Bottom-mounted middle die assembly for tablet press

A technology for tablet press and die assembly, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of reducing the occurrence rate of production accidents, easy loosening of the middle mold, separation from the turntable, etc., so as to reduce production accidents. Occurrence rate, solving easy loosening, and overcoming the effect of middle mold movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

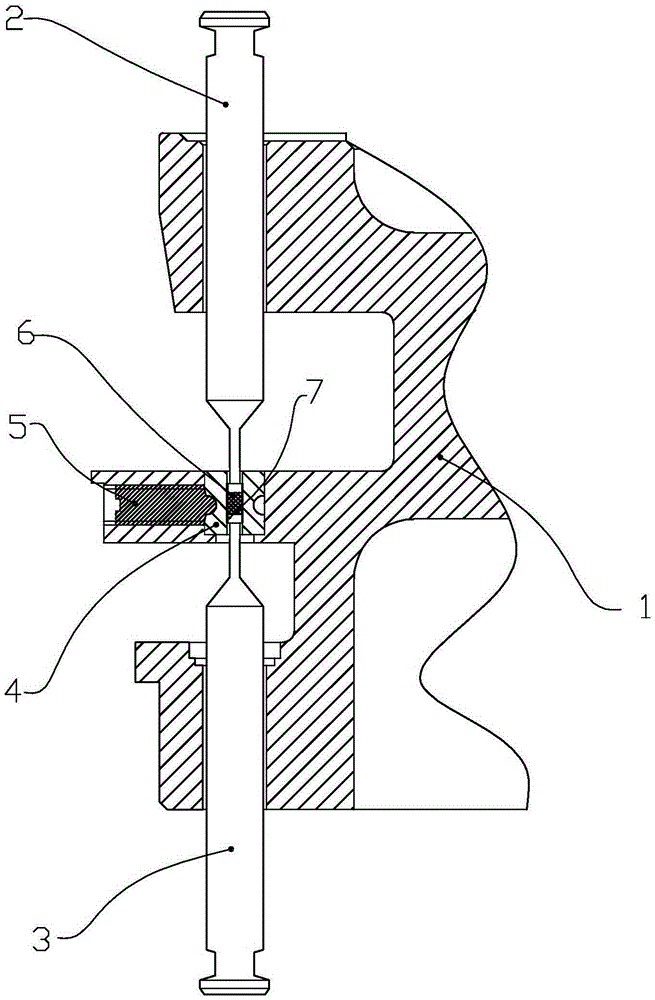

[0026] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

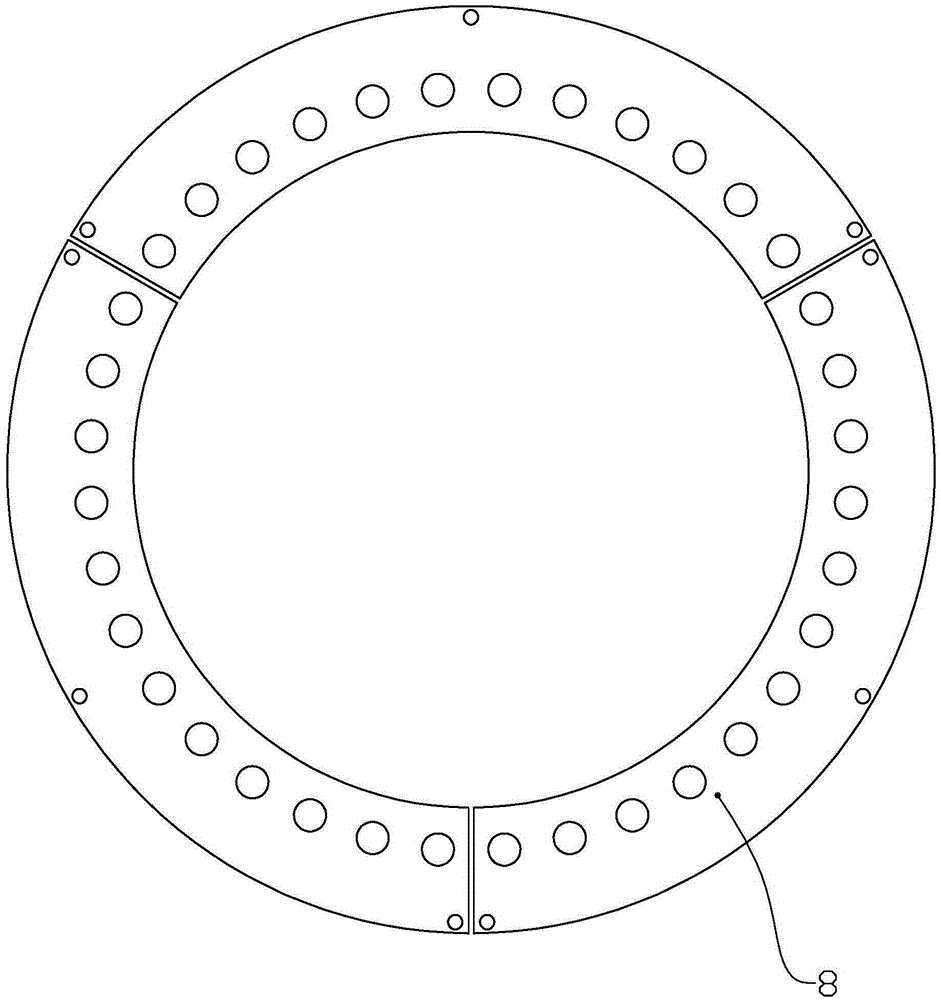

[0027] like Figure 2 to Figure 4 As shown, a bottom-mounted middle mold assembly of a tablet press includes a turntable 1 , a middle mold 4 and three pallets 8 .

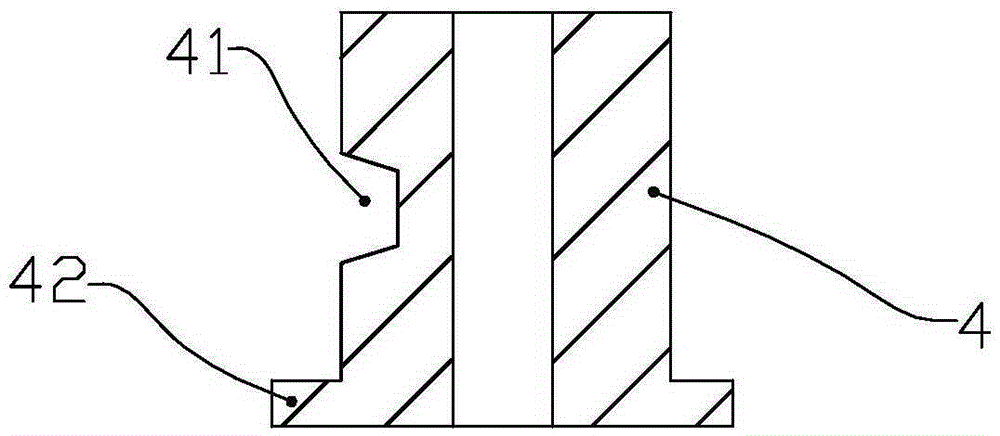

[0028] like Figure 4 As shown, the middle mold mounting hole on the boss in the middle of the turntable 1 is a vertical through hole, and a counterbore is arranged at the lower end of the through hole. like figure 2 , Figure 4 As shown, the middle mold 4 is in the form of a cylinder and a flange 42 is provided at the lower end, which may be an annular flange, so that the outer diameter of the annular flange is consistent with the inner diameter of the counterbore on the turntable. A groove is set on the annular side wall of the middle mold 4, and correspondingly, on the middle boss of the turntable 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com