Multifunctional intelligent leaf vegetable harvesting and bundling all-in-one machine

A multi-functional and integrated machine technology, which is applied in the direction of harvesters, balers, agricultural machinery and implements, etc., can solve the problem of inconvenient and orderly transportation, quantitative bundling and packaging, lack of leafy vegetable structure, and inconvenient leafy vegetable packaging. Binding and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

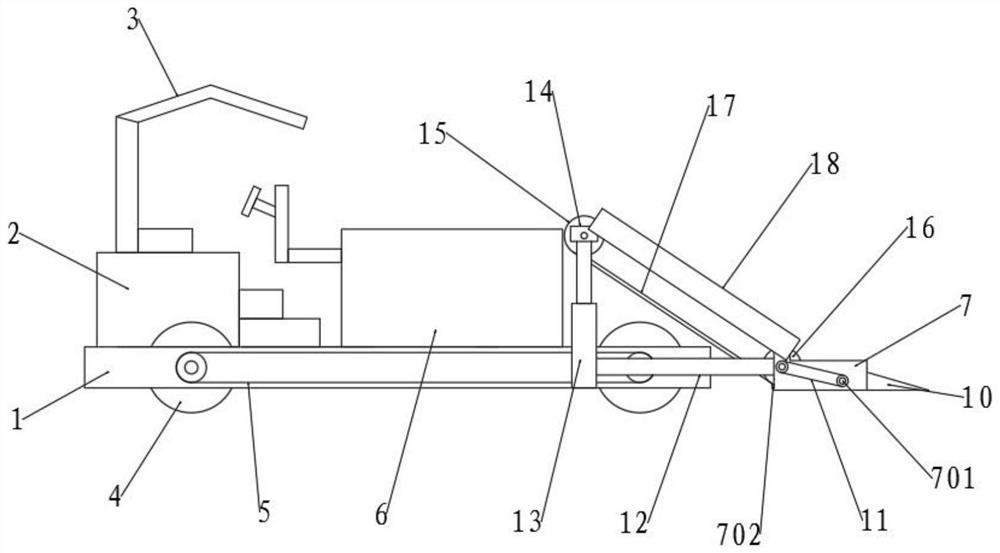

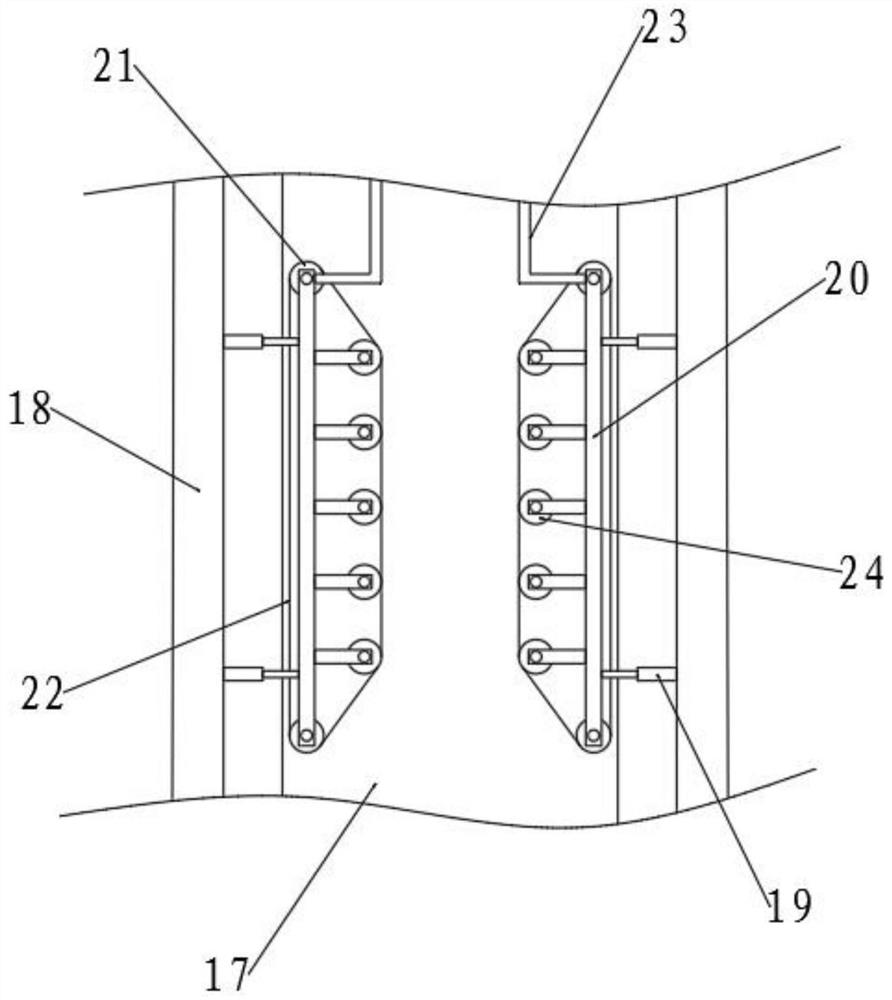

[0029] A multifunctional intelligent leaf vegetable harvesting and bundling integrated machine, comprising a harvester base 1, four wheels 4 are installed at the bottom end of the harvester base 1, and the two wheels 4 on the front side are driven by a sprocket set-5 Connected and controlled by the driving device to move the wheels 4, a driver's seat 2 is provided on the left side of the upper end of the harvester base 1, and a processing box 6 is provided on the right side of the upper end. The harvester base 1 is located on the right side of the processing box 6. assembly, and the vegetable conveying mechanism cooperates with the orderly sorting assembly;

[0030] A steering wheel is arranged in front of the driver's seat 2, and an awning 3 is fixedly installed on the left side of the steering wheel 6 at the upper end of the driver's seat 2; Through port 251, the bottom end of the lower material barrel 25 is fixedly connected with the bundling box 29 through the left and rig...

Embodiment 2

[0041] The difference from Example 1 is that:

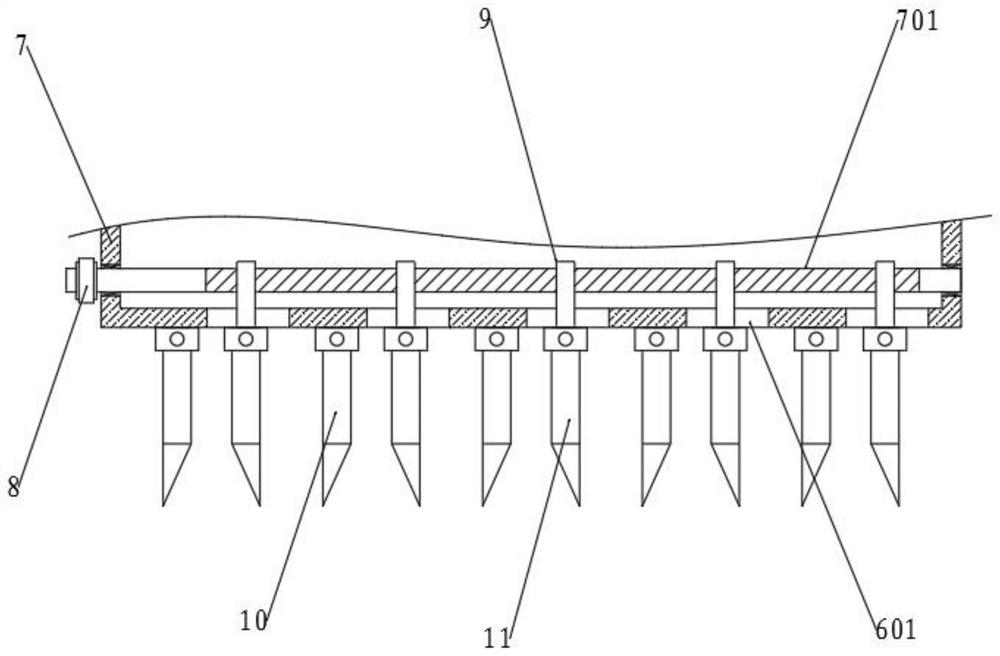

[0042] The left end of the harvesting frame 7 is provided with a moldboard 702 that can fit with the conveyor belt 17 , so as to facilitate scraping and cleaning of the soil that may be attached to the conveyor belt 17 .

[0043] Working method: The steps of Example 2 are the same as the steps of harvesting vegetables in Example 1. The only difference is that the soil attached to the surface of the conveyor belt 17 can be scraped off by the moldboard 702 to avoid excessive soil. Attached to the surface of the conveyor belt 17, it affects the conveying work of the conveyor belt 17, making it more convenient and safe to use.

[0044] The motors, hydraulic rods, and fresh-keeping films used in this patent are all commercially available, and their structures and control methods are in the prior art, and will not be repeated in the description.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com