A fluid online debubbling device

A bubble and fluid technology, applied in the directions of foam dispersion/prevention, separation method, filtration and separation, etc., can solve the problems of low kinetic energy of oil in the return tank, system cavitation, and high oil viscosity, and achieves reduced floating resistance and simple structure. Reasonable, solubility reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

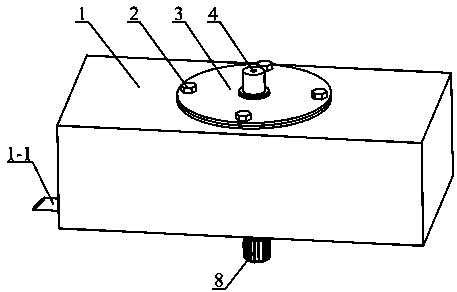

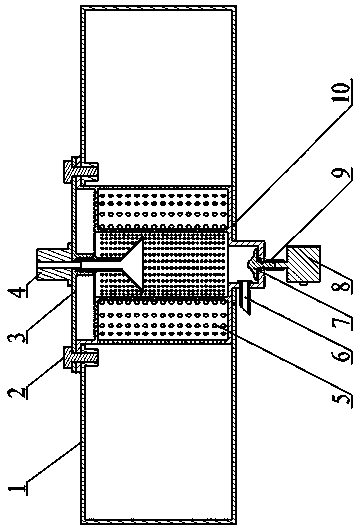

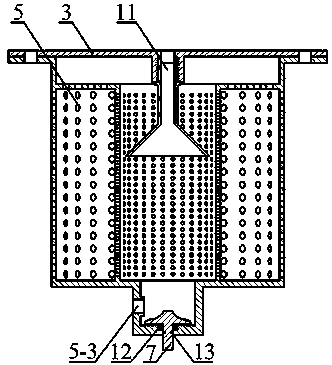

[0009] Such as Figure 1~Figure 6 As shown, the present invention is a fluid online debubbling device, including a separator, and the separator is composed of a top cover 3, a separation chamber 5, an impeller 7 and a gas collecting pipe 11; the separation chamber 5 is installed in the oil tank 1, and the top cover 3 Located on the top of the separation chamber 5, the bolt 2 is fixedly connected to the top cover 3, the separation chamber 5 and the oil tank 1; the suction port of the vacuum pump 4 is located in the top cover 3, and the gas collection pipe 11 is connected to the top cover 3; the bearing 12 is installed in the separation chamber 5, the impeller 7 is installed in the bearing 12; the motor 8 is connected to the impeller 7 through a coupling 9; the separation chamber 5 is composed of an inner cavity 5-1, an outer cavity 5-2 and an oil inlet 5-3.

[0010] Such as Figure 5 , Image 6 As shown, in the above-mentioned fluid online debubbling device, the volume of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com