Reinforced concrete prefabricated slab

A technology of reinforced concrete and prefabricated panels, applied in covering/lining, construction, building construction, etc., to achieve high production efficiency, resource saving, and sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

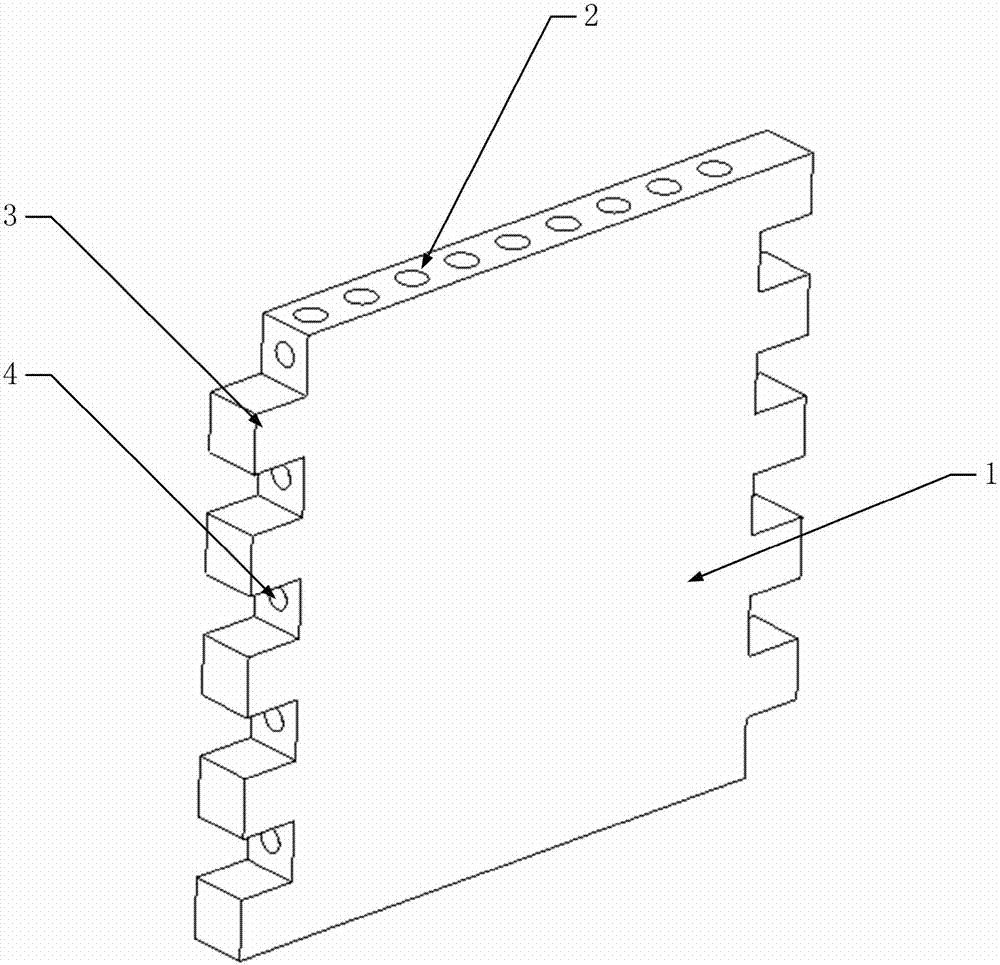

[0015] Such as figure 1 As shown, a reinforced concrete prefabricated slab is provided with longitudinal holes 2 parallel to the surface, the longitudinal edges of the prefabricated slab 1 are provided with transverse grooves 3 at intervals, and the prefabricated slab 1 is provided with transverse holes 4 parallel to the surface , the transverse hole 4 is arranged at the center of the transverse groove 3 , and the transverse hole 4 intersects the longitudinal hole 2 .

[0016] The transverse grooves 3 of the prefabricated panels 1 are alternately arranged on the two longitudinal edges, and two prefabricated panels 1 are fitted together through the transverse grooves 3 .

[0017] The prefabricated panels 1 can be combined into L-shaped, cross-shaped wall columns a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com