Gravity-type automatic film laminating machine for roll

A gravity type, laminating machine technology, applied in the directions of external support, transportation packaging, packaging, etc., can solve the problems of low work efficiency, unsafe, troublesome operation, etc., and achieve the effect of labor-saving packaging work, low maintenance cost and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

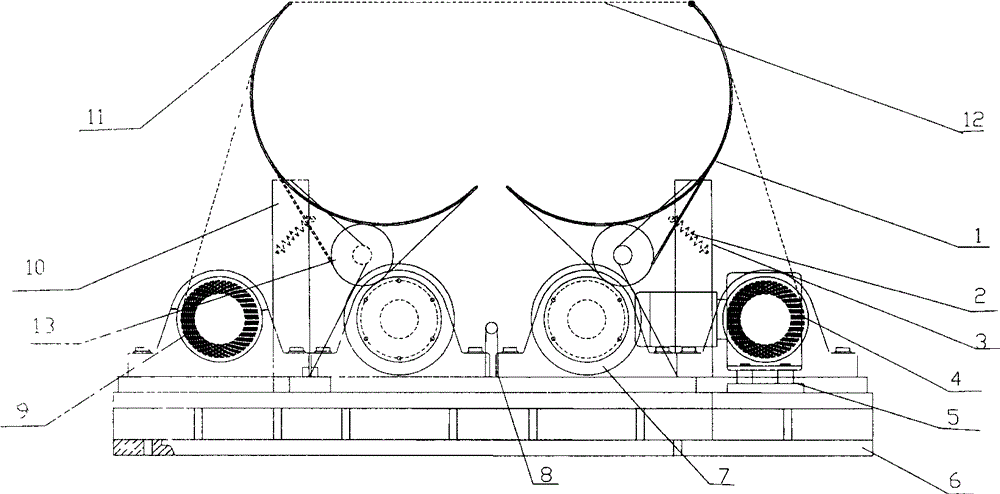

[0015] like figure 1 Shown, a kind of roller gravity type automatic laminating machine, it comprises electric operating table and base 6, and it comprises:

[0016] A film roll 9 and a waste roll 5 equipped with a plastic film 13 are respectively arranged on both sides of the base, the film roll 9 and the waste roll 4 are connected by the plastic film 13, and the waste roll 4 is provided with a driving motor 5; the width of the plastic film 13 is greater than the length of the roll to be coated;

[0017] A pair of supporting rollers 7, they are arranged in parallel with film roll 9, waste material roll 4 and are positioned between film roll 9 and waste material roll 4;

[0018] Proximity switch 8, it is arranged between two supporting rollers 7;

[0019] A buckle roller mechanism, which includes two semicircular buckle plates 1 that can be opened and closed into a circle, and the buckle plate 1 is supported by support frames fixed on the base and positioned at both sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com