Fire door glued intelligent production system and its operation method

A technology of intelligent production and fire doors, applied in chemical instruments and methods, connecting components, material gluing, etc., can solve problems that do not mention automatic processing, intelligent production systems, etc., to achieve intelligent and unmanned , Improve product consistency and stability, improve the effect of intelligent level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

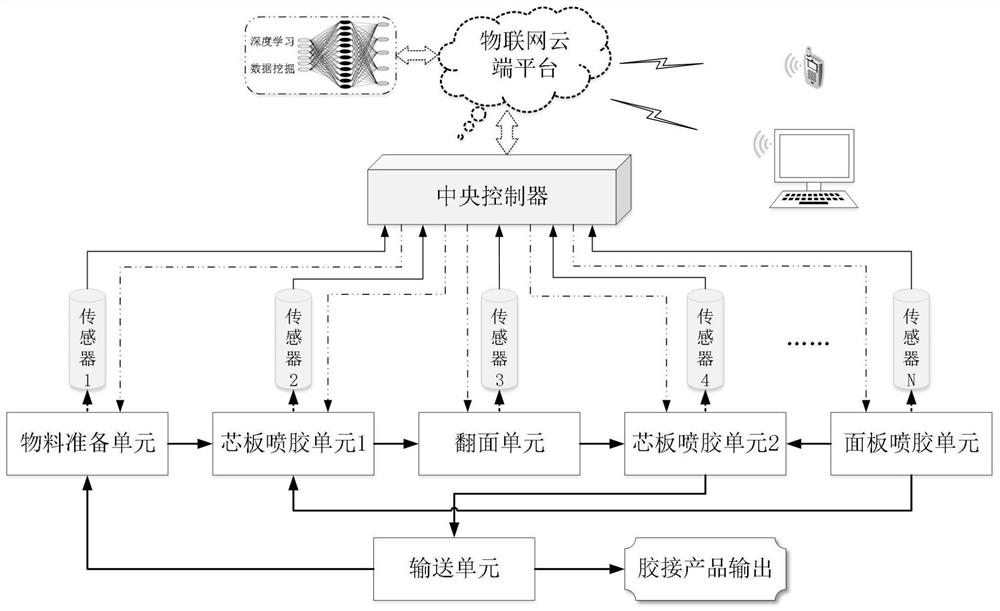

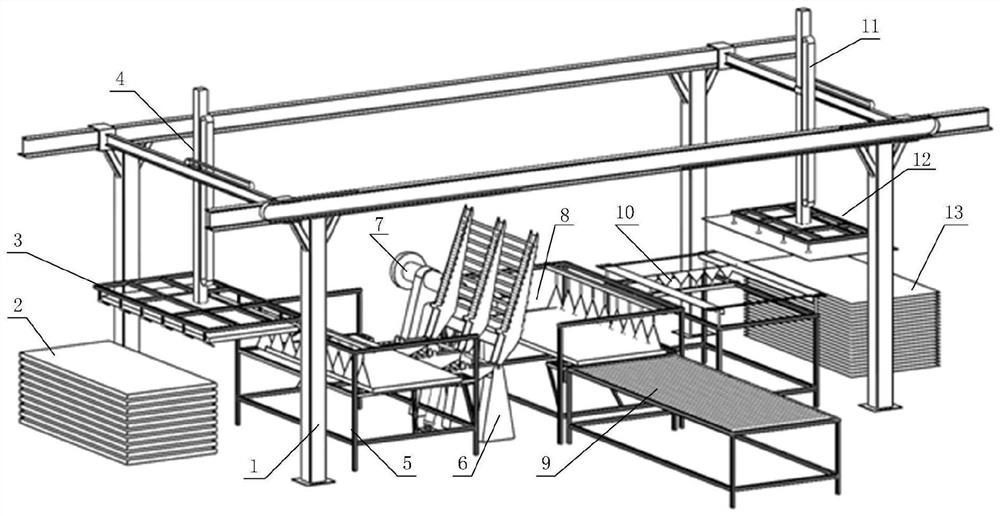

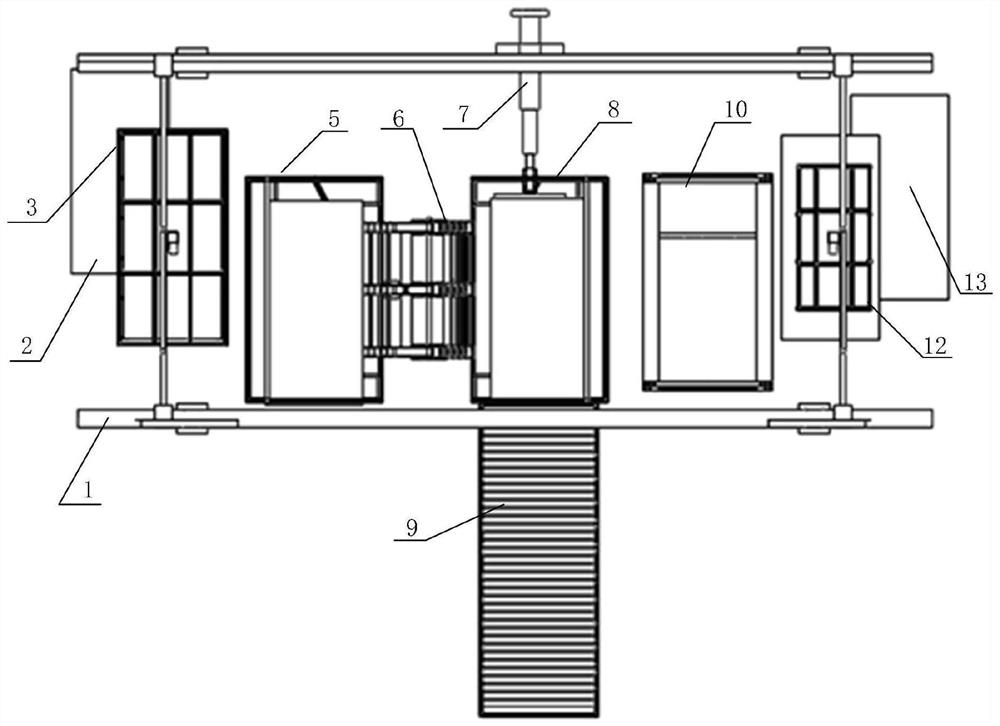

[0058] see Figure 1 to Figure 6 , an intelligent production system for fireproof door bonding in this embodiment mainly includes a material preparation unit, a core board glue spraying unit, a panel glue spraying unit, a flipping unit, a conveying unit, a central processing unit, and a cloud server unit. The material preparation unit stacks the fire door core board 2 and the fire door panel 13 to a fixed area according to the specified requirements; the core board glue spraying unit realizes the fire door glue spraying process and bonding treatment; the panel glue spraying unit realizes the fire door panel glue spraying Processing; the turning unit realizes the turning process after the fire door is glued; the conveying unit realizes the grabbing and moving of the fire door core board 2 and the fire door panel 13 and the output of the product. The material preparation unit, core board glue spraying unit, panel glue spraying unit, flipping unit and conveying unit are all conne...

Embodiment 2

[0075] Such as figure 1 As shown, an intelligent production system for fireproof door bonding in this embodiment mainly includes a material preparation unit, a core board glue spraying unit, a panel glue spraying unit, a flipping unit, a conveying unit, a central processing unit, and a cloud server unit. The material preparation unit stacks the fire door core board 2 and the fire door panel 13 to a fixed area according to the specified requirements; the core board glue spraying unit realizes the fire door glue spraying process and bonding treatment; the panel glue spraying unit realizes the fire door panel glue spraying Processing; the turning unit realizes the turning process after the fire door is glued; the conveying unit realizes the grabbing and moving of the fire door core board 2 and the fire door panel 13 and the output of the product. The material preparation unit, core board glue spraying unit, panel glue spraying unit, flipping unit and conveying unit are all connec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap