Self-adhesive strong high temperature resistant nylon composite film for waterproof coiled material and processing method thereof

A self-adhesive and composite film technology for roll materials, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve delamination, poor asphalt adhesion performance, and decrease in bonding strength between film and asphalt surface and other problems, to achieve the effect of high mechanical properties, high bonding strength and low peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

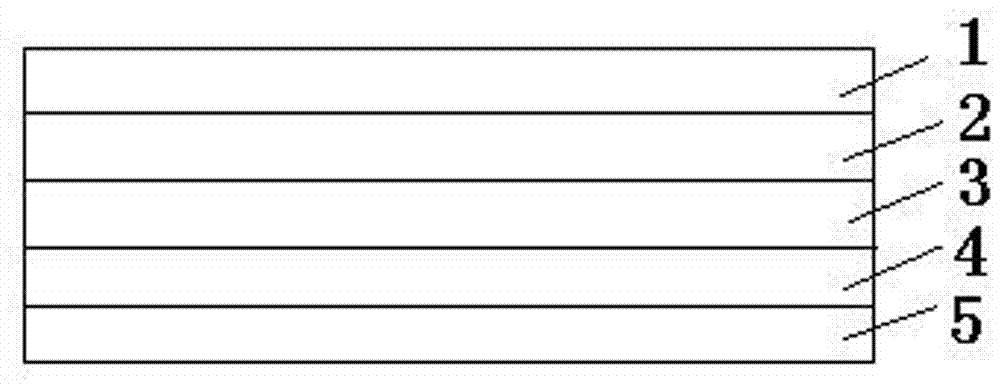

[0012] A self-adhesive strong high-temperature-resistant nylon composite film for waterproof coils, characterized in that the composite film includes a five-layer co-extrusion layer structure, and the five-layer co-extrusion layer structure is sequentially PIB self-adhesive layer 1, the first adhesive layer Agent layer 2, nylon reinforcement layer 3, second adhesive layer 4 and printing layer 5. According to a preferred embodiment of the present invention, the thickness ratio of the five-layer structure is: PIB self-adhesive layer: first adhesive layer: nylon reinforcing layer: second adhesive layer: printing layer=3:1:2: 1:3. Among them, the first and fifth layers are functional layers, the material price is relatively low, and the proportion is appropriately increased. The middle layer is a structural layer to ensure the mechanical properties and high temperature resistance of the membrane. The second and fourth layers are made of more expensive materials. Adhesive resin, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com