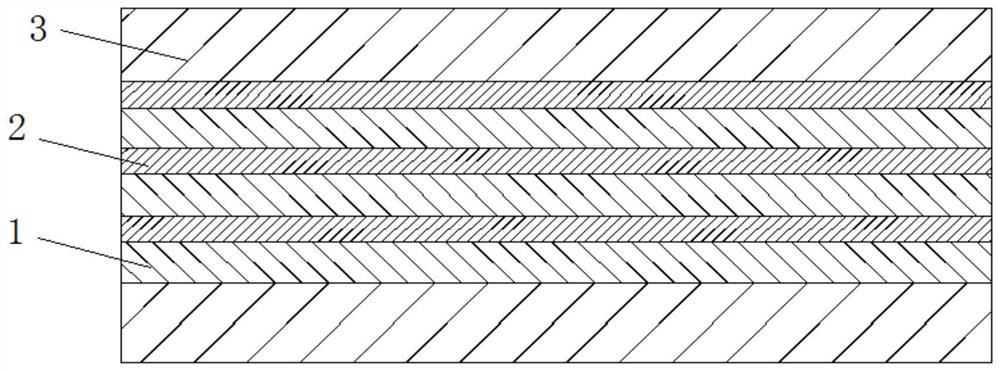

[0032] Embodiment 3, as image 3 As shown, the energy-saving film used for assembled components in this embodiment includes a heat-insulating layer 1, a plastic layer 2, and a wear-resistant layer 3. The heat-insulating layer 1 and the plastic layer 2 have three layers, and the heat-insulating layer Layer 1 and plastic layer 2 are alternately stacked to form a base film, and the wear-resistant layer 3 is arranged on the outer surface of the base film;

[0033] Between the heat insulation layer 1 and the plastic layer 2, between the anti-friction layer 3 and the base film, the adhesive is bonded; the adhesive is prepared from the following raw materials in weight percentage: polybutadiene epoxy resin 40% , Bisphenol A epoxy resin 30%, phenoxy resin 20%, ferrous sulfate 10%.

[0034] The heat-insulating layer 1 is prepared from the following raw materials in weight percentage: 70% of resin, 20% of 2-hydroxy-4-n-octyloxybenzophenone, and 10% of sodium persulfate; the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com