Framework for board loading

A frame and plate technology, applied in the field of plate loading frame, can solve the problems of plate damage, lack of wall panel equipment, inconvenience of construction personnel, etc., to prevent damage, improve work quality, and reduce redundant manual processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

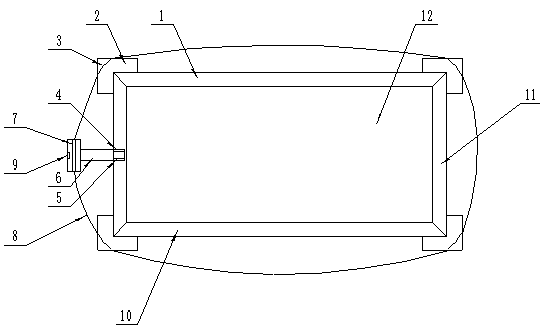

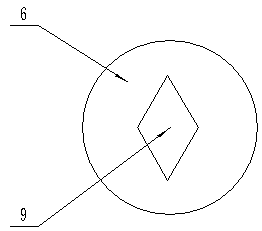

[0013] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown, a frame for plate loading includes a protective frame (1), and protective corner sleeves (2) are set at the four corners of the protective frame (1), and the side surfaces of the plurality of protective corner sleeves (2) are all open There is an arc-shaped groove (3), the center of one side surface of the protective frame (1) is provided with a turning groove (4), the inner surface of the turning groove (4) is provided with an internal thread (5), and the turning groove (4) A bolt (6) is inserted inside, and one end of the bolt (6) is provided with a wire slot (7), and a winding wire (8) is inserted inside the sleeve groove (7), and the wire winding (8) respectively set on a plurality of arc-shaped grooves (3), the center position of one end side surface of the bolt (6) is provided with a groove (9); the protective frame consists of a set of horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com