Waste recovery device for cowhide boot production and processing and use method of waste recovery device

A technology for waste recycling and boots, applied in packaging, chemistry, grain processing, etc., can solve the problems of inability to sterilize and unload leather waste, troublesome recycling, and inability to crush and handle leather waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

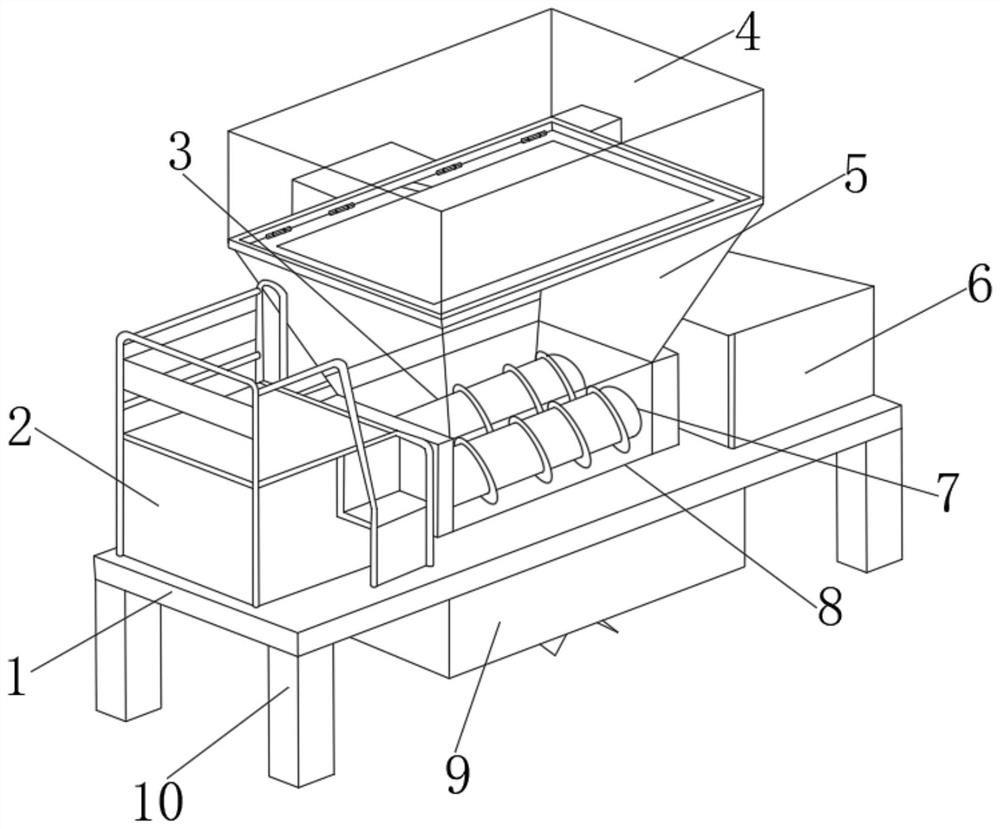

[0033] like Figure 1-7 As shown, a waste recycling device for the production and processing of cowhide boots includes a device base 1, a platform 2, a crushing box 8 and a driving box 6 are installed at the upper end of the device base 1, and support feet 10 are installed at the four corners of the device base 1, Inside the crushing box 8 is installed the driving wheel crushing roller 3 and the driven wheel driving roller 7, the upper end of the crushing box 8 is installed with a funnel 5, the upper end of the funnel 5 is installed with a feeding box 4, and the bottom of the device base 1 is installed with a blanking material Box 9.

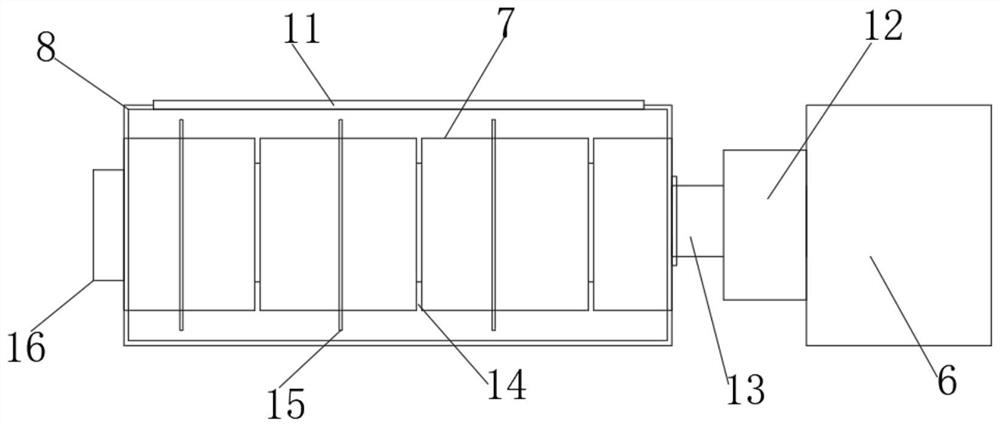

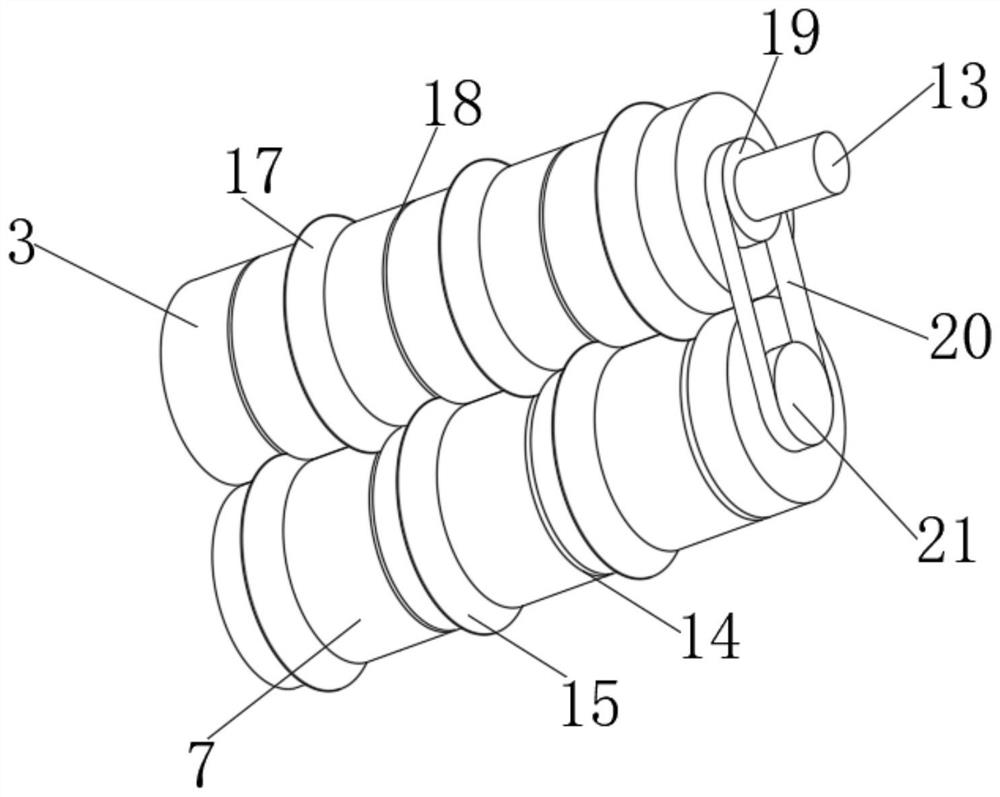

[0034] Further, an axle seat 16 is installed on the outside of the crushing box 8, and the axle seat 16 is connected with the driving wheel crushing roller 3 and the driven wheel driving roller 7. One end of the driving box 6 is installed with a reduction box 12, and one end of the reduction box 12 is provided with a The driving shaft 13, the d...

Embodiment 2

[0038] On the basis of Example 1, as Figure 1-7 As shown, a waste recycling device for the production and processing of cowhide boots includes a device base 1, a platform 2, a crushing box 8 and a driving box 6 are installed at the upper end of the device base 1, and support feet 10 are installed at the four corners of the device base 1, Inside the crushing box 8 is installed the driving wheel crushing roller 3 and the driven wheel driving roller 7, the upper end of the crushing box 8 is installed with a funnel 5, the upper end of the funnel 5 is installed with a feeding box 4, and the bottom of the device base 1 is installed with a blanking material Box 9.

[0039] Further, a feeding slot 24 is opened on the top of the unloading box 9, a driving cylinder 26 and a pump body 25 are installed on both ends of the unloading box 9, a telescopic rod 27 is arranged in the middle of the driving cylinder 26, and one end of the telescopic rod 27 is provided. A push plate 28 is install...

Embodiment 3

[0042] On the basis of Embodiment 1 and Embodiment 2, as Figure 1-7 As shown, a waste recycling device for the production and processing of cowhide boots includes a device base 1, a platform 2, a crushing box 8 and a driving box 6 are installed at the upper end of the device base 1, and support feet 10 are installed at the four corners of the device base 1, Inside the crushing box 8 is installed the driving wheel crushing roller 3 and the driven wheel driving roller 7, the upper end of the crushing box 8 is installed with a funnel 5, the upper end of the funnel 5 is installed with a feeding box 4, and the bottom of the device base 1 is installed with a blanking material Box 9.

[0043] Further, a feeding opening and closing plate 43 is installed on the top of the funnel 5, a weighing plate 42 is fixedly connected to the surface of the feeding opening and closing plate 43, and a weighing box 39 is installed at the rear end of the feeding opening and closing plate 43. A rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com