Modularized steel-aluminum mixed auxiliary automobile frame structure

A sub-frame, modular technology, applied in the direction of the connection between the upper structure, the lower structure, the upper structure sub-assembly, etc., can solve the problems of the inability to flexibly realize the platform requirements, the high cost of the middle beam mold, and reduce the development cost. Cost, change cost is low, the effect of improving the generalization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

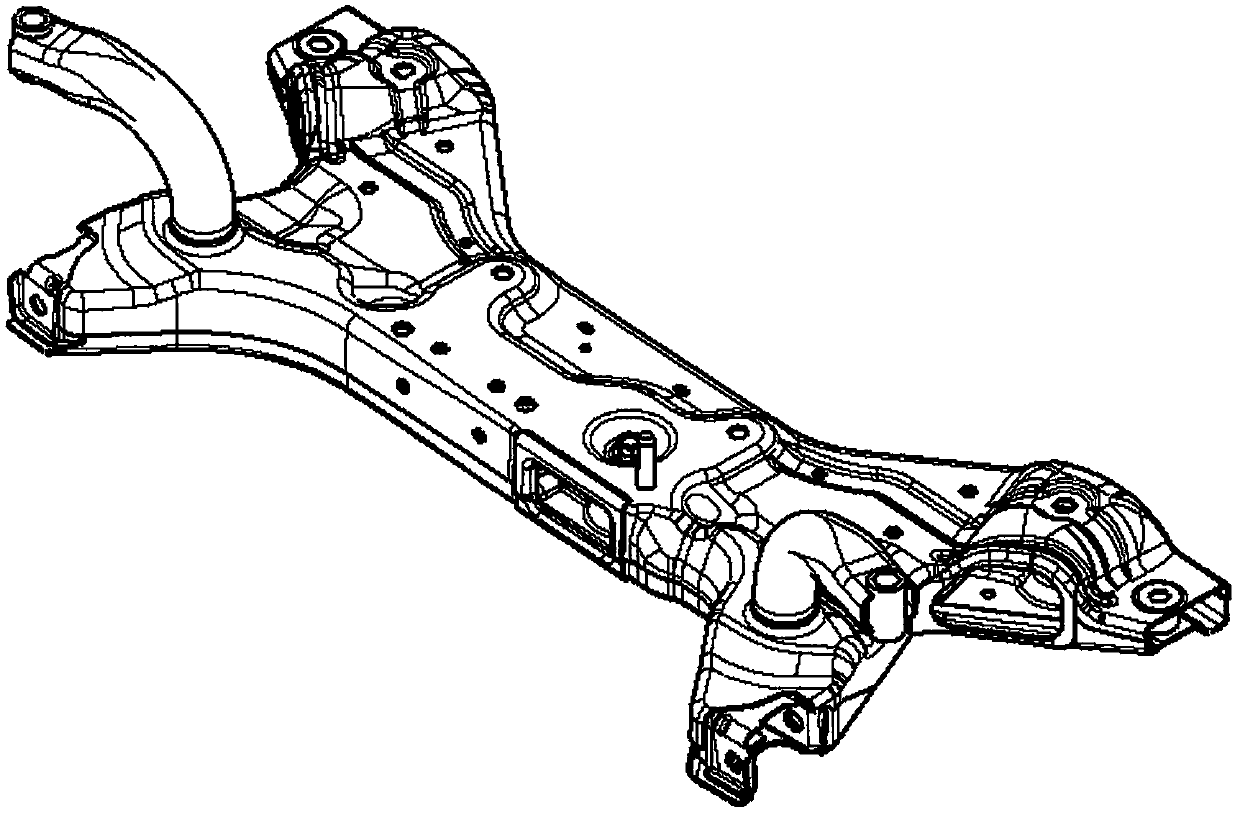

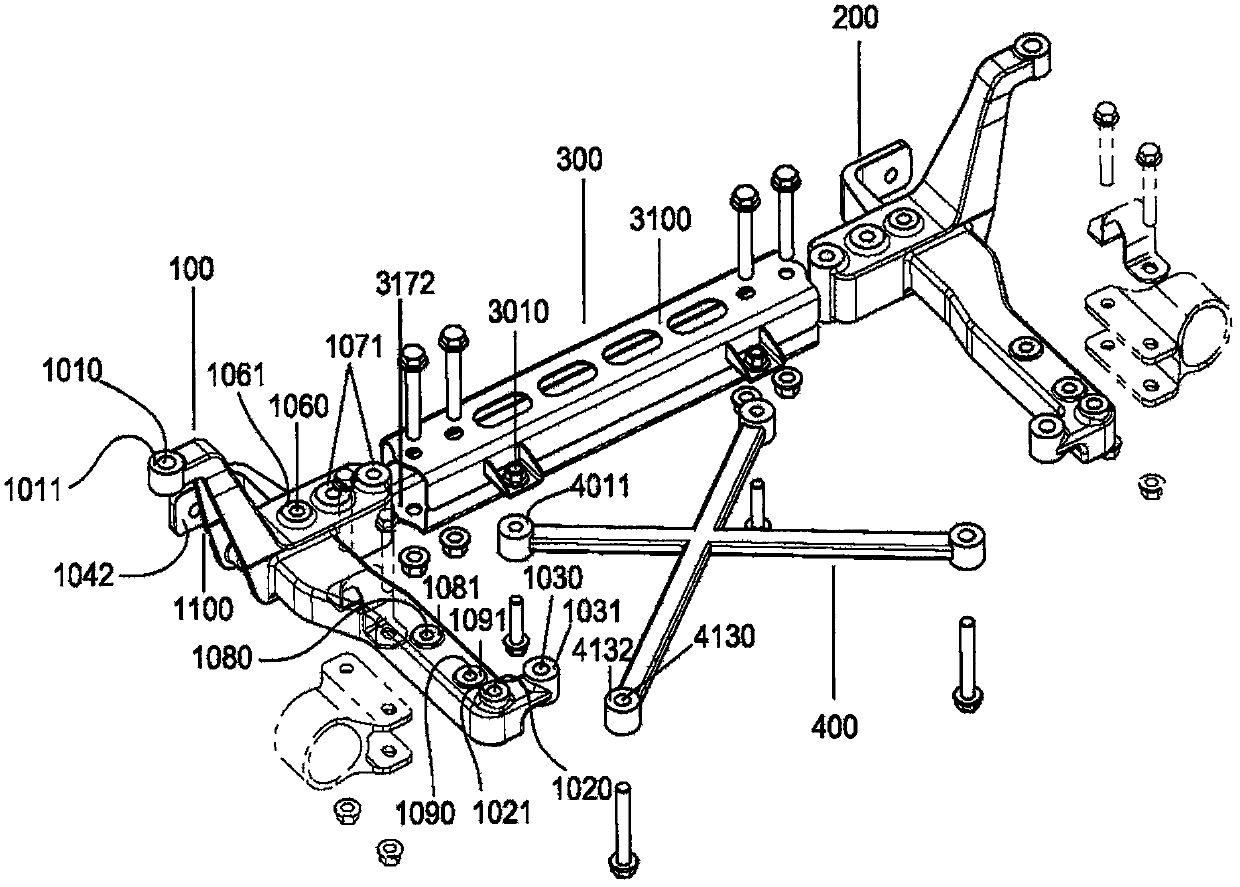

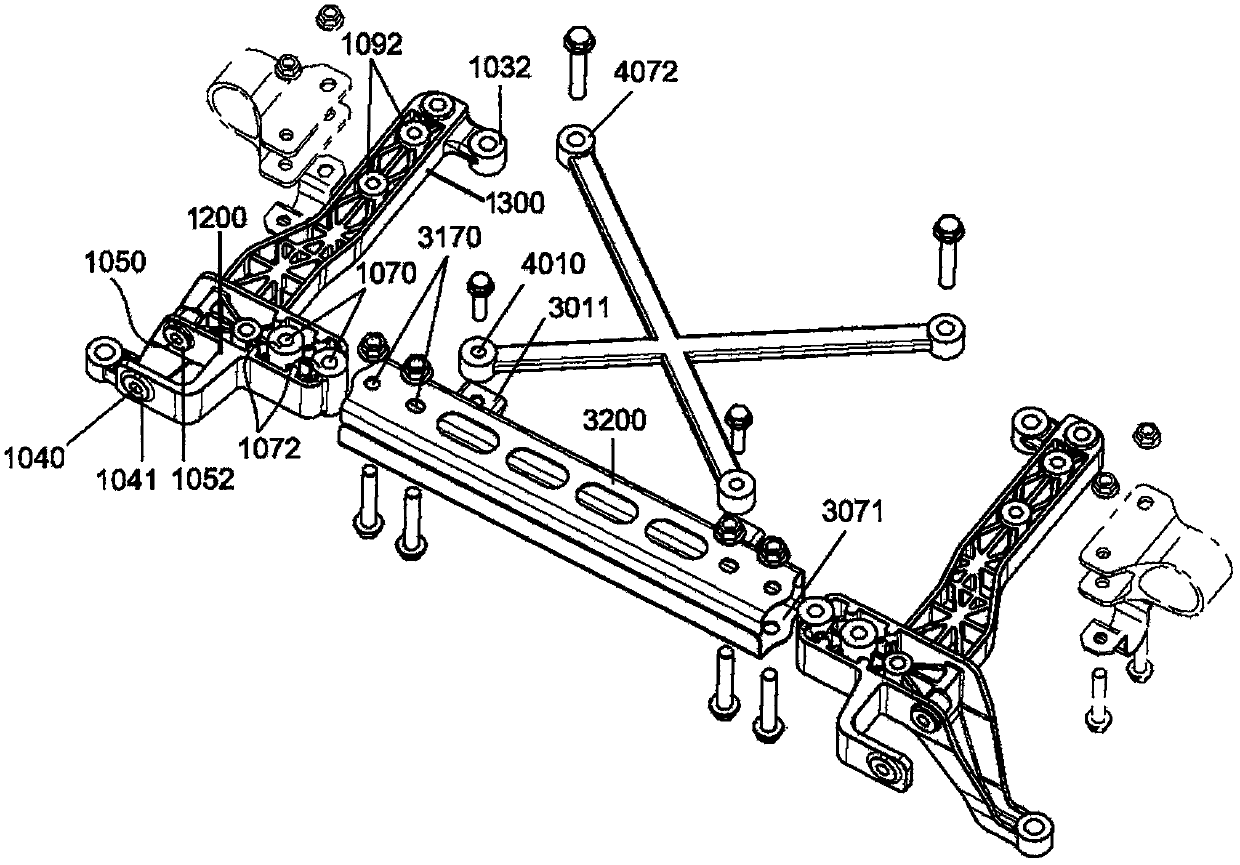

[0024] Such as Figure 2-6 As shown, the modularized steel-aluminum hybrid subframe structure of this embodiment includes four parts: a left beam module 100 , a right beam module 200 , a cross beam module 300 and a reinforcing bracket 400 . The beam module 300 is a hollow beam structure formed by welding an upper plate 3100 with a flange and a lower plate 3200 with a flange at the flange, and the upper plate and the lower plate of the beam module can be punched according to circumstances There are several lightening holes, and the upper plate and the lower plate are stamped from high-strength steel plates. The left end and the right end of the beam module 300 are respectively provided with at least two mounting holes 3170 passing through the upper plate and the lower plate, and the matching surfaces with the left beam module are 3171 and 3172; the left beam module 100 and the right beam module 200 It is a left-right symmetrical structure, the left beam module and the right be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com