GRC (Glass Fiber Reinforced Cement) plate hoisting auxiliary installation device

A technology of installation device and board hoisting, which is applied in the direction of winch device, portable lifting device, clockwork mechanism, etc., which can solve the problems of inconvenient GRC board installation, poor economy, long preparation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

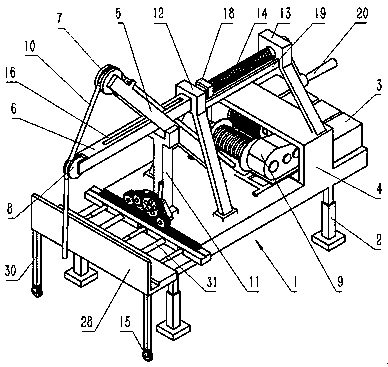

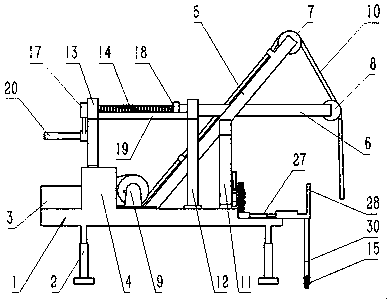

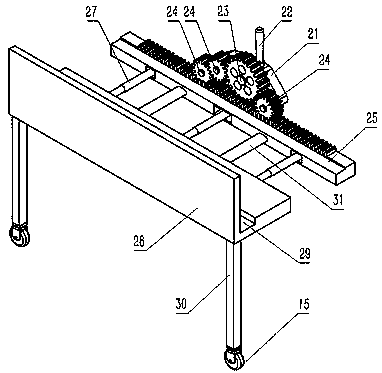

[0036] In order to clearly illustrate the technical characteristics of this solution, the following describes the solution through specific implementations.

[0037] This embodiment is an auxiliary installation device for hanging and pulling a GRC board. It includes a base frame 1. The base frame 1 includes a rectangular plate parallel to the ground. The front end of the rectangular plate is close to the rectangular plate and an extension plate is arranged. The bottom surface of the extension plate is flush with the rectangular plate. , The height of the extension board is smaller than the rectangular board, the top surface of the base frame 1 is fixedly provided with a "door" type support seat 4, and the support seat 4 is fixedly connected to the third bracket 13;

[0038] The bottom of the underframe 1 is provided with feet 2, the underframe 1 is provided with a hoist 9, and the first hoist 5 is fixed on one side of the hoist 9. The first hoist 5 is a square pole and is inclined t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com