Hollow precast concrete slab and manufacturing method thereof

A technology of prefabricated concrete and hollow slabs, applied in the manufacture of tools, building components, building materials, etc., can solve problems affecting normal use, affecting mechanical performance, easy to crack, etc., to achieve convenient connection, high production efficiency, and high degree of standardization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

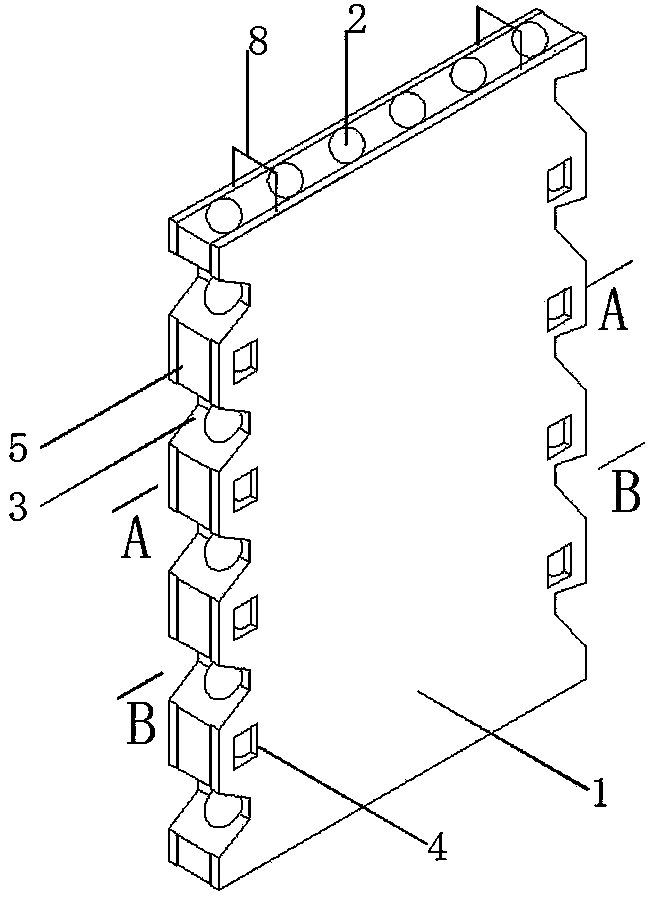

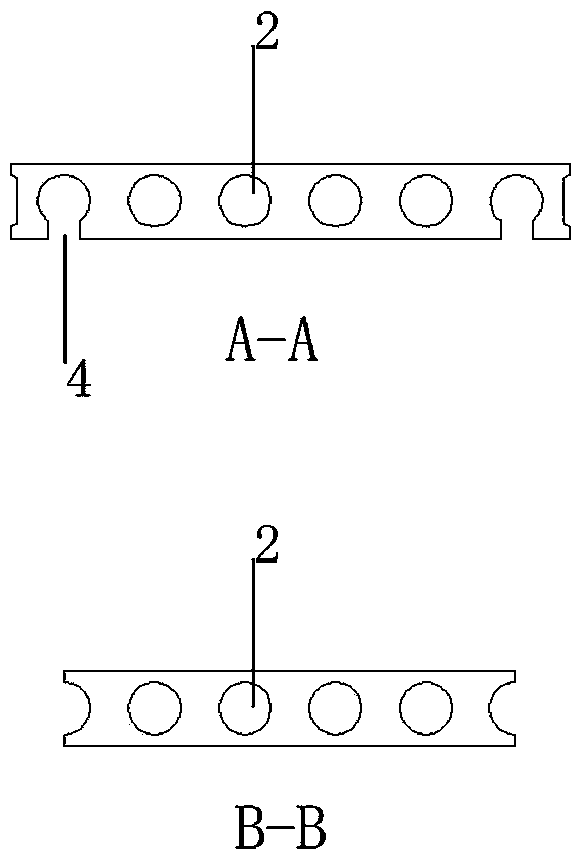

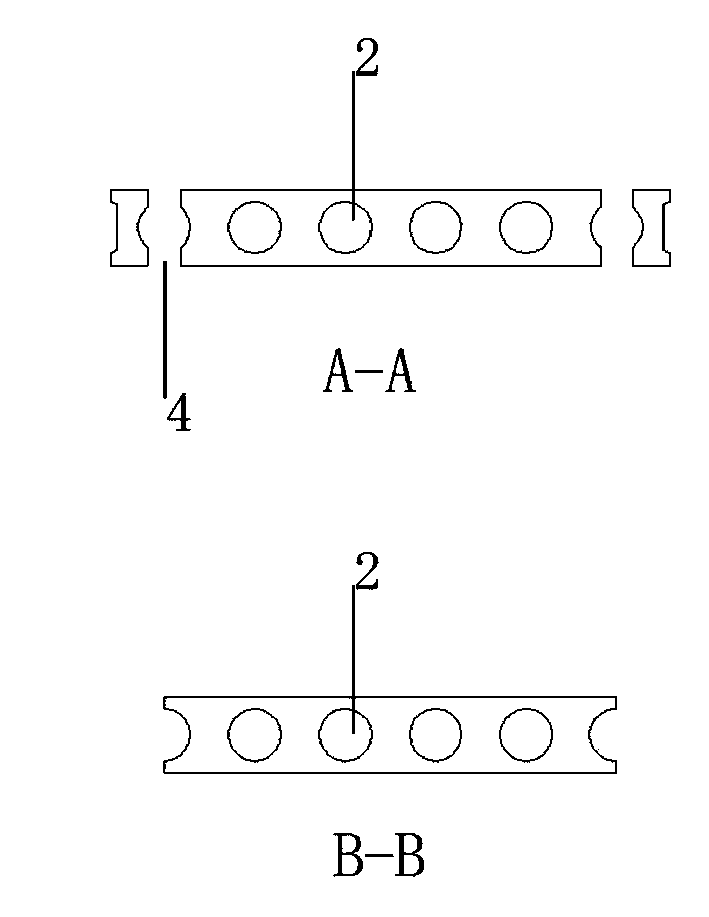

[0037] Embodiment 1 is a kind of prefabricated concrete hollow slab, such as figure 1 , figure 2 , image 3 As shown, the precast concrete hollow slab 1 is provided with a number of longitudinal through holes 2 parallel to each other along the length direction, the longitudinal edges are provided with transverse grooves 3 intersecting at least one longitudinal hole at intervals, and the protrusions 5 between the transverse grooves and the grooves Arranged in a staggered manner; the protrusions 5 between the transverse grooves are provided with plate surface holes 4 connected to the longitudinal holes, and the plate surface holes 4 are provided on one side of the precast concrete hollow slab, such as figure 2 , or both sides of the plate, such as image 3 ; The prefabricated concrete hollow slab 1 is provided with an installation ring 8 . The cross-section of the longitudinal hole is circular, rectangular, etc., and the diameter or side length is 60mm to 340mm. The side v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com