Method, device and vehicle for controlling tire burnout caused by vehicle turning in situ

An in-situ steering and control device technology, applied in the field of vehicles, can solve problems such as inability to guarantee, driver distraction, and cumbersome operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

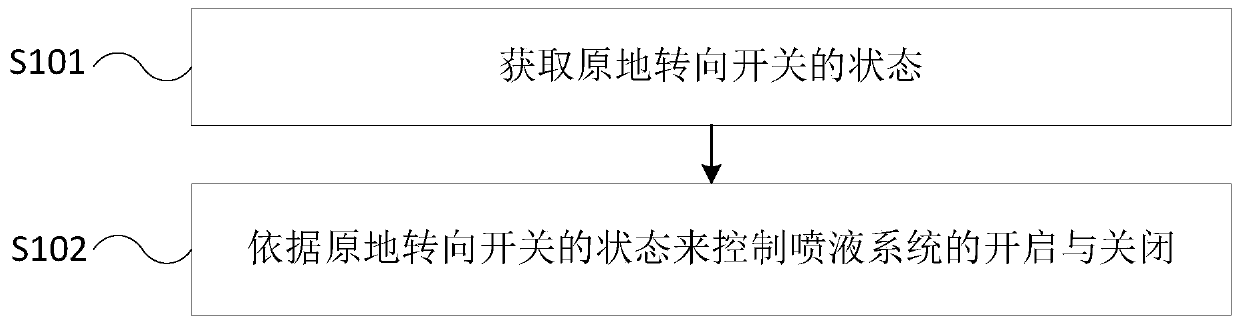

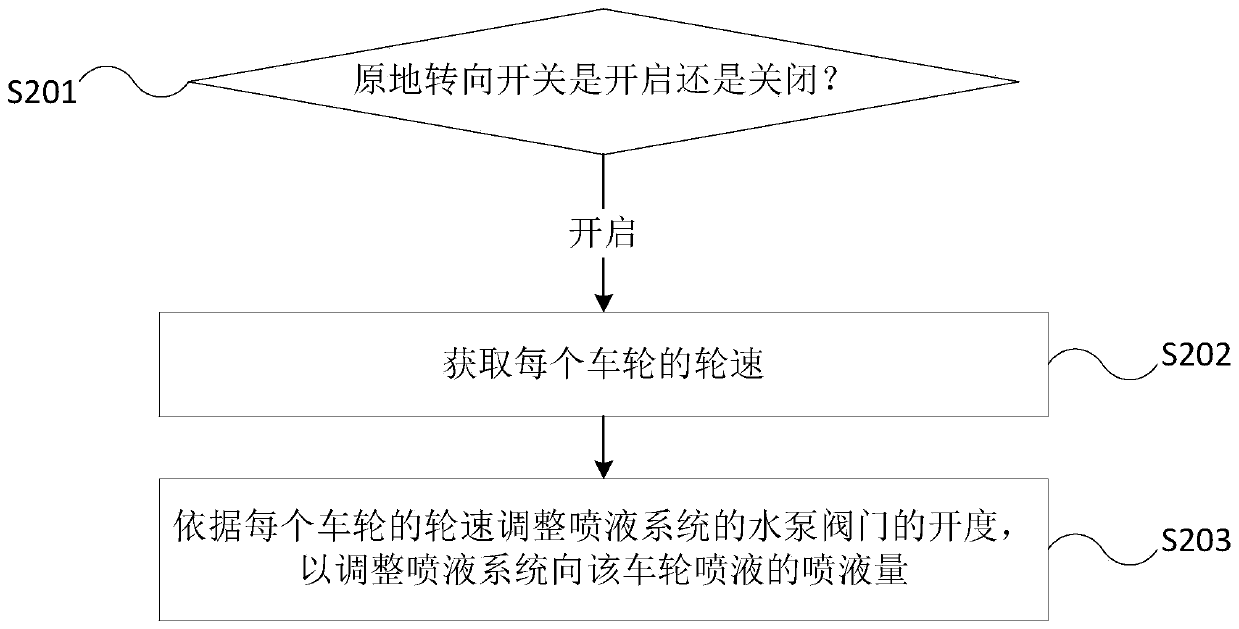

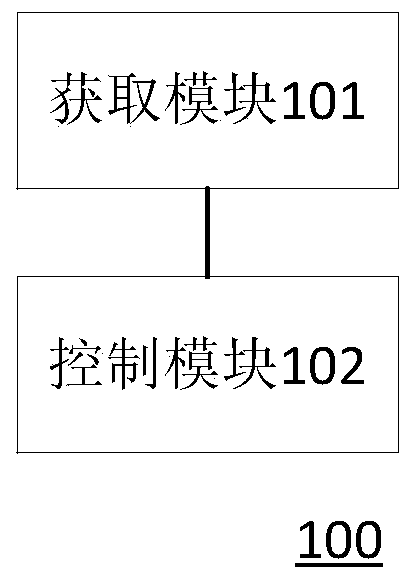

Method used

Image

Examples

Embodiment Construction

[0047] Specific embodiments of the present disclosure will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present disclosure, and are not intended to limit the present disclosure.

[0048] First of all, introduce the liquid spray system mentioned in the embodiment of the present disclosure, its specific structure is as follows Figure 5 shown. The liquid spray system 200 mainly includes a liquid spray pot 201 , an electric water pump 202 , a nozzle 203 , a water pump valve 204 and other components. The liquid spray pot 201 is connected to the electric water pump 202 through a pipeline, and the electric water pump 202 is also connected to a nozzle 203 through a pipeline, and the nozzle 203 is arranged facing the tire. The electric water pump 202 starts up after receiving the starting command sent by the whole vehicle controller of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com