A kind of solidification molding method of L-shaped plate composite material parts

A composite material and solidification molding technology, which is applied in the field of composite material molding, can solve the problems of non-universality and ignore the rebound deformation of composite material components, and achieve the effect of improving bending and torsion resistance and splitting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Give the L-shaped plate example below to introduce the curing molding method of the present invention:

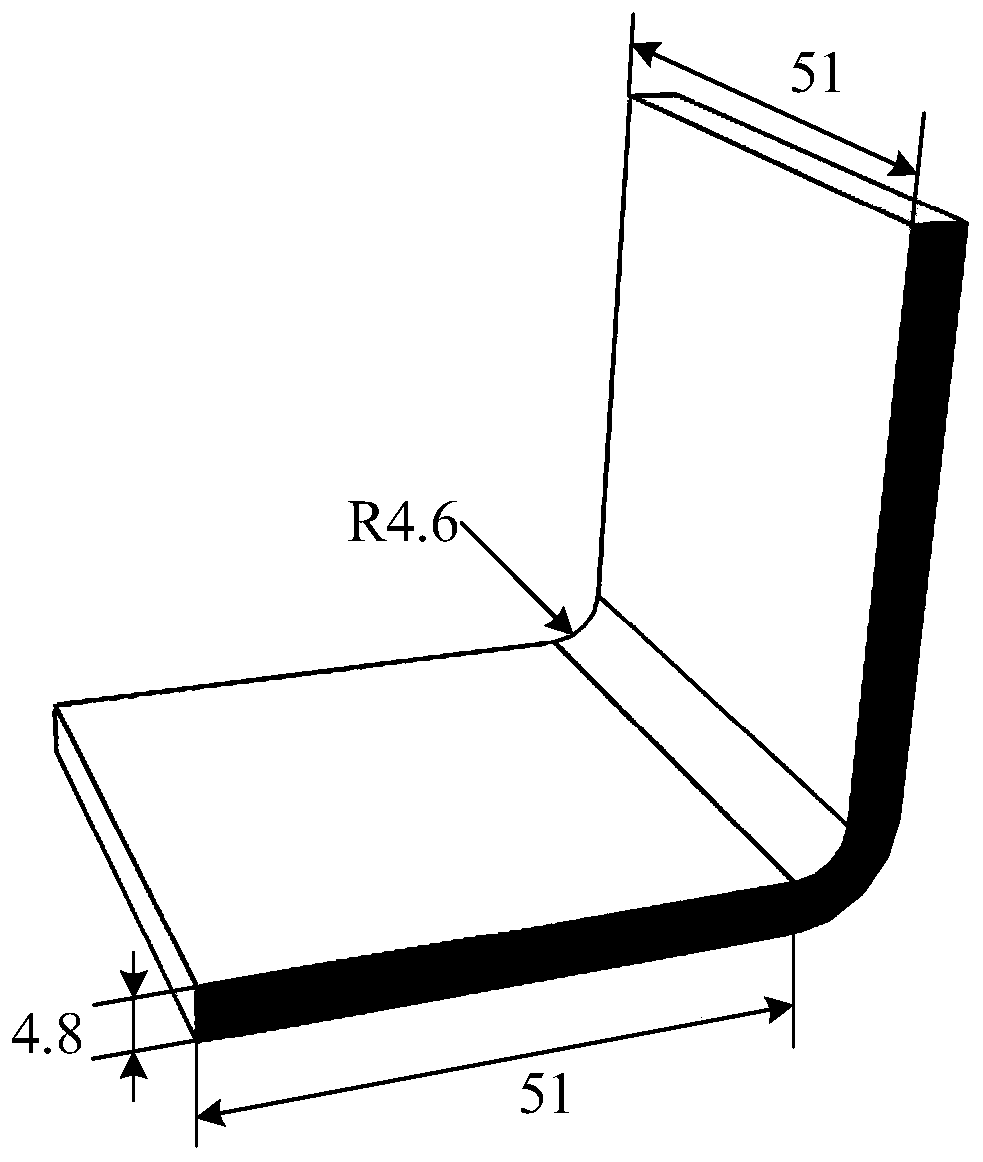

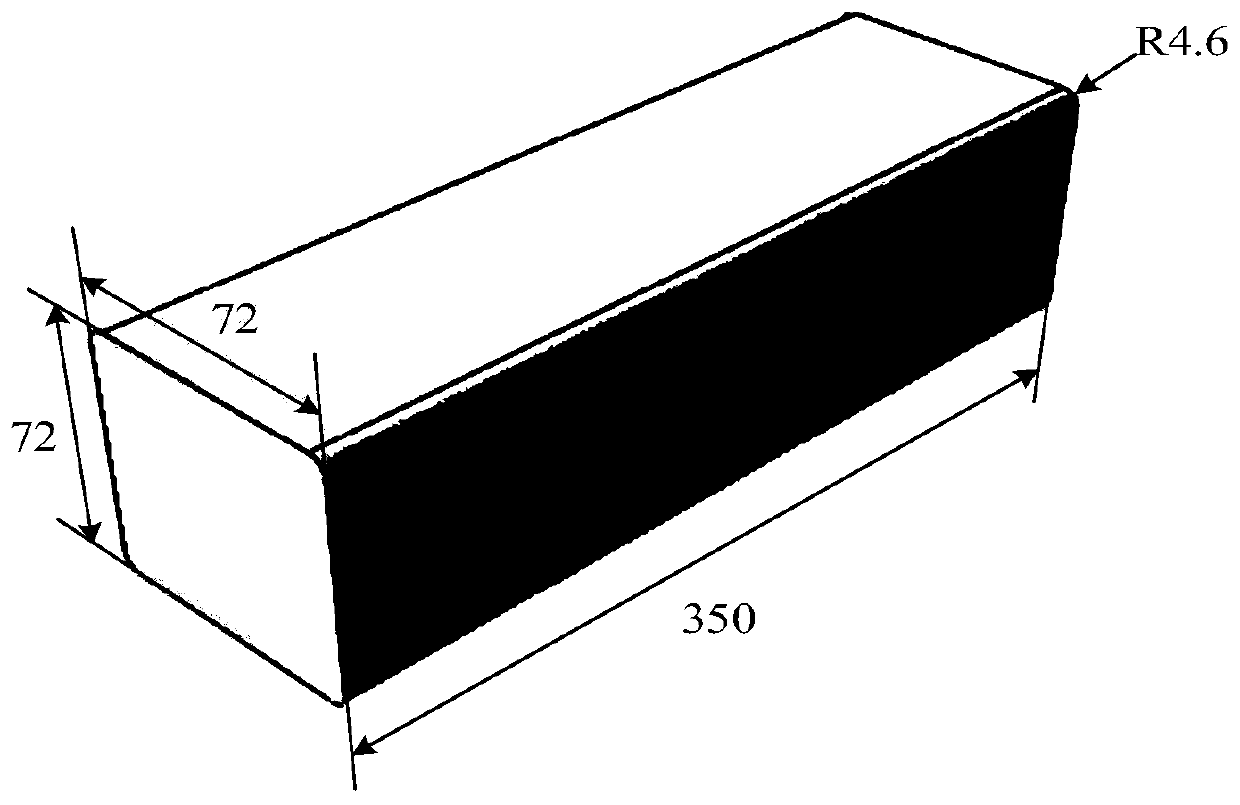

[0056] The dimensions of composite L-shaped members are as figure 1 As shown, the thickness of the L-shaped plate is 4.8 mm, and the L-shaped plate includes a horizontal plate and a vertical plate, and the length of the horizontal plate and the vertical plate is both 51 mm. The width of the horizontal plate and the vertical plate are both 51mm, and the radius R of the fillet at the junction of the horizontal plate and the vertical plate is 4.6mm. The size of the mold is as figure 2 As shown, the L-shaped member is composed of 8 layers of single-layer composite materials, the thickness of each layer is 0.2mm, and the size information of the mold is 72×72×350mm 3 . The assembly relationship between the mold and the L-shaped component of the composite material is as follows: image 3 As shown, only one-half of the model was built due to the symmetry of the mold and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com