Mixed batch inspection method and system for oral liquid logistics operation

An inspection method and inspection system technology, which is applied to the mixed batch inspection method and system field in the oral liquid logistics operation, can solve the problems of uncheckable, production accidents, untraceable mixed batch production of washing, blowing, filling and sealing production lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

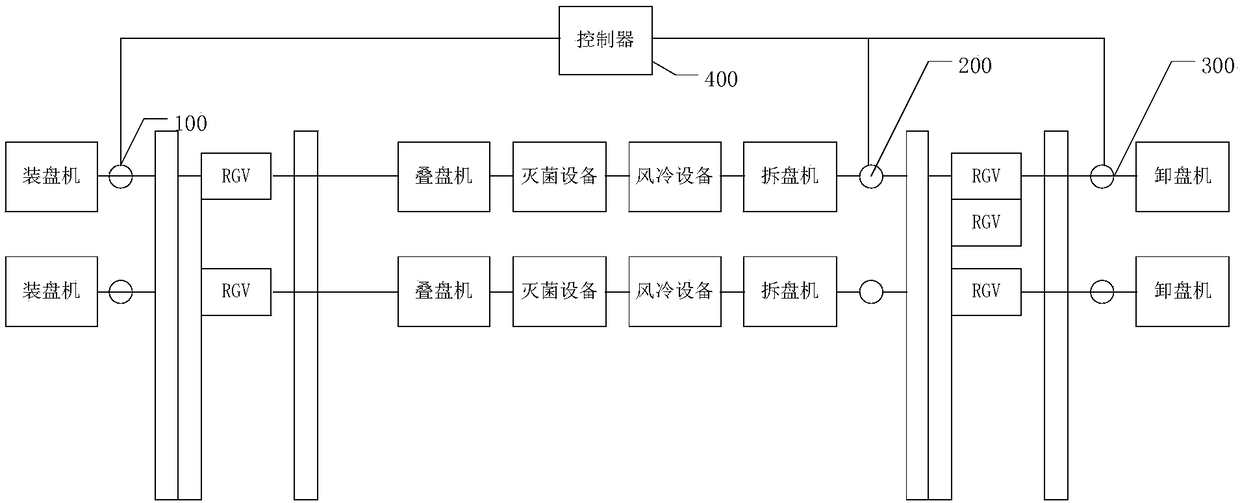

[0030] The core of the present invention is to provide a mixed-batch inspection method and system for oral liquid flow operation, so as to reduce the probability of production accidents.

[0031] In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

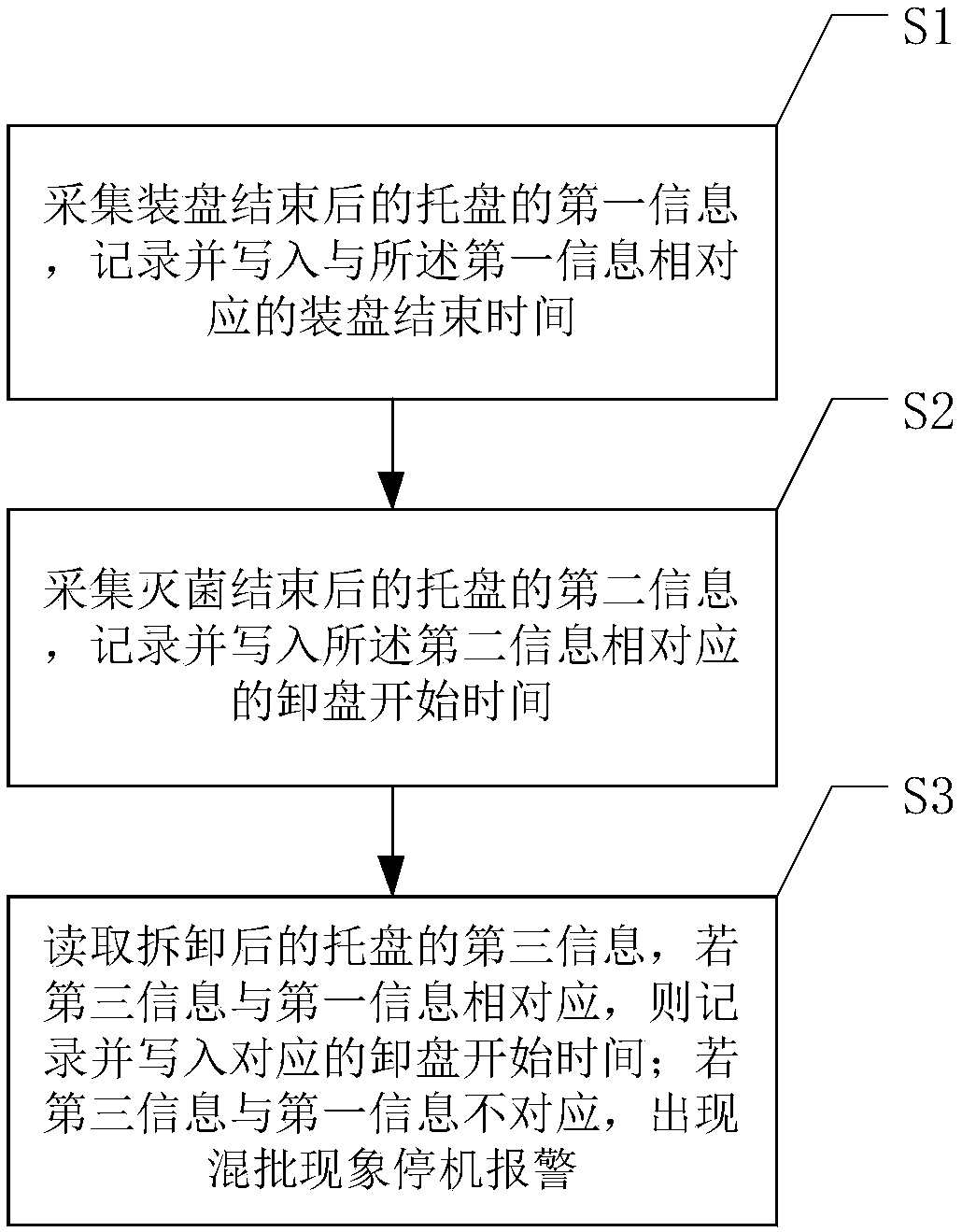

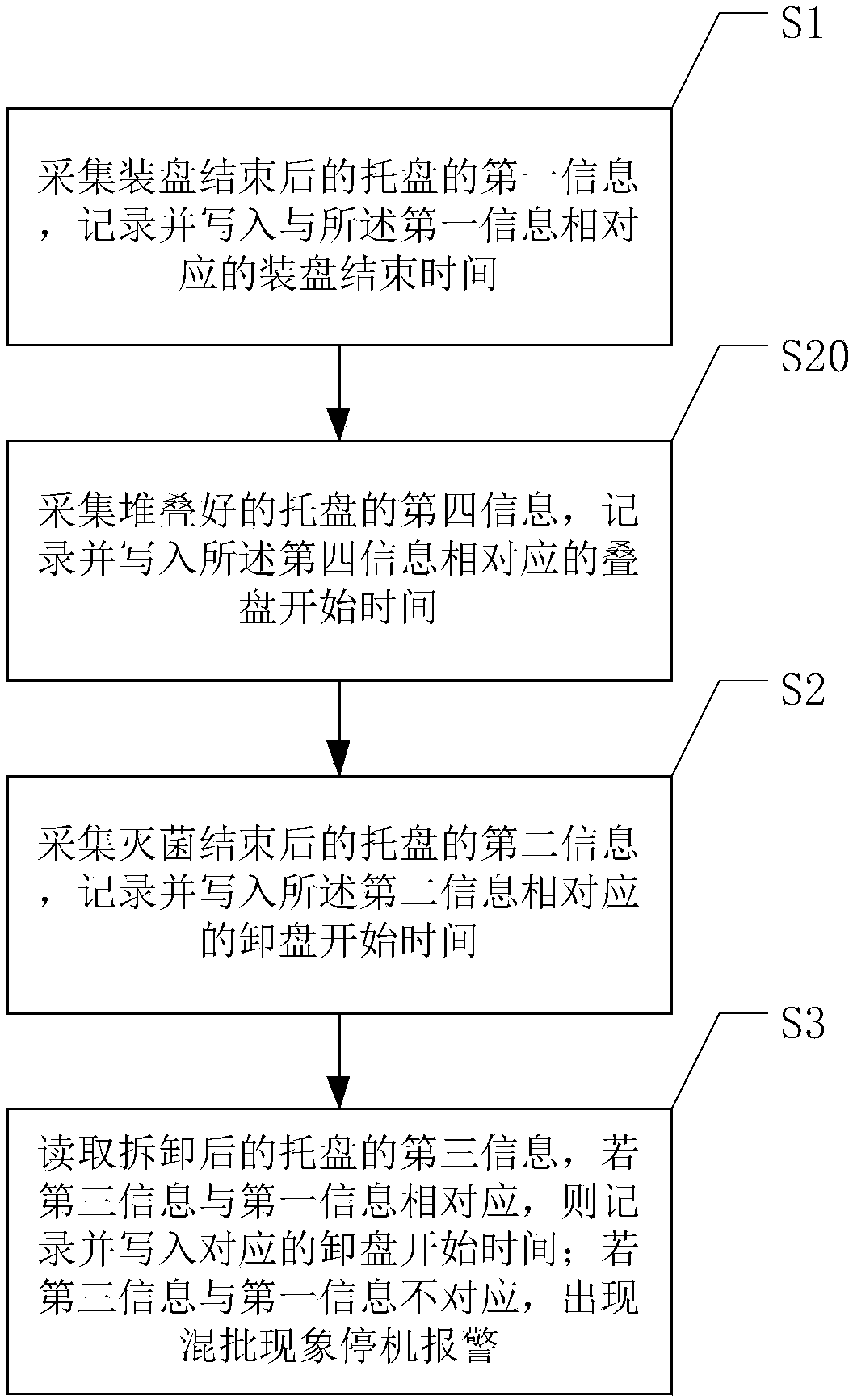

[0032] see figure 1 , the mixed batch inspection method used in the oral liquid logistics operation of the embodiment of the present invention, comprising:

[0033] Step S1: Collect the first information of the tray after loading, record and write the end time of loading corresponding to the first information; the first information of the tray requiring instructions includes the number of the tray, barcode or two-dimensional Code and other information for easy identification. The end time of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap