A cutting machine for automatic processing of defective materials

A technology of automatic processing and slitting machine, applied in thin material processing, sorting, sending objects, etc., can solve the problems of time-consuming, laborious, and heavy workload of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

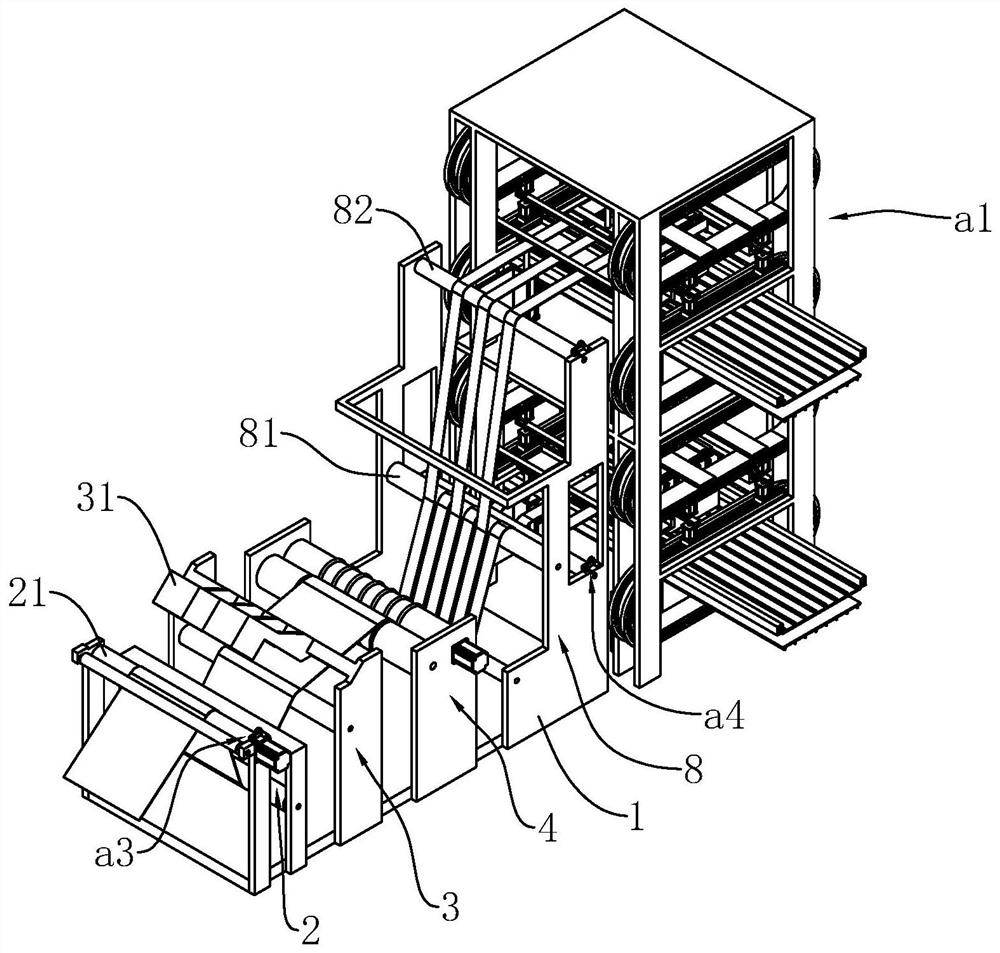

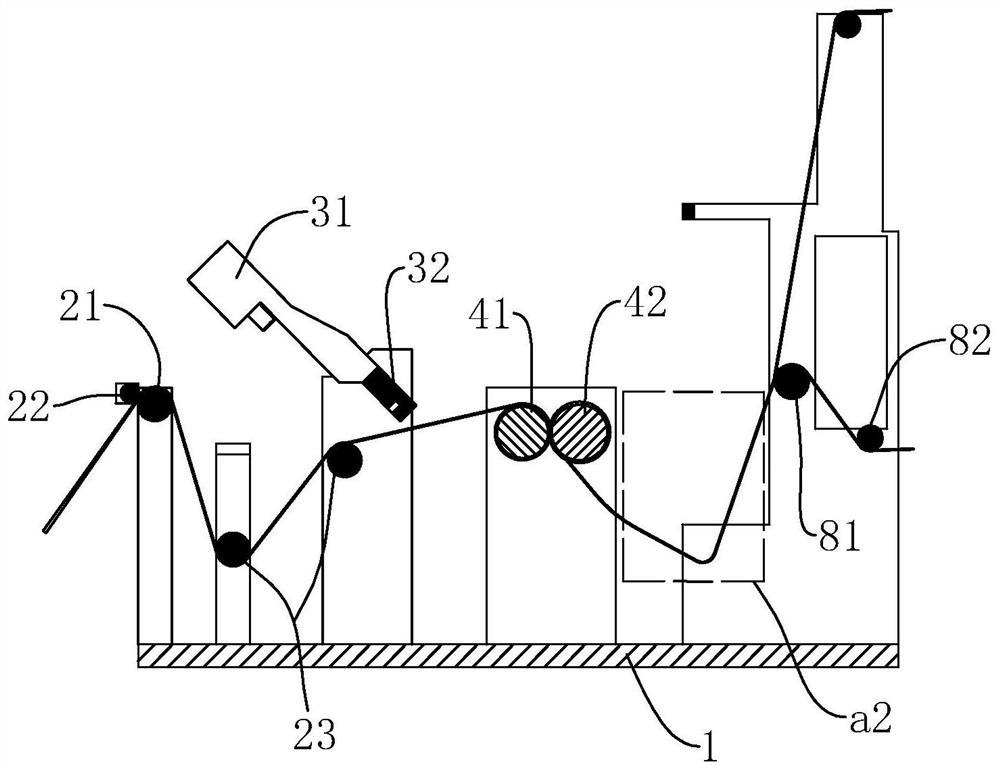

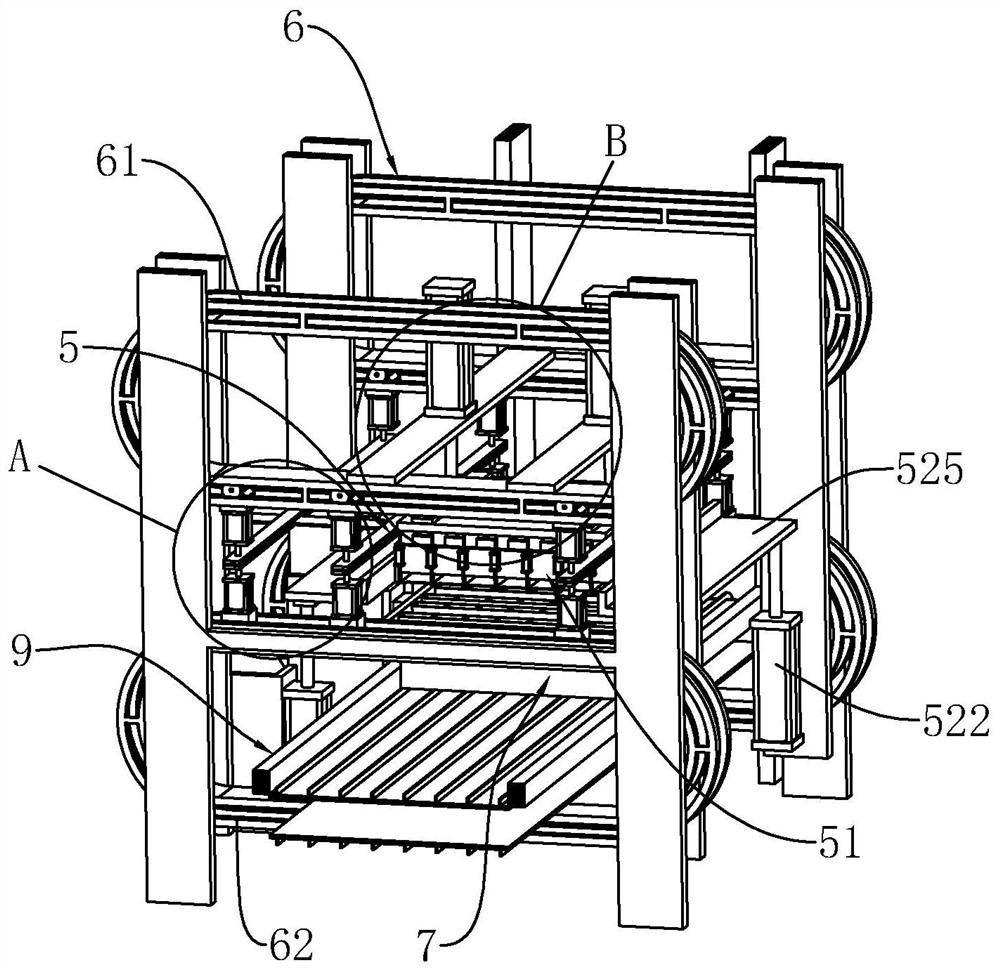

[0038] A slitting machine that automatically handles defective materials, such as figure 1 As shown, it includes a frame 1, on which an unwinding mechanism 2, a detection mechanism 3, a slitting mechanism 4, a reversing mechanism 8 and two cross-cutting sorting modules a1 arranged up and down are arranged in sequence along the material conveying direction . The material is pulled out from the unwinding mechanism 2, and the material first passes through the detection of the detection mechanism 3. The detection mechanism 3 can obtain information such as whether there is a defect in the printed pattern on the surface of the material, where the defect is located on the material, and the like. The material is then drawn into the slitter mechanism 4 for longitudinal cutting to form multiple strips of narrower width. Guided by the reversing mechanism 8, part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com