Paper angle bead blank fixing ring with lubricating function

A technology of fixing rings and paper corner protectors, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of affecting work efficiency, inconsistent adding frequency, breakage of paper corner protector blanks, etc., and achieves reduction in production The effect on the accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

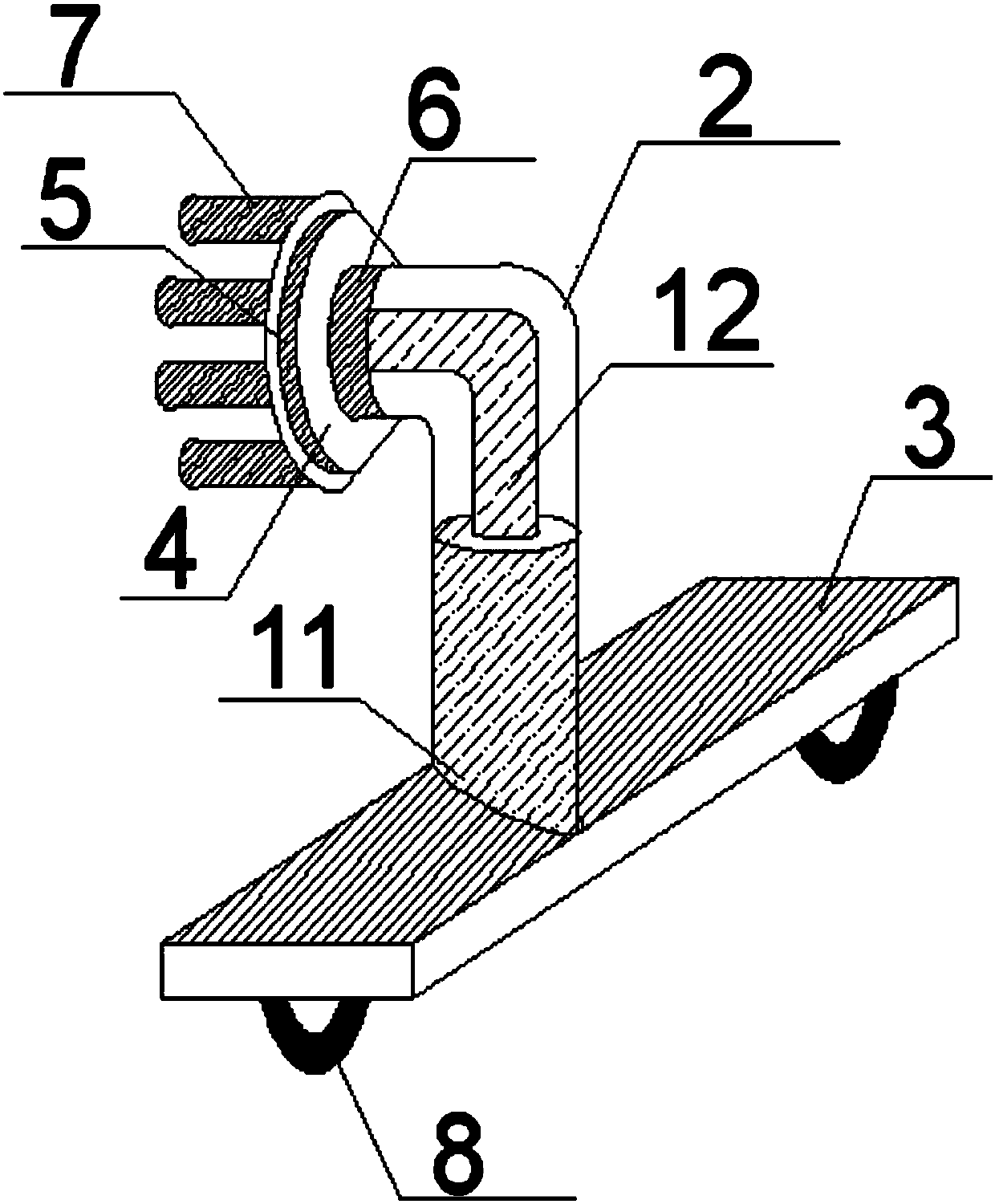

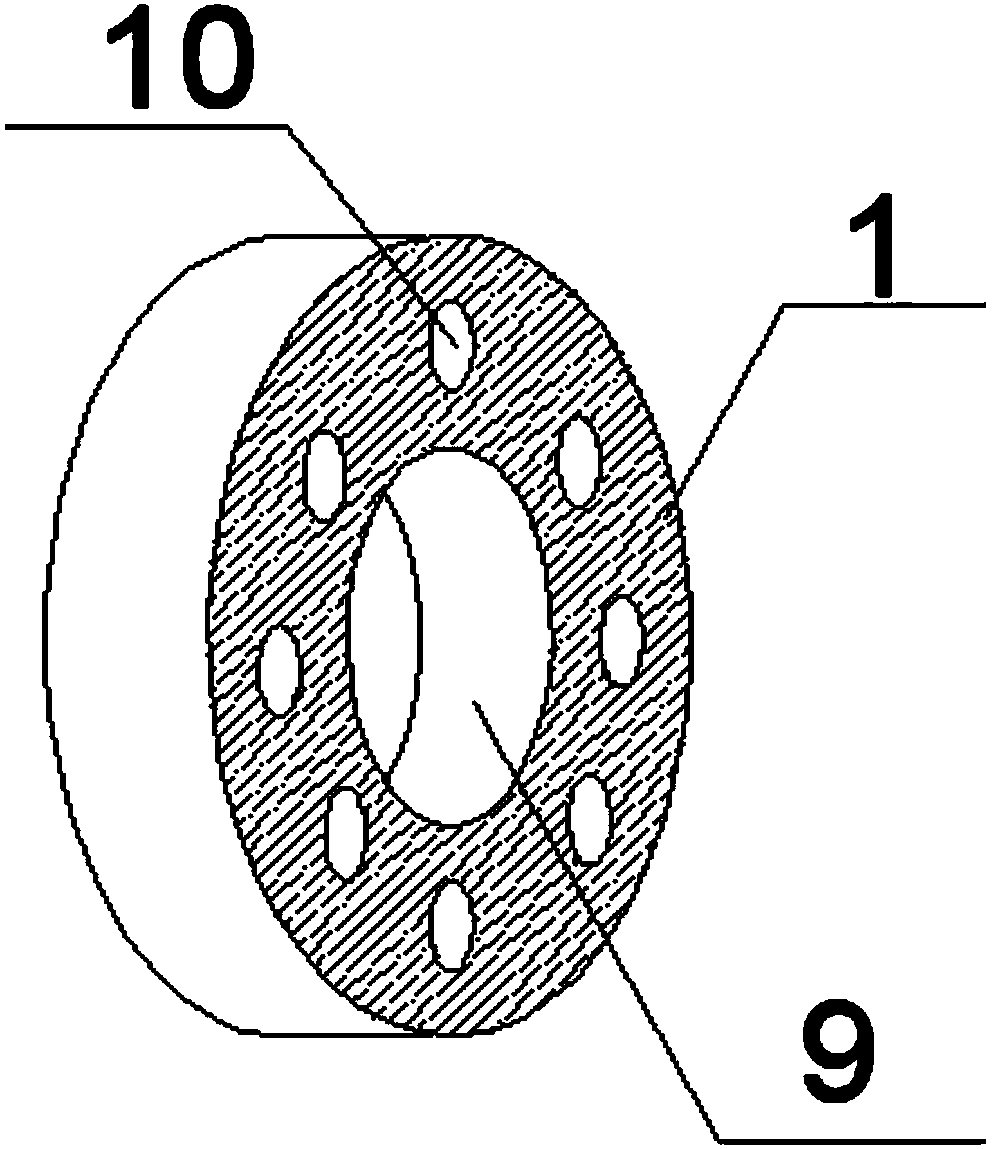

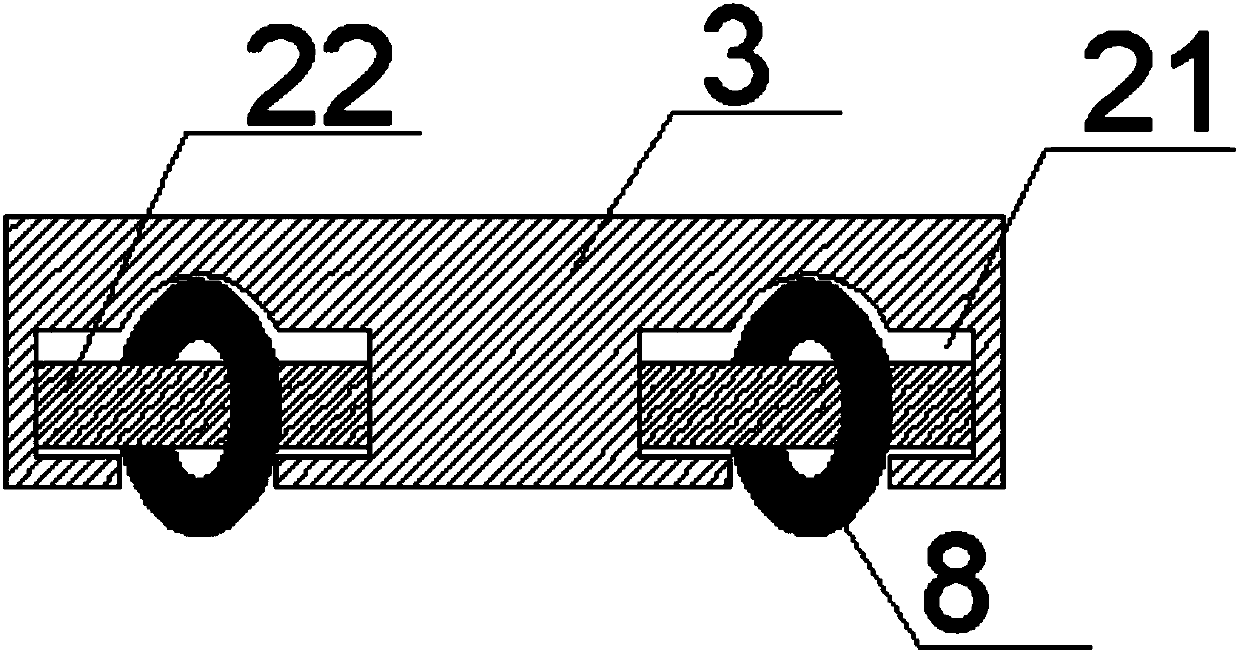

[0023] The fixed pin 7 is set in the pin hole 10, the blank fixed ring 1 is fixed on the turntable 5, the power is turned on, the rotating motor 6 works and drives the turntable 5 to rotate, the blank fixed ring 1 rotates and realizes that the paper corner protector blank plate is in the blank fixed ring 1 winding.

[0024] The oil pipe 12 communicates with the rotating electrical machine 6, and the oil pipe 12 sucks the lubricating oil in the oil storage tank 11 and spreads it evenly on the rotating electrical machine 6, so as to realize the automatic addition of lubricating oil.

[0025] The oil storage tank 11 includes an oil tank 13 and an oil guide box 14, the surface edge of the oil tank 13 is provided with a fixing groove 15 for the oil guide box, and a number of oil outlet holes 17 are uniformly distributed on the surface of the oil tank 13. The bottom of the box 14 is provided with an oil guiding box positioning ring 16, and a plurality of connecting pipes 18 are unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap