Sheet discharge tray and a multiple bin sorter equipped with the same

a multi-bin sorter and discharge tray technology, applied in the direction of pile receivers, thin material handling, transportation and packaging, etc., can solve the problems of reducing detection accuracy, and achieve the effect of reducing costs, facilitating packaging work, and compact structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

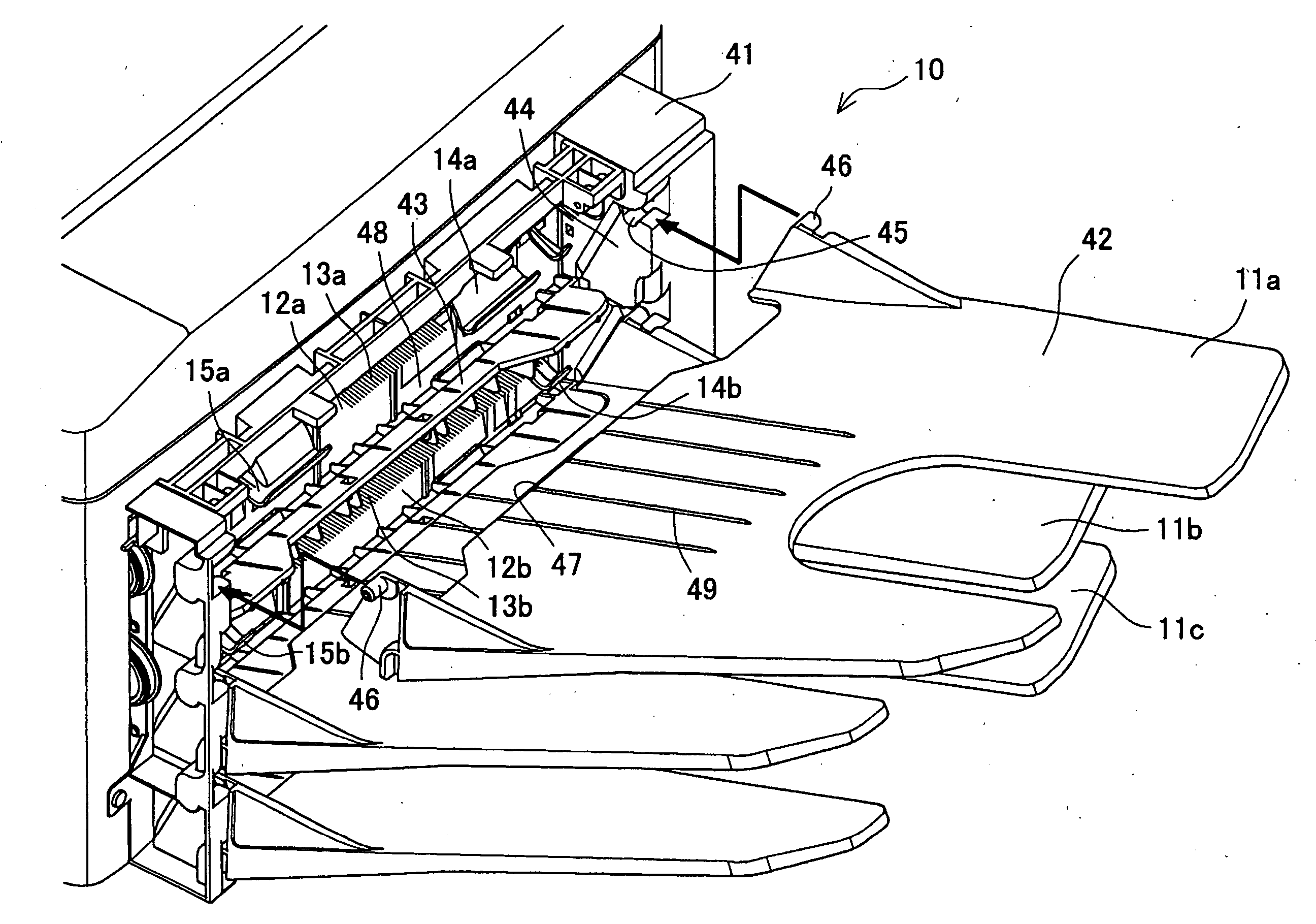

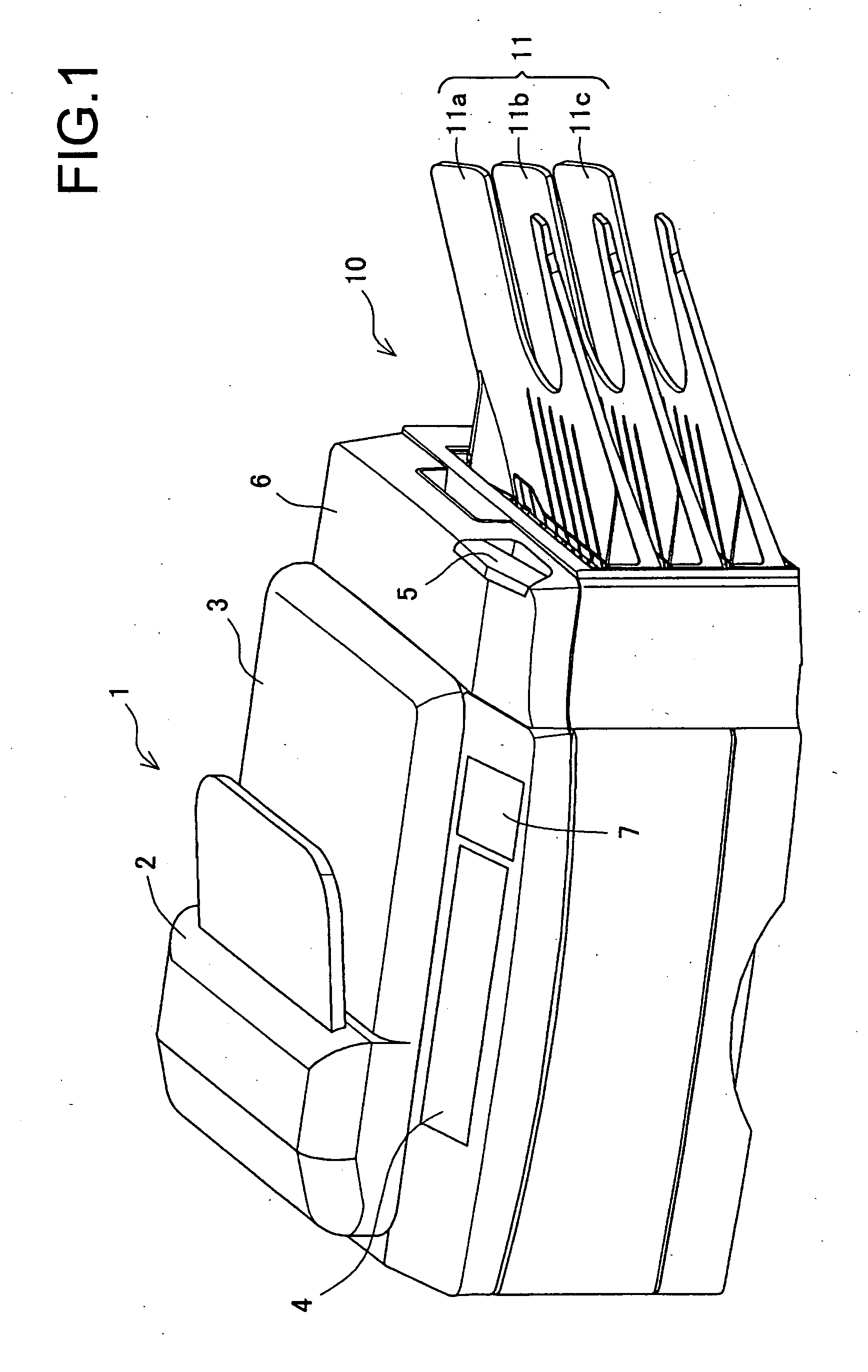

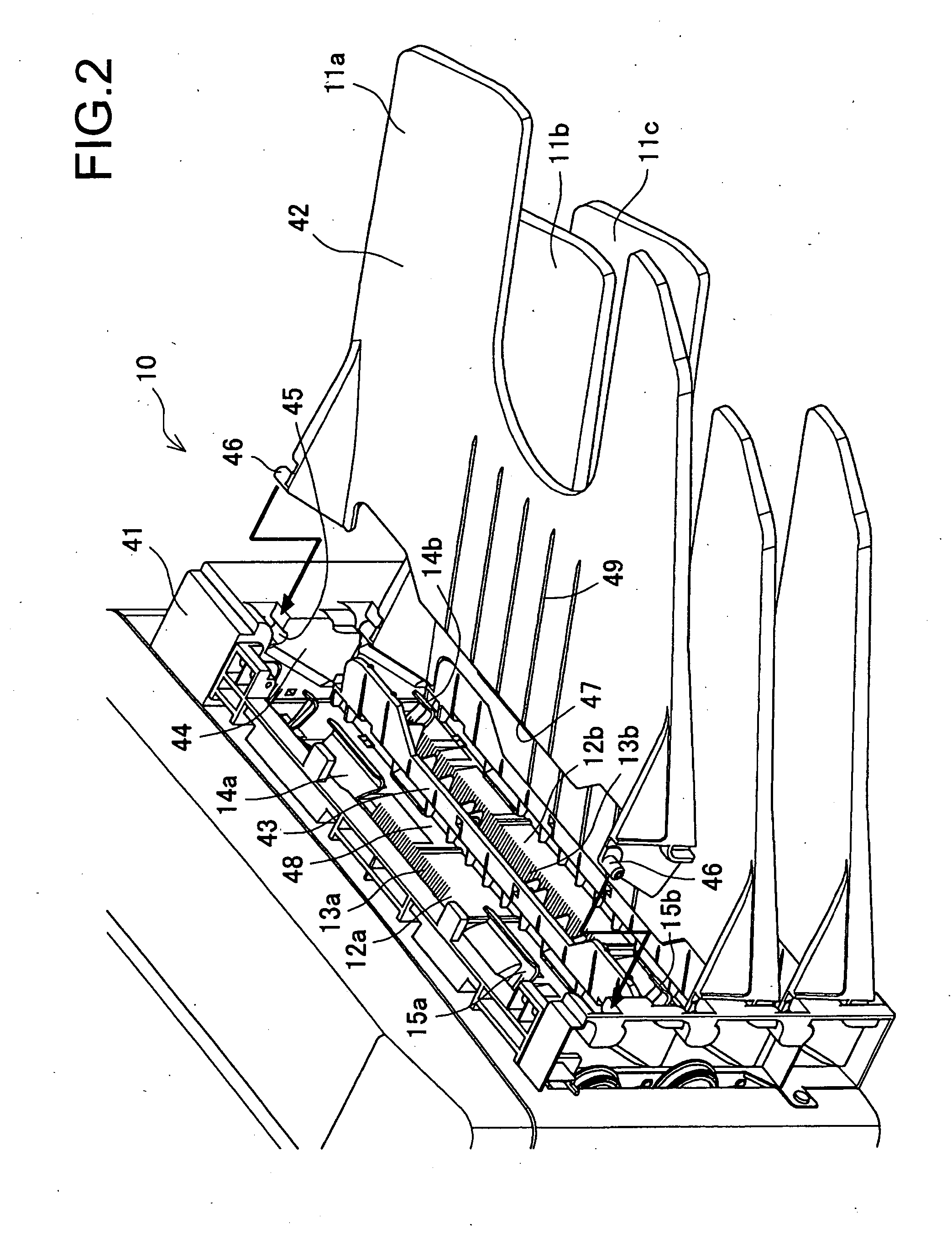

[0035] Preferred embodiments of the multi-bin sorter according to the present invention are described below with reference to the accompanying drawings.

[0036] As shown in FIG. 1, the multi-bin sorter 10 of the present invention is mounted to a side of an image forming apparatus having faxing, copying, scanning and / or printer functions as the main unit.

[0037] The image forming apparatus 1 has an automatic document feeder unit (commonly known as an ADF) 2 for automatically conveying originals, on the top portion of the apparatus. An image reading unit, not shown, for reading originals is arranged below the automatic document feeder 2. For that reason, the image reading unit can read originals using either of two methods. Specifically, this unit can read characters and images formed on an original while the original is conveyed by the automatic document feeder 2, or it can read characters and images formed on the original placed in a stationary position on a platen, not shown. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com