Washing and drying integrated machine

An all-in-one, washing-drying technology, applied in household dryers, washing devices, textiles and papermaking, etc., can solve problems such as filter shedding, hidden dangers, and large vibration of the washer-drying integrated machine, so as to avoid hidden dangers of safety and improve operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

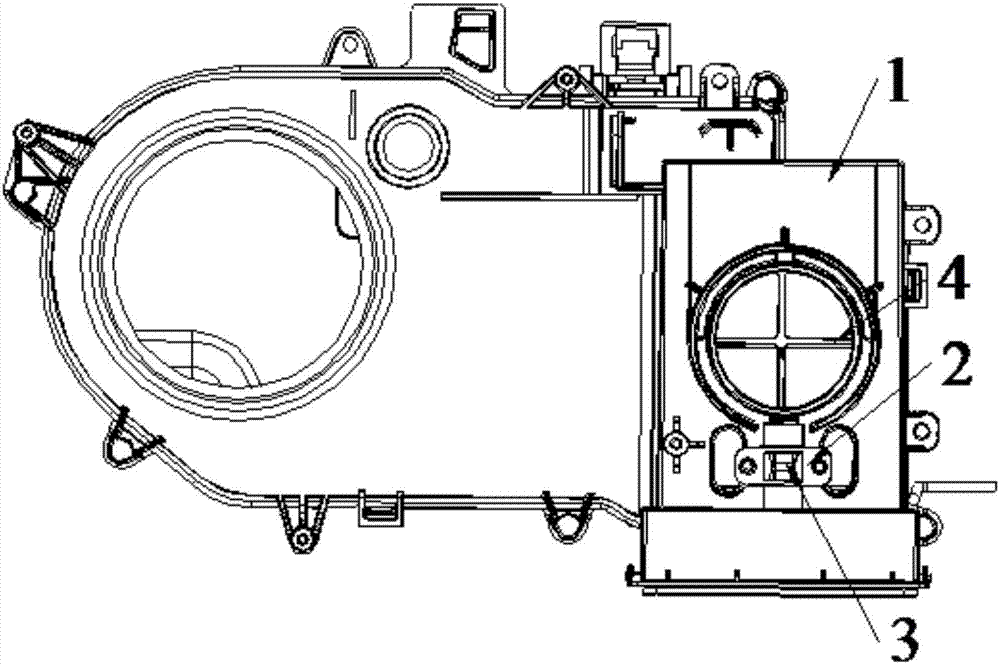

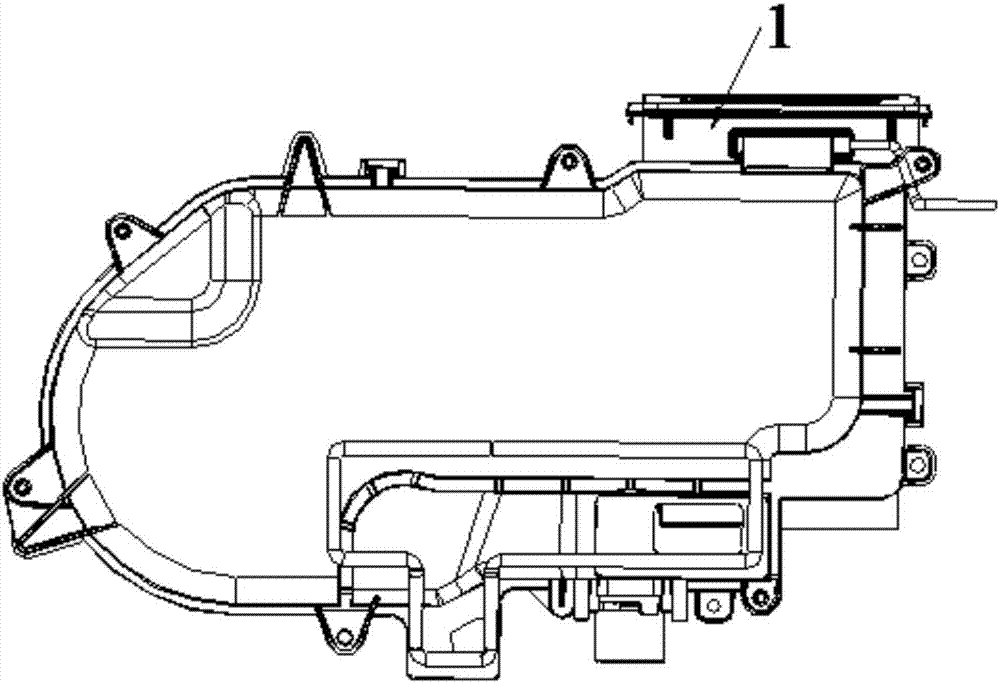

[0035] Such as Figure 1-5 , 11-13, this embodiment discloses an all-in-one washing and drying machine. A filter holder 1 is provided in the drying air duct of the washing and drying all-in-one machine. For the filter 4 for filtering, the filter holder 1 is provided with an elastically deformable protrusion 8, and the filter 4 is provided with a groove 9. During the installation process of the filter 4, the protrusion 8 is arranged on the outer periphery of the opening of the groove 9 The wall is deformed under pressure, and recovers after sliding into the groove 9, so that the filter 4 is clamped and fixed inside the filter bracket 1.

[0036] The all-in-one washer-dryer will generate relatively large vibrations during the working process, which will cause the filter on the all-in-one washer-dryer to fall off, thereby causing potential safety hazards and affecting the use of the all-in-one washer-dryer. Through the setting of the present invention, even when the all-in-one wa...

Embodiment 2

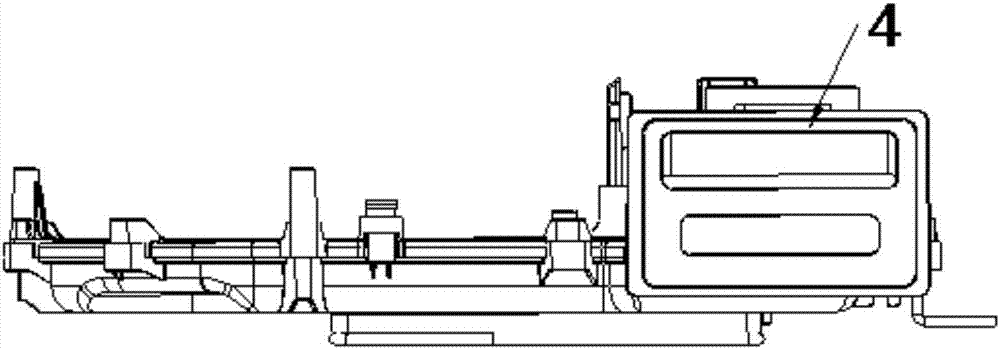

[0041] Such as Figure 6 , 8 As shown, the difference between this embodiment and Embodiment 1 is that the outside of the filter holder 1 is provided with a clip 3 extending along the push-pull direction of the filter 4, and the clip 3 is bent to form an inverted V-shaped structure, and the inverted V-shaped structure The two ends of the bottom are respectively bent toward the outer direction of the inverted V-shaped structure, and the extension part 6 extending along the push-pull direction of the filter 4 is formed. The filter bracket 1 is provided with a through hole 12, and the top of the inverted V-shaped structure passes through the through hole. The hole 12 is provided inside the filter holder 1 to form a protrusion 8, the extension part 6 is arranged outside the filter holder 1, and is limited and clamped with the outer peripheral wall of the through hole 12, and at least one extension part 6 can move along the filter 4 The push-pull direction moves for the protrusion...

Embodiment 3

[0046] Such as Figure 10 , 14 As shown, the difference between this embodiment and Embodiments 1 and 2 is that the end of the extension part 6 is bent toward the protruding direction of the inverted V-shaped structure to form a support part 7, and the end of the support part 7 is in contact with the outer peripheral wall surface of the through hole 12. Supporting and conflicting with each other, the filter bracket 1 is arranged on one side of the extension part 6, and the other side of the extension part 6 is provided with a mounting bracket 2. The support conflicts, so that the clamping member 3 is clamped and fixed.

[0047] The above arrangement makes there be a gap between the extension part 6 and the outer peripheral wall of the through hole 12 , and at the same time makes the extension part 6 fixed in the axial direction of the through hole 12 , which improves the reliability of the connection of the clip 3 .

[0048] Specifically, a protruding screw column 11 is prov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap