Working method of automatic adhesive coating device

A technology of encapsulation device and working method, which is applied to the device and coating of the surface coating liquid, which can solve the problems of burden, inconvenient placement, time-consuming and laborious, etc., and achieve the effect of improving work efficiency and stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

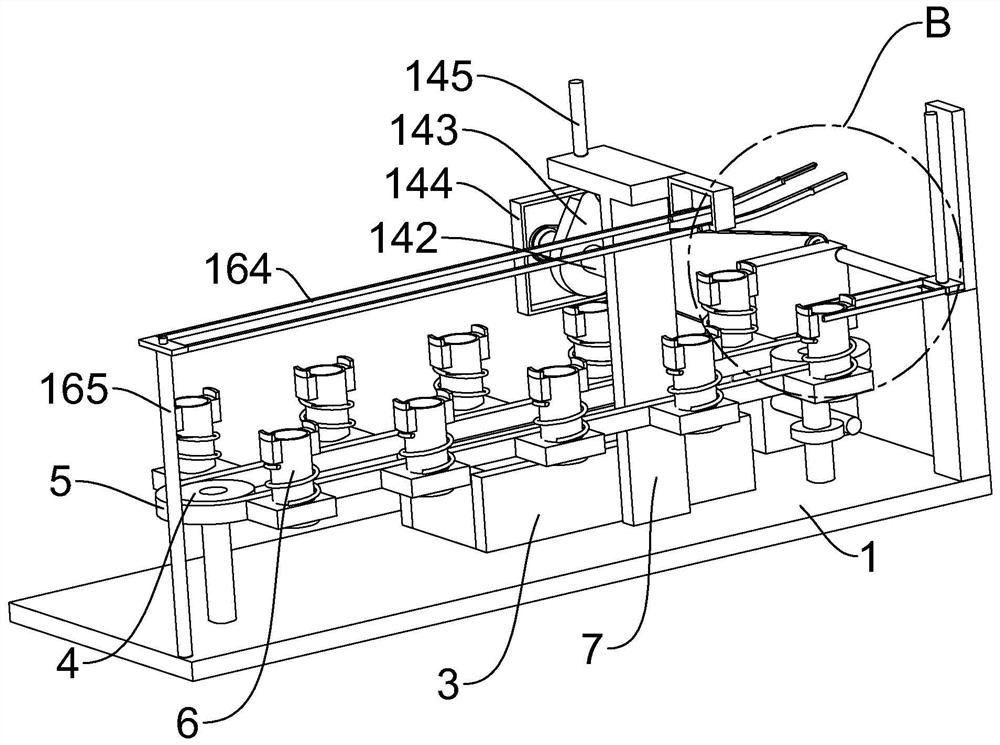

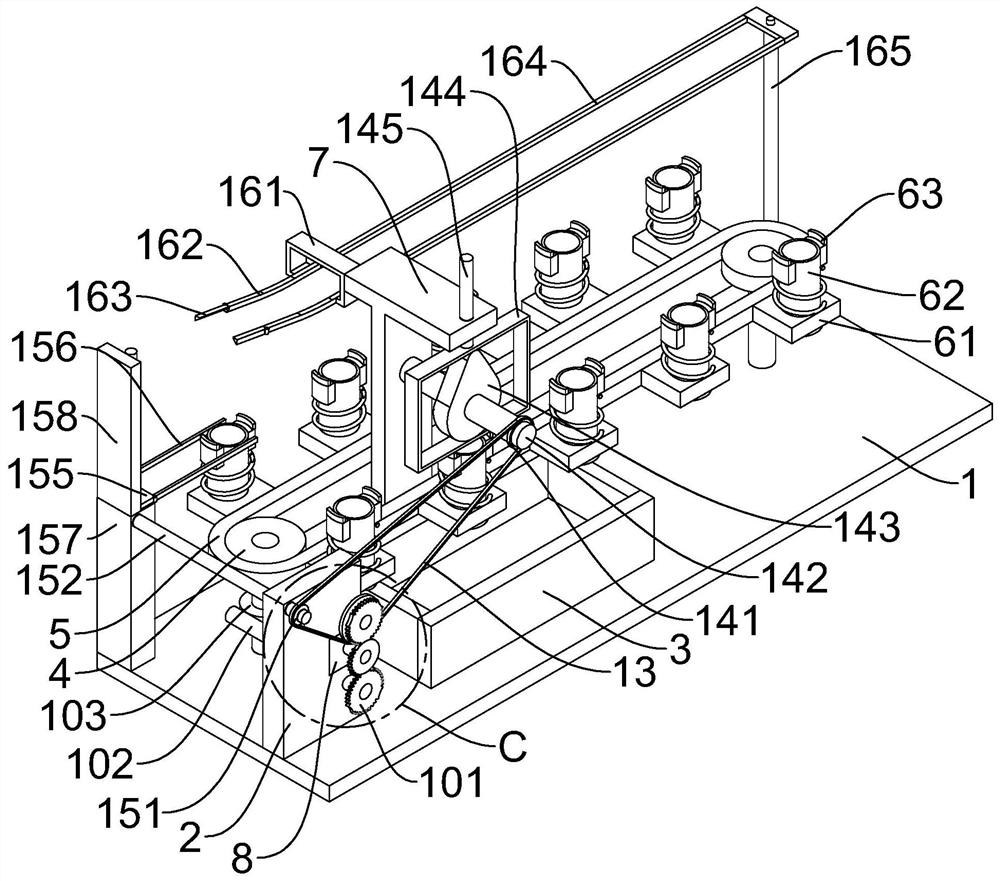

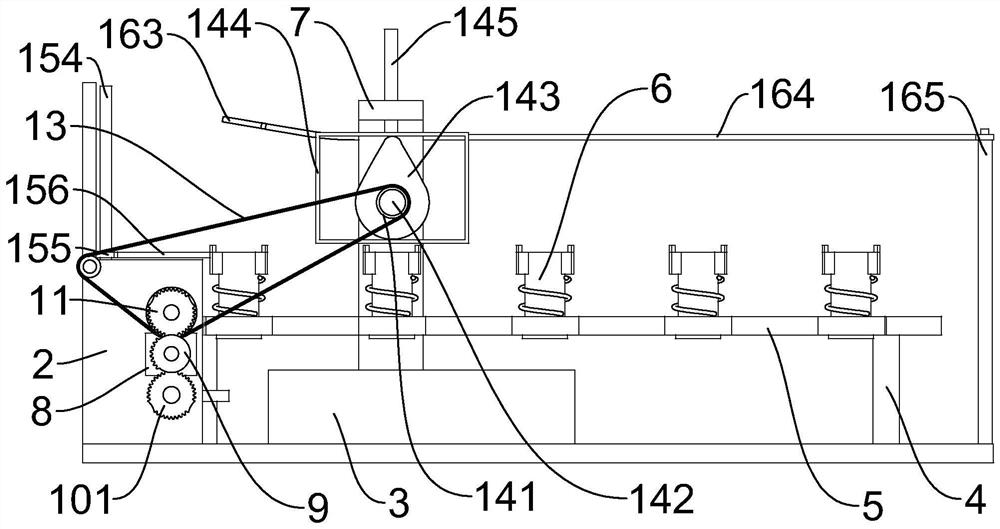

[0033] Such as Figure 1 to Figure 15 As shown, a working method of an automatic encapsulation device, the encapsulation device includes a base 1, the upper end of the base 1 is provided with a vertical block 2, the upper end of the base 1 is provided with a glue pool 3 on the right side of the vertical block 2, and the upper end of the base 1 The left and right sides of the body are symmetrically and rotationally provided with transmission teeth 4, and a transmission chain 5 is connected between the two transmission teeth 4, and telescopic parts 6 are evenly distributed on the transmission chain 5, and the upper end of the base 1 is provided with a T-shaped fixed block 7 , the vertical block 2 is provided with a stepping motor 8, the output shaft of the stepping motor 8 is keyed with an incomplete gear 9, and the vertical block 2 is provided with an intermittent gear that matches the incomplete gear 9 and the transmission tooth 4 on the left side. Drive assembly 10, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com