Double-axis invisible hinge

A technology of invisible hinges and shaft holes, which is applied to hinges with pins, door/window accessories, folding panels, etc., can solve the problems of not meeting the actual use requirements and poor aesthetics, so as to prevent external pollution and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

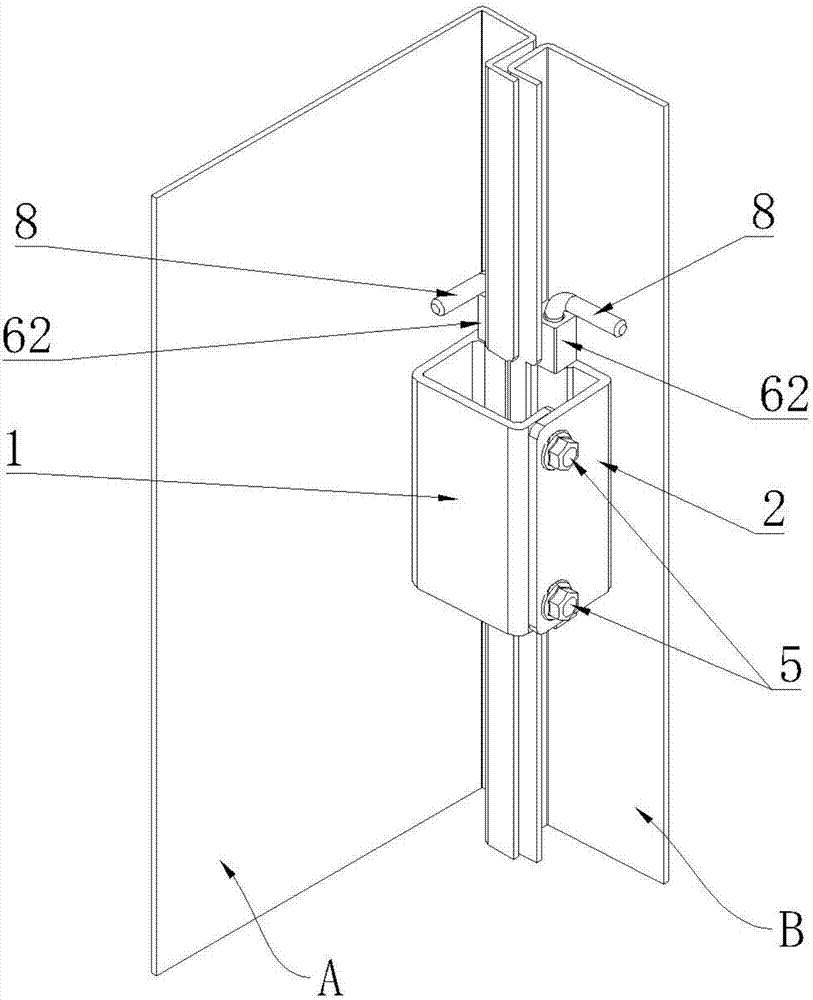

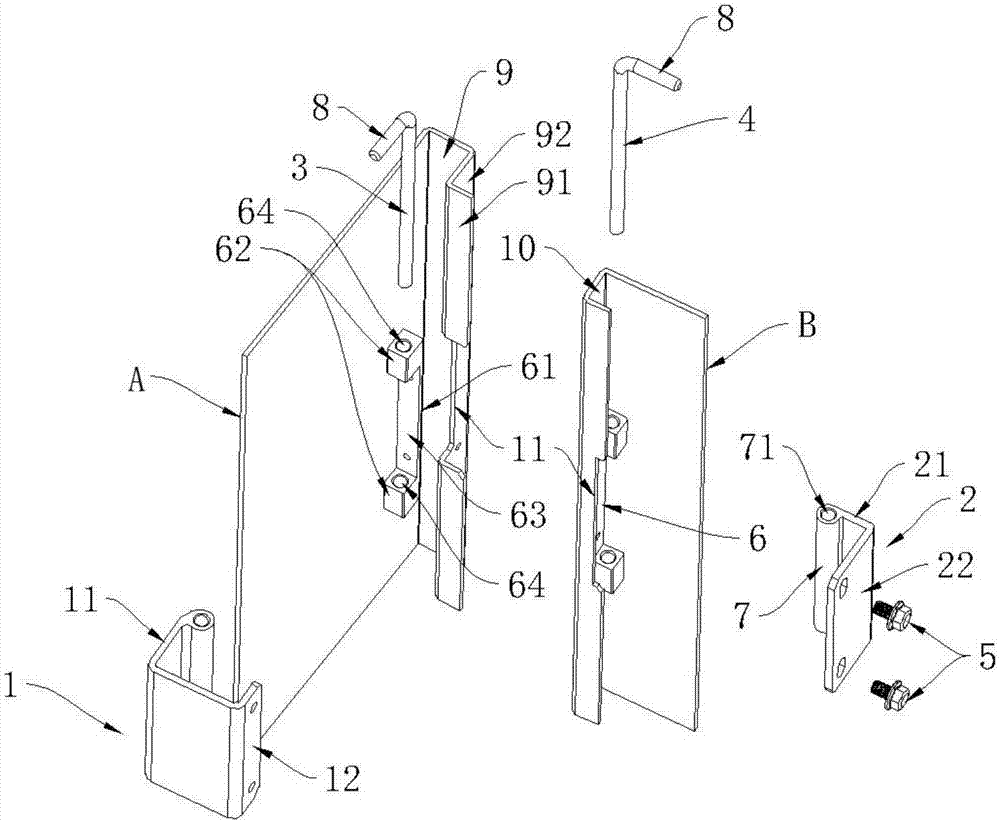

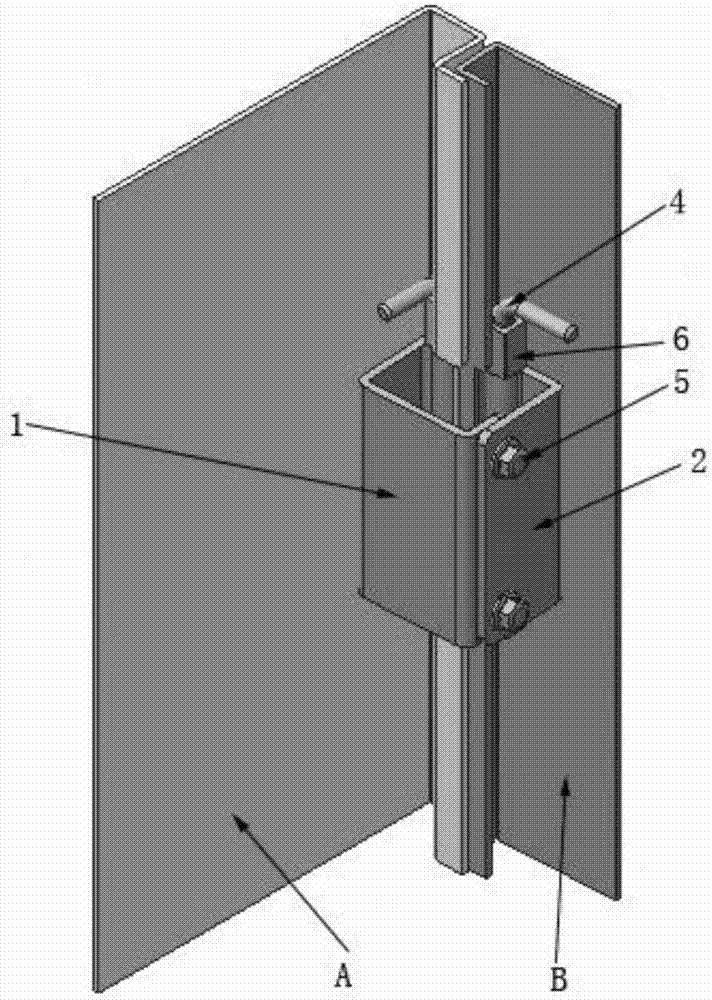

[0017] See figure 1 and figure 2 , the two-axis invisible hinge of the present invention, which includes a first hinge 1 and a second hinge 2, the first hinge 1 is groove-shaped, the second hinge 2 is L-shaped, and the first hinge is groove-shaped An outer groove wall 11 of 1 is rotatably mounted on the cabinet body A of the cabinet through the first hinge shaft 3, and an outer wall 21 of the L-shaped second hinge 2 is rotatably installed through the second hinge shaft 4. Installed on the cabinet door panel B, the first hinge shaft 3 and the second hinge shaft 4 are parallel to each other, the other outer groove wall surface 12 of the first hinge 1 and the other outer wall surface 22 of the second hinge are fixed by screws 5 , the first hinge 1 and the second hinge 2 are combined to form a hollow column structure with a corner end notch.

[0018] On the cabinet body A of the cabinet and on the door panel B of the cabinet, there are respectively fixed shaft sleeves 6 with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com