Preparation process of flame-retardant antibacterial easily-degradable plastic master batch

A technology of plastic master batch and preparation process, applied in the field of plastic master batch processing, can solve the problems of uneven mixing, inability to quantitatively discharge, and difficult to package, and achieve the advantages of convenient packaging, improving the quality of plastic products, and reducing labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

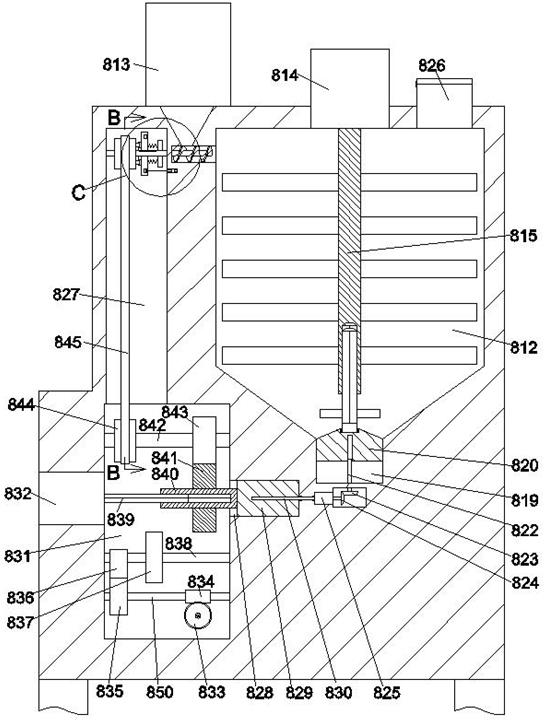

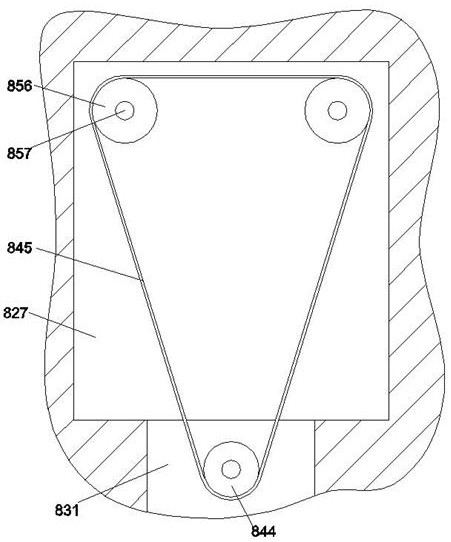

[0036] When it is necessary to add materials to the left and right side feeding boxes 813 at the same time, the second motor 832 drives the second outer key shaft 839 and the first gear 841 on the second inner key rotating sleeve 840 to rotate, and then drives the second gear 841 with the first gear 841. The second gear 843 and the second pulley 844 rotate. At this time, the electromagnets 868 on the left and right sides are kept in a power-off state, and then the transmission belt 845 on the second pulley 844 drives the first pulley 856 to rotate. 858 cooperates with the draw-in groove ring block 871 to lock the connection state, and then the first rotating shaft 857 is driven by the first disc 862 to rotate. The material enters the delivery channel 860 through the funnel-shaped groove 859 and is delivered to the mixing chamber 812;

Embodiment 2

[0038] When it is necessary to add material to the feeding box 813 on one side, by controlling the electromagnet 868 on the corresponding side to power on, the magnetic slider 866 and the electromagnet 868 will generate suction, and then the magnetic slider 866 will drive the first circle through the connecting rod 867. The disc 862 overcomes the first spring 870 and moves toward the front side, and then the first disc 862 drives the locking groove ring block 871 away from the locking tooth 858. At this time, the second outer key shaft 839 and the second inner key shaft are driven by the second motor 832 The first gear 841 on the rotating sleeve 840 rotates, and then drives the second gear 843 and the second belt pulley 844 to rotate with the first gear 841. The first pulley 856 idles, and drives the first pulley 856 on the other side to rotate, and the locking teeth 858 on the first pulley 856 drive the corresponding snap-in groove ring block 871 and the first disc 862 to rota...

Embodiment 3

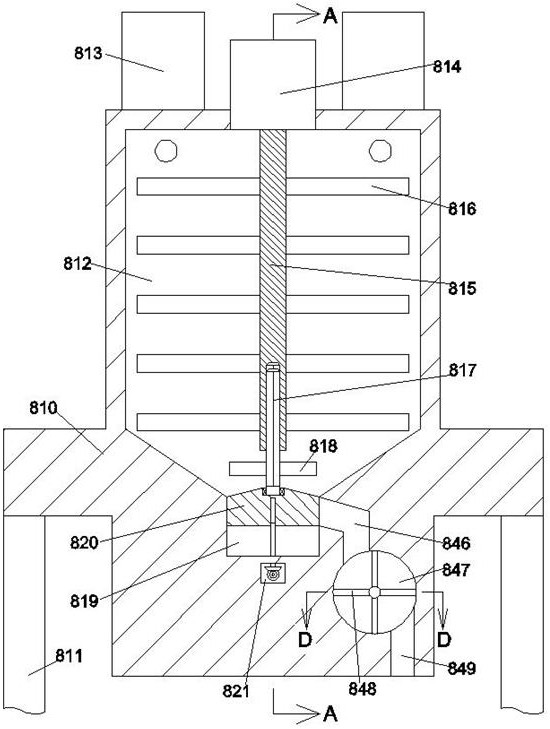

[0040] First, load the raw material through the raw material injection port 826, then control the feeding work through the linkage feeding mechanism, and then drive the first inner key swivel 815 to rotate through the first motor 814, and the first outer key is driven by the first inner key swivel 815 The shaft 817 rotates. At this moment, the first blade 816 is driven by the first inner key rotating sleeve 815 to mix the mixing chamber 812 of the upper section, and at the same time, the mixing chamber 812 of the lower section is mixed by the second blade 818. Stirring work, after the mixing is completed, the third motor 825 drives the second bevel gear 824 and the second screw rod 830 to rotate. At this time, the second bevel gear 824 drives the first bevel gear 823 and the first screw rod 822 to rotate, so that the second A screw 822 drives the lifting sealing slider 820 to move to the bottom position in the lifting chute 819. At this time, the first channel 846 is in a state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com