Interlayer paper divider of stacking machine

A technology of interlayer paper and stacking machine, applied in the direction of pile separation, object separation, object stacking, etc., can solve the problems of double-layer paper, etc., and achieve the effect of convenient packaging work, novel conception and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

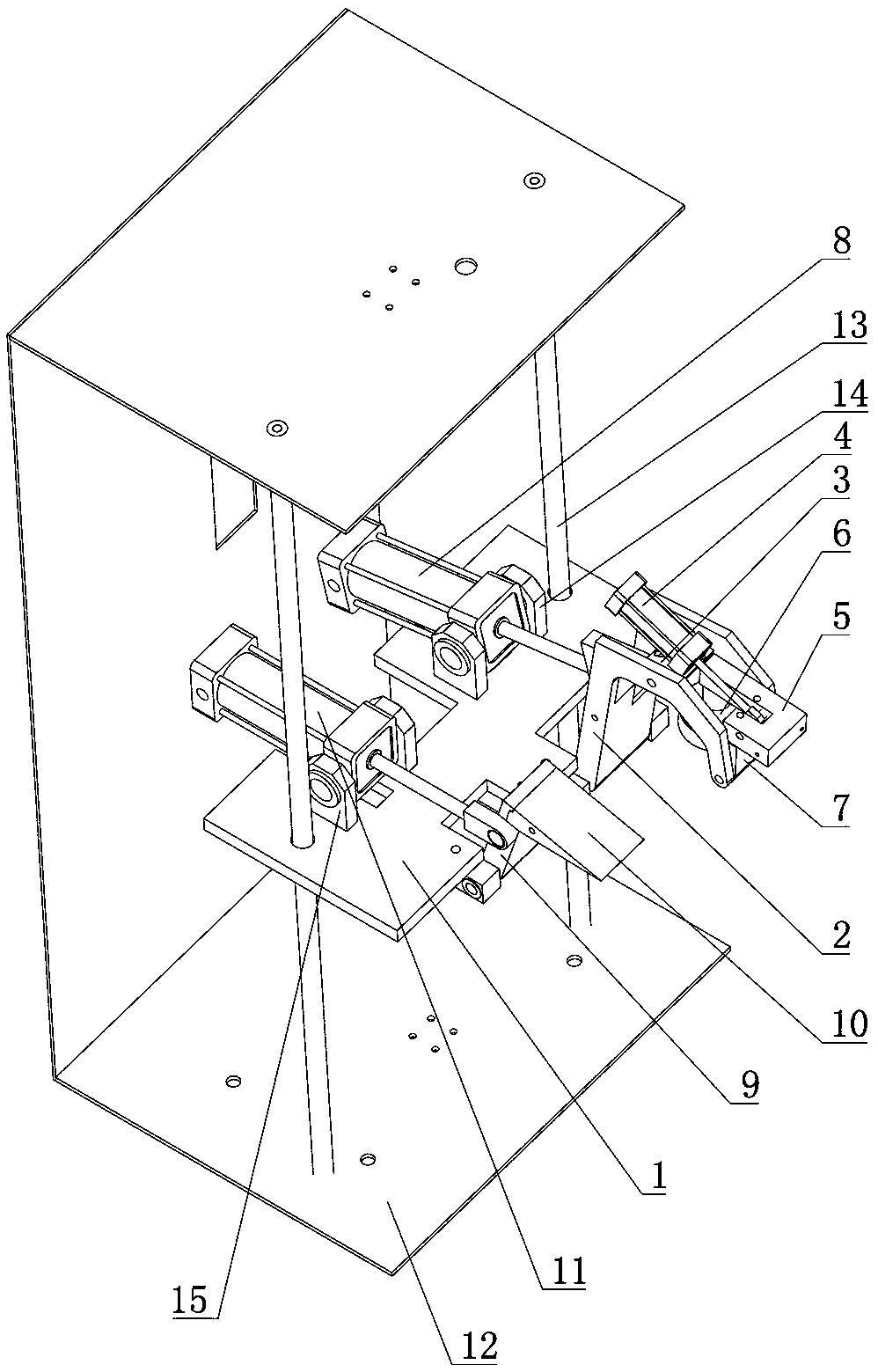

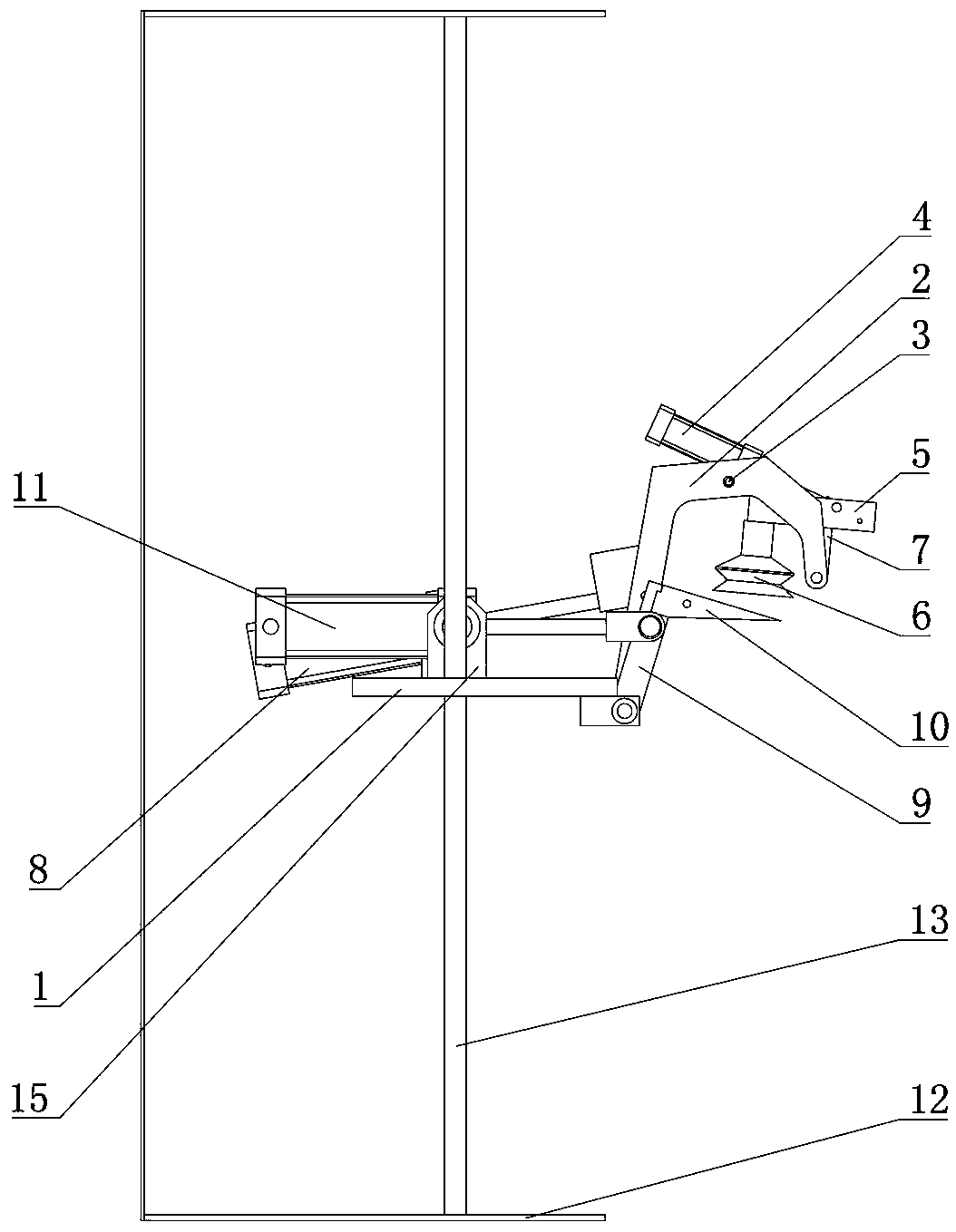

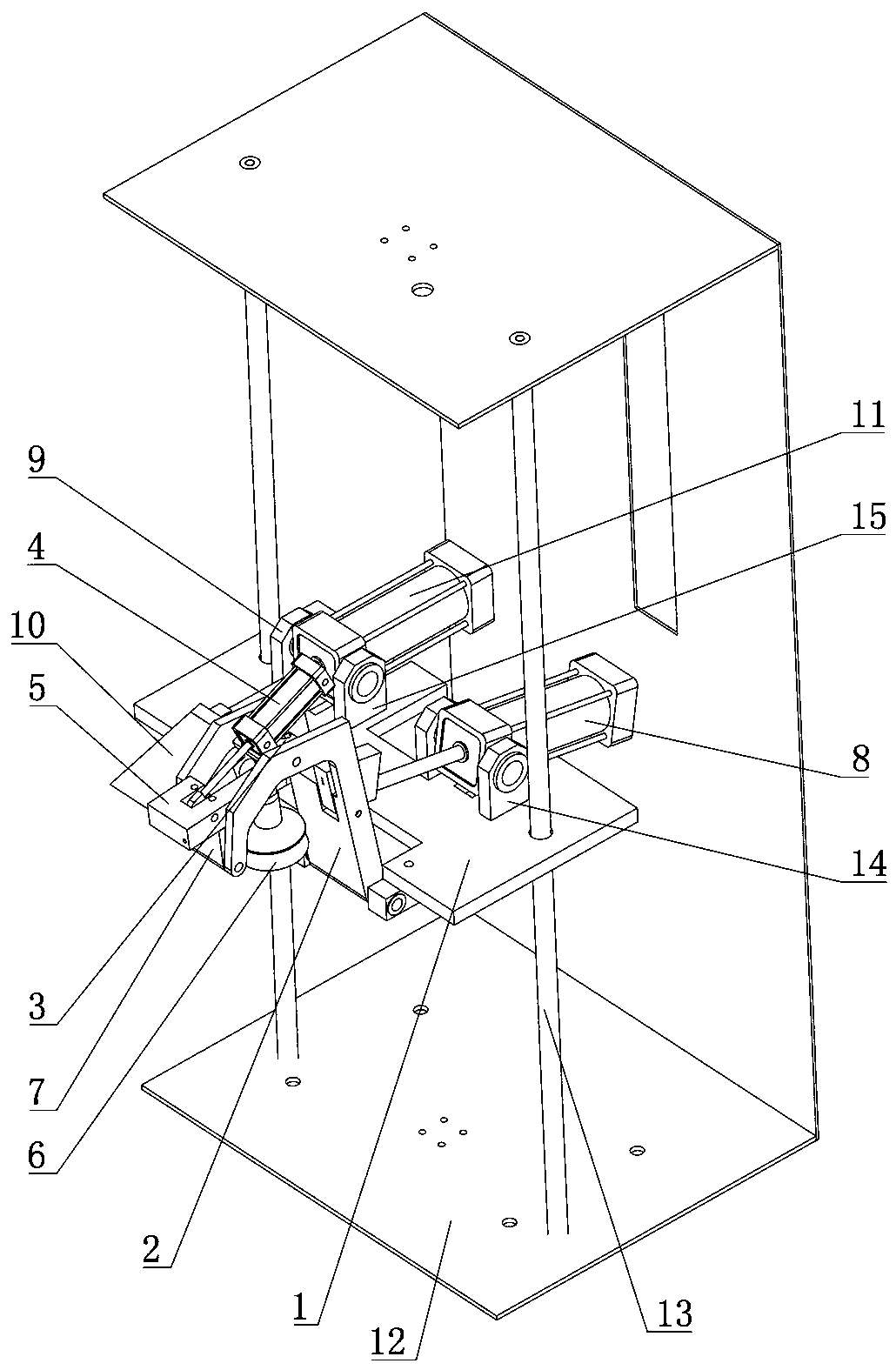

[0014] Depend on Figure 1 to Figure 3 Provided, the present invention includes a fixed disk 1, and the fixed disk 1 is provided with a paper suction mechanism and a paper separation mechanism;

[0015] The paper suction mechanism includes a first support arm 2 that is movably installed on the front end of the fixed disk 1. The first support arm 2 includes a base plate. Barb-shaped mounting arms are installed on the left and right sides of the base plate. There is a support plate 3, that is, the two ends of the support plate 3 are installed on the upper ends of the two mounting arms, the upper end of the support plate 3 is installed with a first hydraulic cylinder 4, and the middle part of the first hydraulic cylinder 4 is fixedly connected with the front end of the support plate 3, The front end of the first hydraulic cylinder 4 is hinged with a fixed plate 5, the width of the fixed plate 5 is less than the distance between the two mounting arms, the lower end of the fixed pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com